Dough twist making machine

A twist machine and twist technology, applied in baking, baked food, food science, etc., can solve the problems of not being able to meet market needs, few uses, and low production efficiency, and achieve excellent non-stick properties, reduce production costs, and increase productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

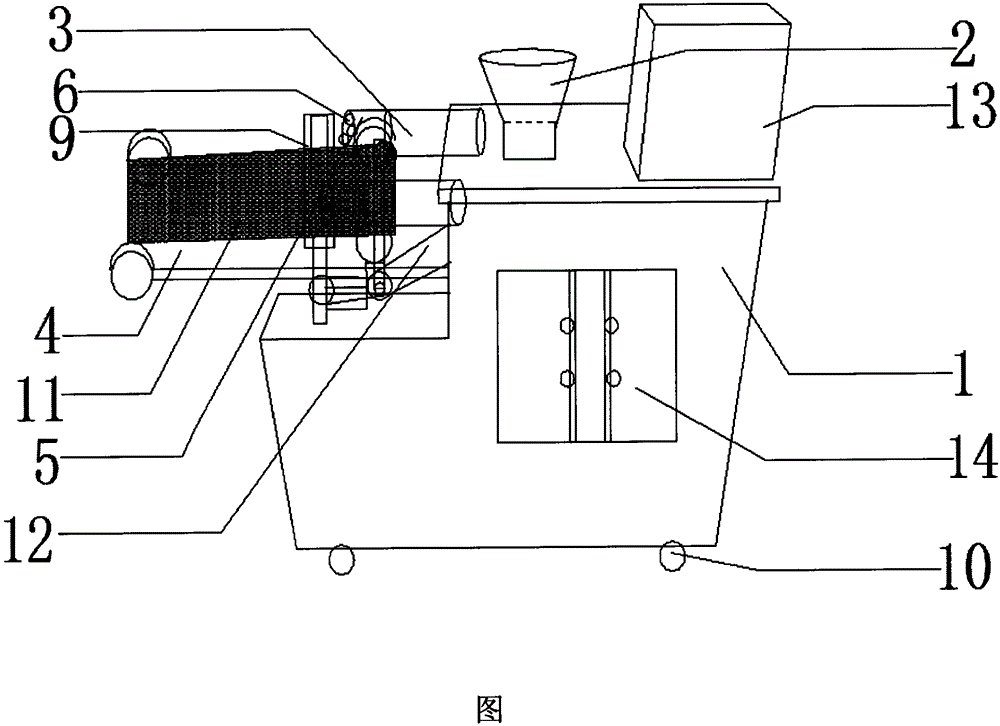

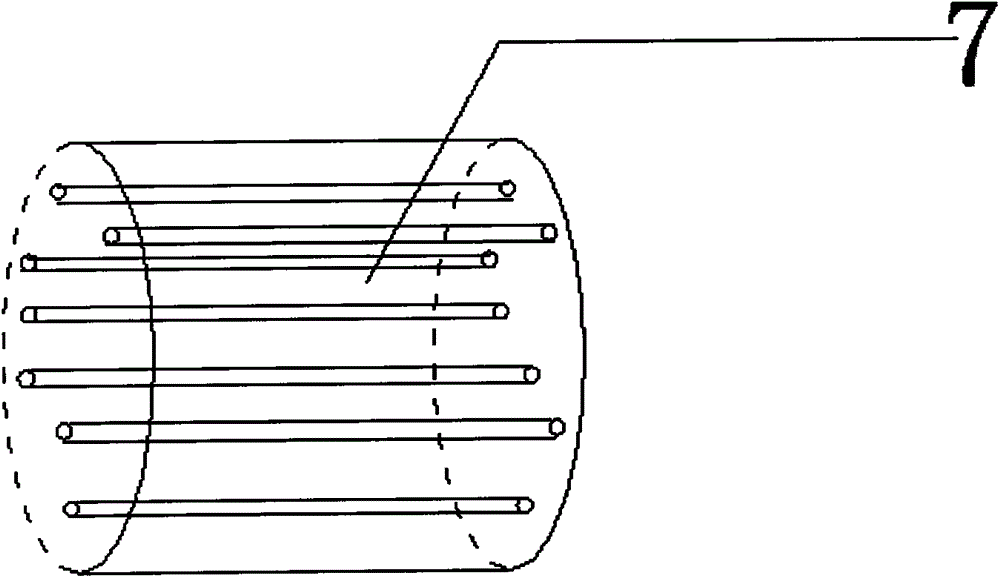

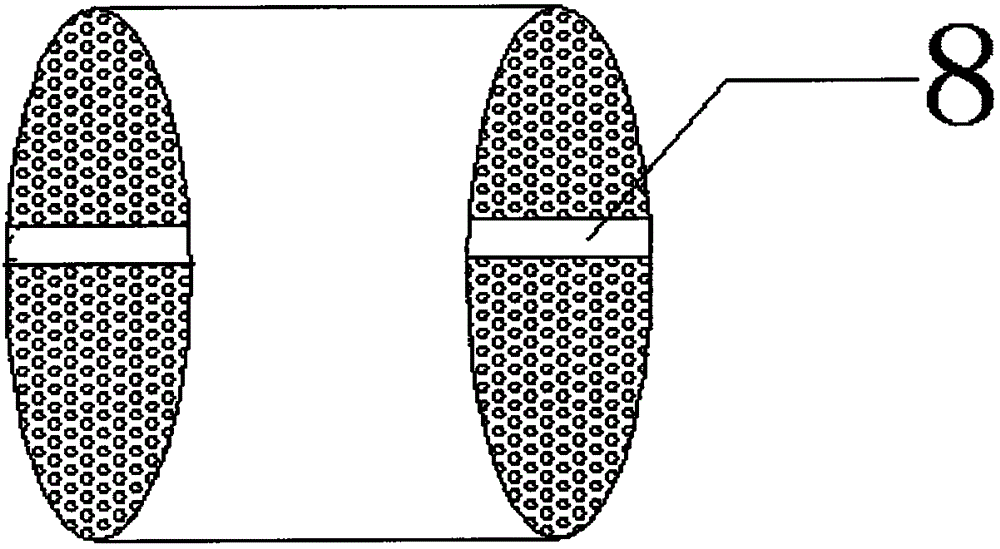

[0015] Such as figure 1 As shown, a twist machine includes a base 1, a kneading mechanism 2, an extrusion mechanism 3, and a twist conveying mechanism 4. The kneading mechanism 2 is arranged on the base 1, and the twist conveying mechanism 4 is connected to the base One is connected by a chain 12, the base is provided with a microwave oven 13, the size of the microwave oven is 25-30cm in length, 20-25cm in width, and 15-20cm in height, and a forming cylinder 5 is provided on the extrusion mechanism 2 ,Such as figure 2 with image 3 As shown, the forming tube can be a twist tube 6, a noodle tube 7 or a dough tube 8, such as figure 1 As shown, the two sides of the twist conveying mechanism are equipped with automatic cutters 9, and the base is also provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com