Wedge side-shaping die

A technology of side shaping and wedge, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of outer surface deformation, difficult outer surface, etc., to improve quality, avoid deformation of parts, and avoid scratches. The effect of the outer surface of the piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

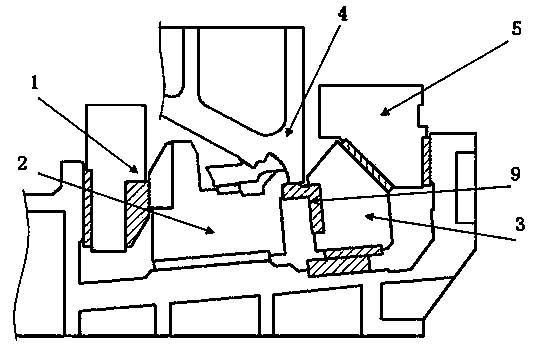

[0040] Example 1: By Figure 5 As shown, it is a schematic diagram of the mold retracting state of the present invention. At this time, the first oblique wedge driving block 1 and the second oblique wedge driving block 5, the rotary sub-binder core 6 and the female binder core 7 are all in a non-working state.

[0041] When the mold moves downward to work, the following describes the order in which the working parts involved in the present invention start to work:

[0042] The first stage: such as Image 6 Shown is the state in which the first oblique wedge drive block 1 of the present invention has completed driving the punch 2. In this process, the mold drives the first oblique wedge drive block 1 to move downward to drive the punch 2 to move to the predetermined position for workpiece processing After that, the first oblique wedge driving block 1 continues to move downward with the mold, and the punch 2 no longer moves in the oblique wedge working direction, and is in the residen...

Embodiment 2

[0048] by Picture 10 Shown is a schematic diagram of the retreat state of the mold of the present invention. At this time, the first oblique wedge driving block 21 and the second oblique wedge driving block 25, the sliding wedge-type sub-pressing core 26 and the mother pressing-material core 27 are all in a non-working state .

[0049] When the mold moves downward to work, the following describes the order in which the working parts involved in the present invention start to work:

[0050] The first stage: such as Picture 11 Shown here is the state where the first oblique wedge drive block 21 of the present invention has completed driving the punch 22. During this process, the mold drives the first oblique wedge drive block 21 to move downward to drive the punch 22 to move to a predetermined position for workpiece processing After that, the first oblique wedge driving block 21 continues to move downward with the mold, and the convex mold 22 no longer moves in the direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com