Steam vortex shedding flowmeter measuring multiple parameters

A vortex flowmeter, multi-parameter technology, applied in the direction of volume/mass flow generated by electromagnetic effect, volume/mass flow generated by mechanical effect, dynamic effect by detecting fluid flow, etc., can solve the problem of inability to measure steam temperature and pressure. and density and accurate mass flow, unable to measure temperature and pressure at the same time, poor high temperature resistance, etc., to achieve the effect of compact structure, low manufacturing cost and long product life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

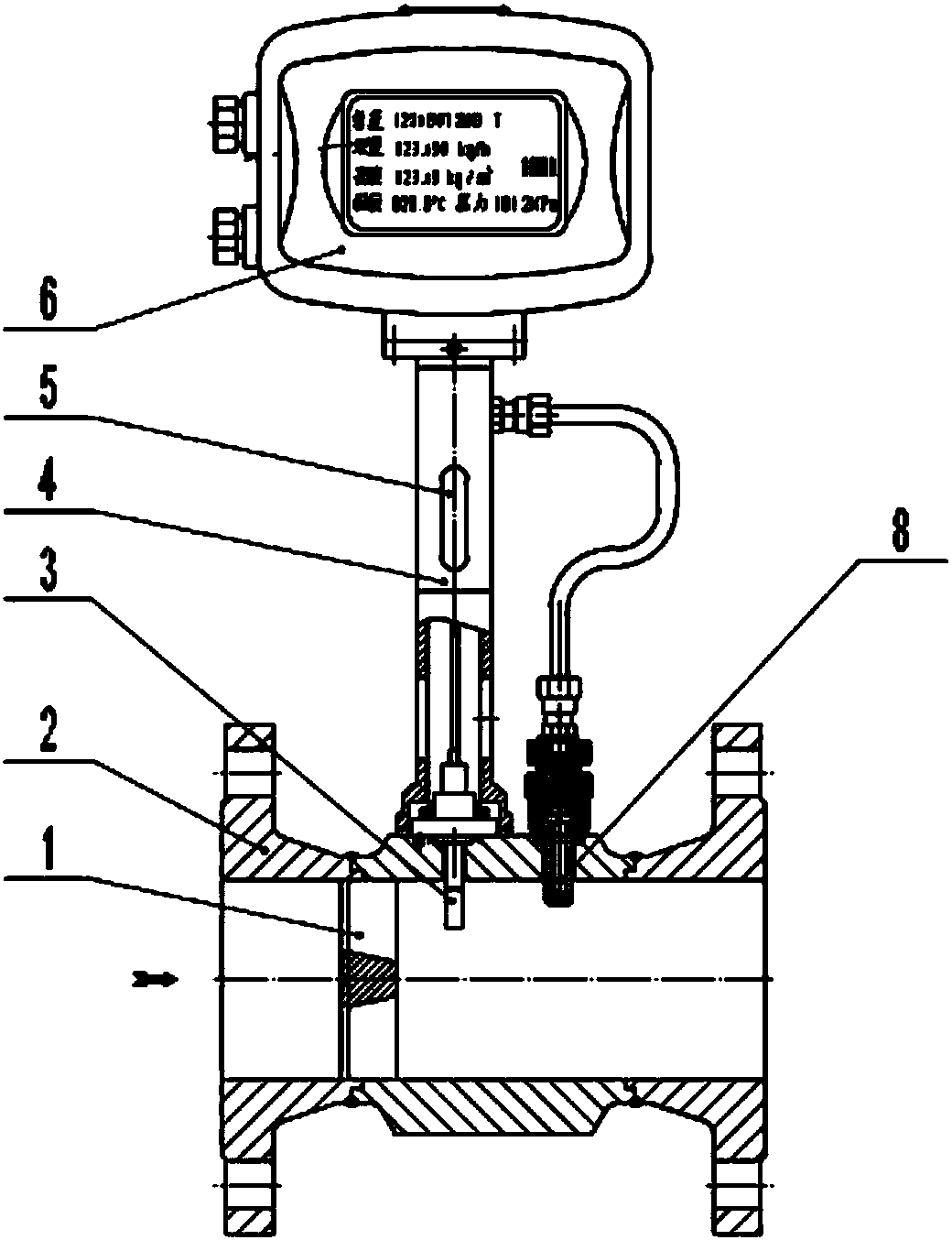

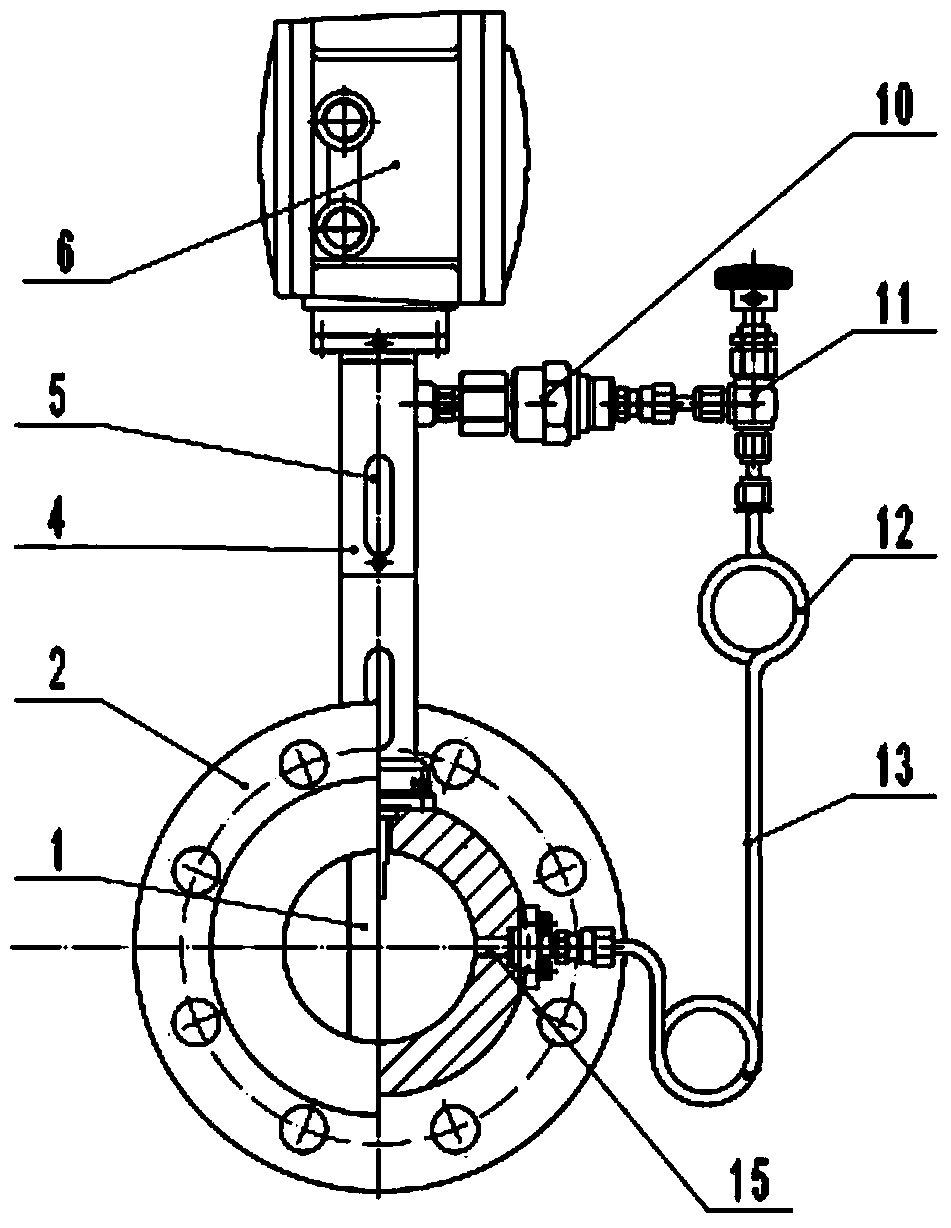

[0015] like figure 1 , 2 As shown, a steam vortex flowmeter for multi-parameter measurement includes a surface body 2 with a measuring tube, a vortex generator 1, a flow sensor 3, a flow totalizer 6, a temperature sensor 8 and a pressure sensor 10. The vortex generating body 1 is installed in the inner hole of the meter body 2 with the measuring tube, and the flow sensor 3 is installed on the outside of the meter body 2 with the measuring tube and directly behind the vortex generating body 1. A support column 4 is installed above the meter body 2, the support column 4 covers the flow sensor 3, the flow totalizer 6 is installed on the upper end of the support column 4, and the pressure sensor 10 Installed on the front side of the upper part of the support column 4, there is a pressure sensor pressure hole 15 on the outside of the meter body 2 with the measuring tube and at a 90-degree left corner of the section where the flow sensor 3 is located. The pressure sensor 10 The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com