Robotic Bionic Hydraulic System

A hydraulic system and robot technology, applied in the field of bionic hydraulics, can solve problems such as high cost, high operating conditions, and poor flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

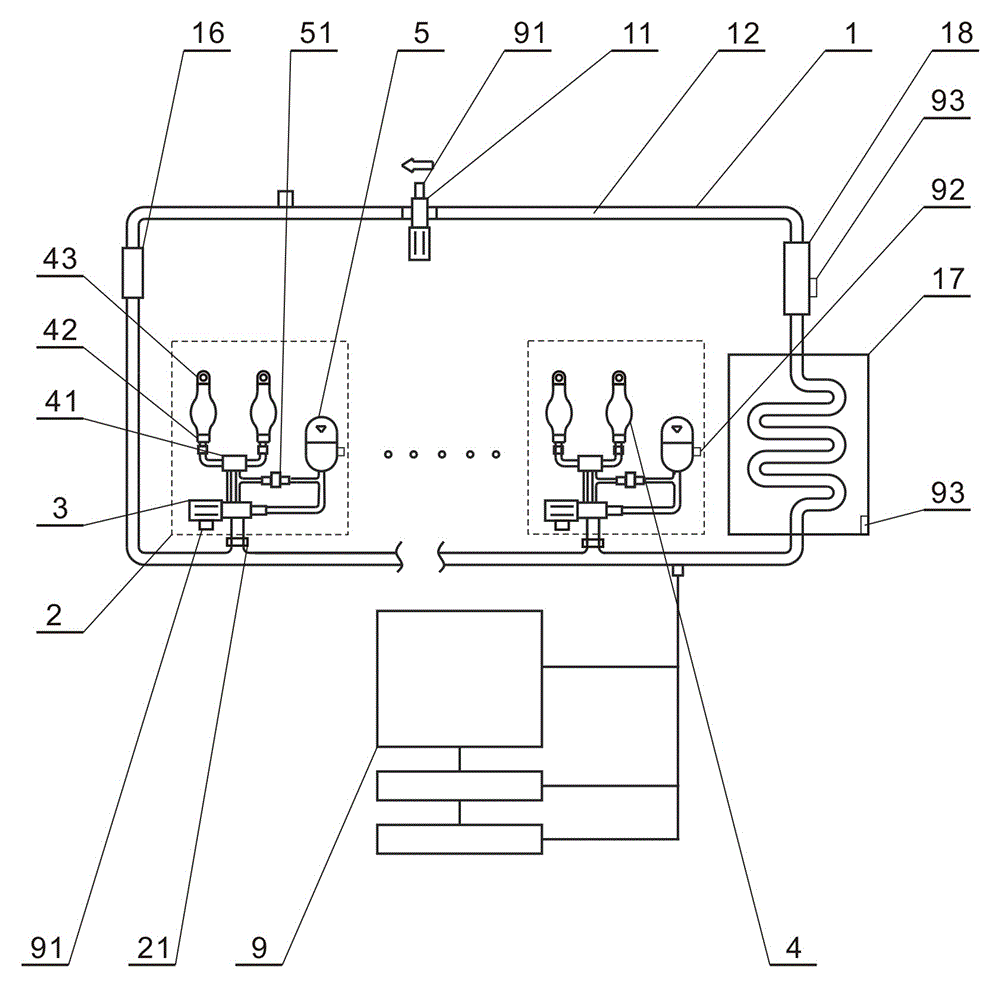

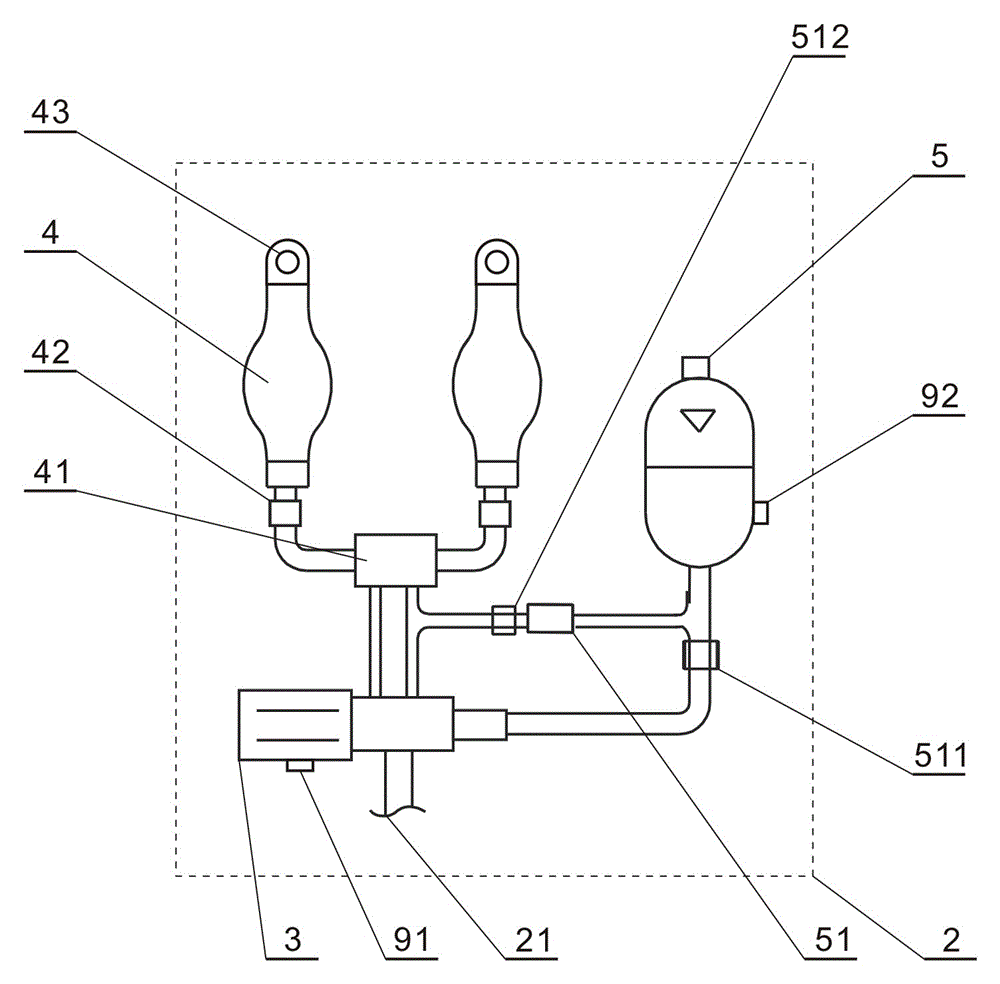

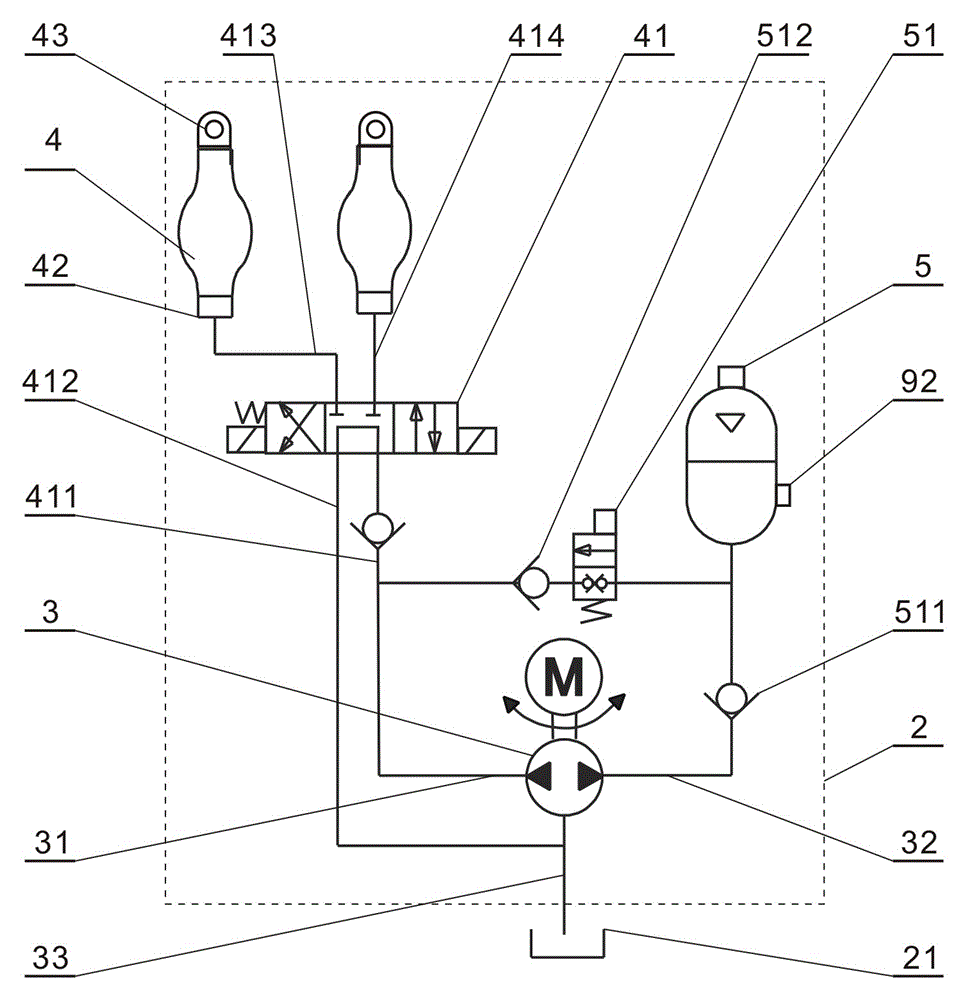

[0032] The present invention is a robot driving system with hydraulic pressure as the driving source, which is used to control and complete various body movements of the robot, such as walking, running, jumping or falling, etc., so that the body movement of the robot can simulate the movement of the human body or animal body and has biomechanical properties.

[0033] The composition of the technical solution of the present invention includes a hydraulic oil supply circulation system 1 , several bionic execution units 2 and a CPU central controller 9 .

[0034] The hydraulic oil supply circulation system 1 of the present invention includes an oil delivery pump 11, an oil circuit 12, a filter 16, a temperature regulator 17, an electrostatic oil purifier 18, and a bionic execution unit access point 21. The output end is sequentially connected to the filter 16, the access point 21 of the bionic execution unit, the temperature regulator 17, the electrostatic oil purifier 18, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com