Method for the retarded coking of petroleum residues

A delayed coking method and residual oil technology, applied in coking carbonaceous materials, cracking, coking ovens, etc., can solve the problems of uncontrollable light oil quantity and quality, carburization, shortening the interval time of delayed coking units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 (prototype based)

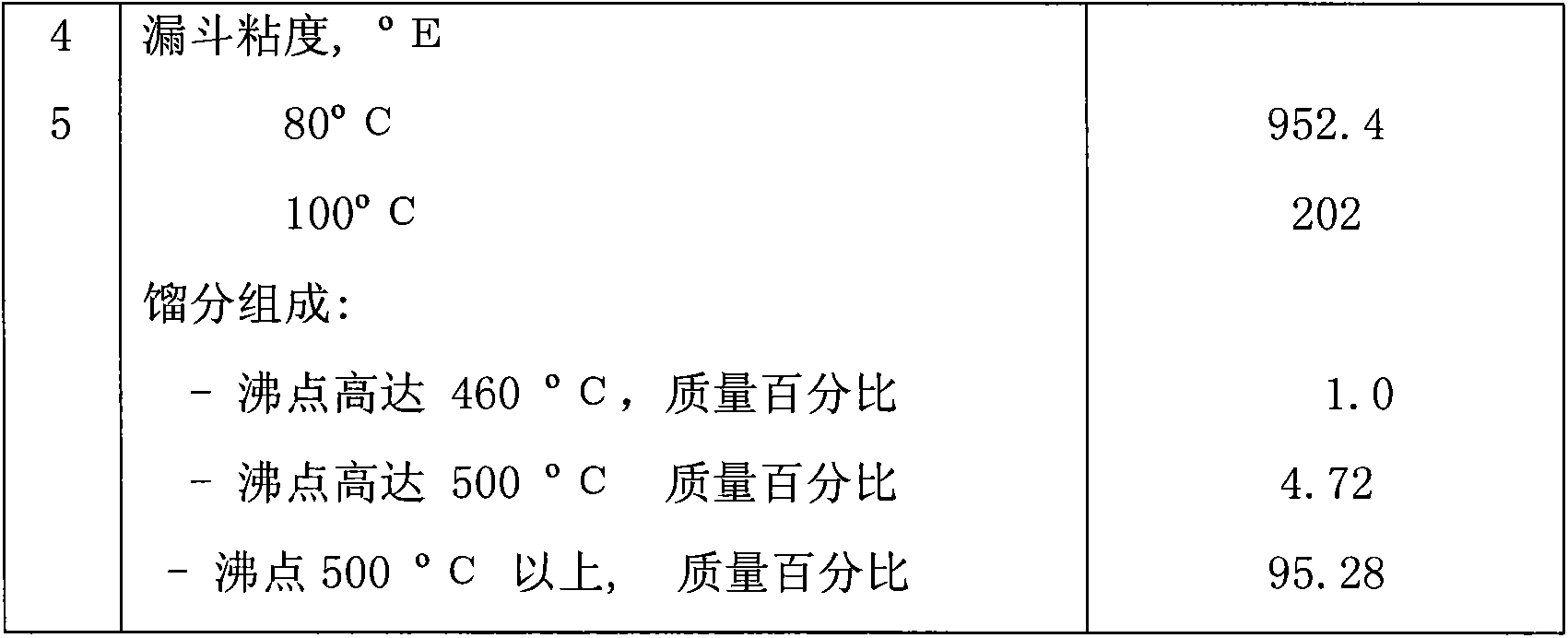

[0025] In industrial units, the coking feedstock, whose characteristics are listed in Table 1. The raw material is heated to 270°C in the heat exchanger and then sent to the bottom of the evaporator. In the upper part of the evaporator, the bottom liquid from the main rectification column is used as a recycle, and its amount is 10% of the raw material amount. The secondary raw material formed in this way in the evaporator is heated to 500°C in the furnace and sent to the carbonization chamber for coking. Coking products in the carbonization chamber enter the lower part of the main rectification tower through the top gas pipeline of the rectification tower. The coking product with the highest boiling point is condensed in the top mass exchange device in the lower part of the rectification tower, and the cold heavy coking gas oil is used as the reflux medium in the lower part, and the dosage is 10% of the raw material. All concentrated hig...

Embodiment 2

[0027] Embodiment 2 (according to the method proposed by the present invention).

[0028]According to the accompanying drawings, the characteristics of coker oil raw materials are shown in Table 1. The feedstock is heated to 270°C in heat exchange and then sent to the evaporator where heavy coker gas oil is provided as recycle in the top tray of the evaporator, which is used in an amount of 10% of the feedstock. The secondary raw material obtained at the bottom of the evaporator is heated to 500°C in the furnace, and then transported to the carbonization chamber for coking. The coked product is sent to the bottom of the rectification column through the upper pipeline. In order to adjust the final boiling point of the heavy coker gas oil separated from the device, the cooled heavy gas oil is provided as the lower reflux medium, and its consumption is 10% of the raw material, which is transported into the first mass exchange device at the bottom of the rectification tower. In ...

Embodiment 3

[0033] Embodiment 3 (method proposed according to the present invention)

[0034] Under this example, the aim is to increase the yield of heavy gas oil relative to Example 2, wherein the quality of this heavy gas oil can be used as a feedstock for hydrocracking.

[0035] To achieve this purpose, similar to Example 2, coking the raw material, but reducing the amount of heavy gas oil entering the mass exchange device at the bottom of the rectification tower as reflux to 5% volume content, and supplying the mass exchange device at the top of the rectification tower The amount of light gas oil is the same as in Example 2.

[0036] The coking results are shown in Table 2.

[0037] It can be seen from Example 3 that, compared with Example 2, the reduction in the amount of the lower reflux medium (i.e., the reflux medium supplied to the first mass exchange device at the bottom of the rectification column) results in the supplied heavy coking gas being formed from the fraction in We...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com