Slab abrasive belt rice milling machine

A rice mill and abrasive belt technology, applied in grain processing, application, grain pod removal, etc., can solve the problems of high power consumption, high rate of rice germ loss, high rate of broken rice, and reduce the rate of broken rice and achieve overall softness. , the effect of improving the shelling rate

Inactive Publication Date: 2014-05-28

彭才贵

View PDF6 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing rice milling technology uses a drum milling room to process rice, whether it is vertical or horizontal, the existing processing methods have many disadvantages, such as high power consumption, high rate of broken rice, and high loss rate of rice germ

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

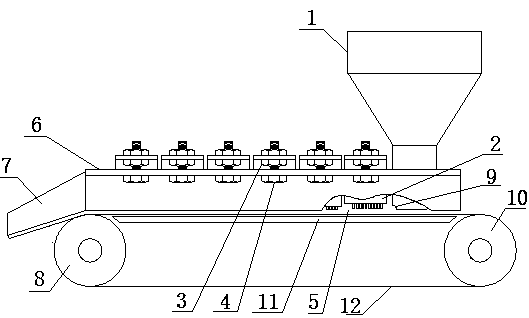

Login to View More Abstract

The invention discloses a slab abrasive belt rice milling machine which comprises a hopper, a discharging barrel and a machine frame. A straight-going rice milling channel is formed inside the machine frame. An abrasive belt transmission mechanism is arranged in the length direction of the rice milling channel. The abrasive belt transmission mechanism comprises a driving wheel, a driven wheel and an abrasive belt matched with the driving wheel and the driven wheel. A rice cutter is arranged on the rice milling channel. The blade end of the rice cutter is opposite to the abrasive belt, and a gap is reserved between the blade end of the rice cutter and the abrasive belt. The hopper is communicated with one end of the rice milling channel through a feeding head at the lower end of the hopper. The discharging barrel is communicated with the other end of the rice milling channel. The slab abrasive belt rice milling machine is high in rice milling efficiency and low in power consumption, meanwhile, the rate of remaining germs is high, and the broken rice rate is low.

Description

technical field The invention relates to grain processing machinery, more specifically to a flat abrasive belt rice mill. Background technique The existing rice milling technology uses a drum milling room to process rice, whether it is vertical or horizontal, the existing processing methods have many disadvantages, such as high power consumption, high rate of broken rice, and high loss rate of rice germ . The germ of rice is rich in nutrients such as vitamins, plant fibers and trace elements necessary for the human body. The finer and whiter the better, germ rice is more and more popular among people. Therefore need to improve existing rice milling machine, to reduce the loss of rice germ in the rice milling process. Contents of the invention The object of the present invention is to provide a flat abrasive belt rice mill, which has high rice milling efficiency, low power consumption, high germ retention rate and low broken rice rate. The flat abrasive belt rice mill...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B02B3/00

Inventor 彭才贵

Owner 彭才贵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com