Supercharger oil inlet gasket for engine test run

A supercharger and engine technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of supercharger bearing wear, jamming, oil leakage, etc., to improve work efficiency, avoid early wear, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

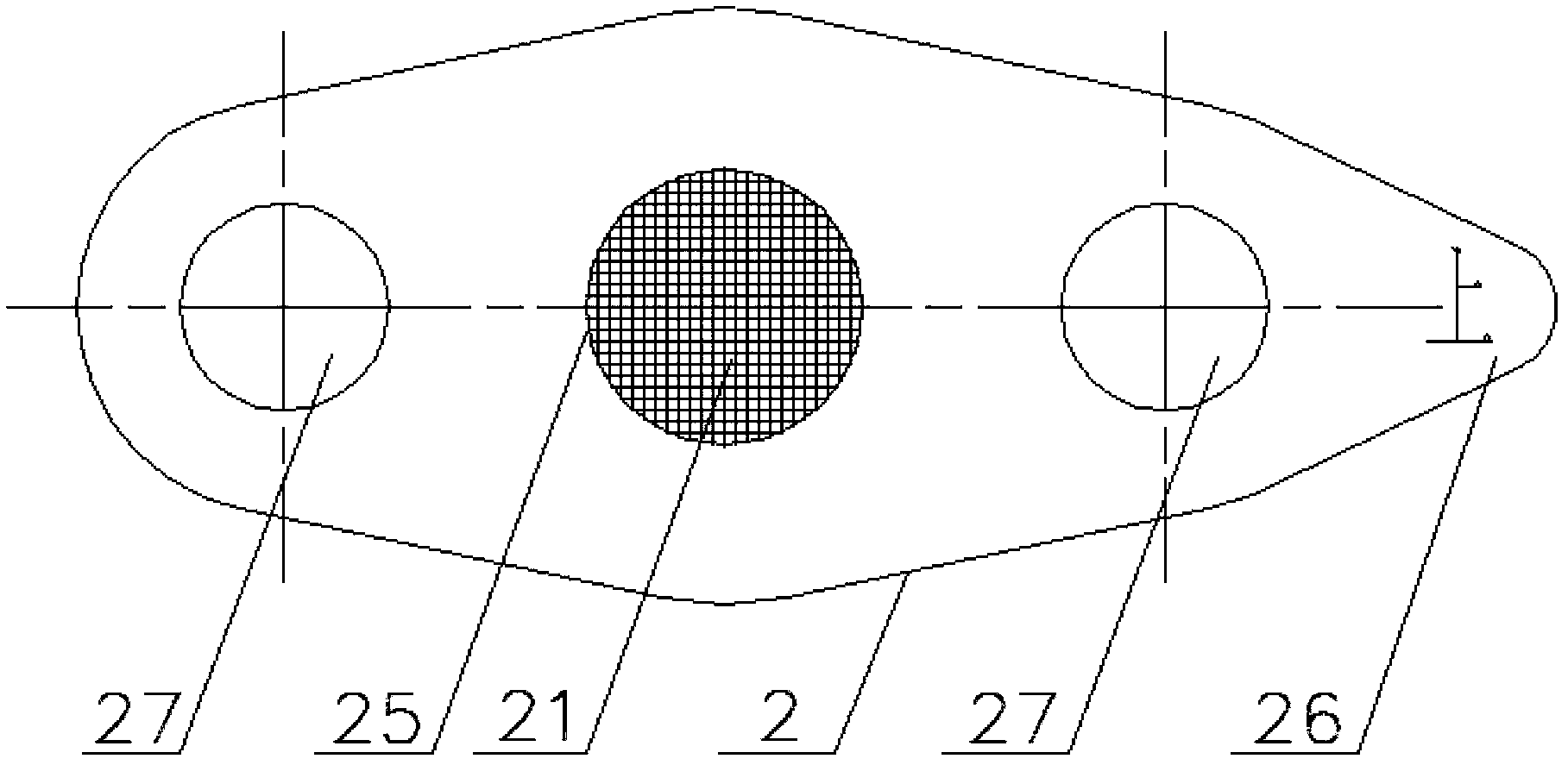

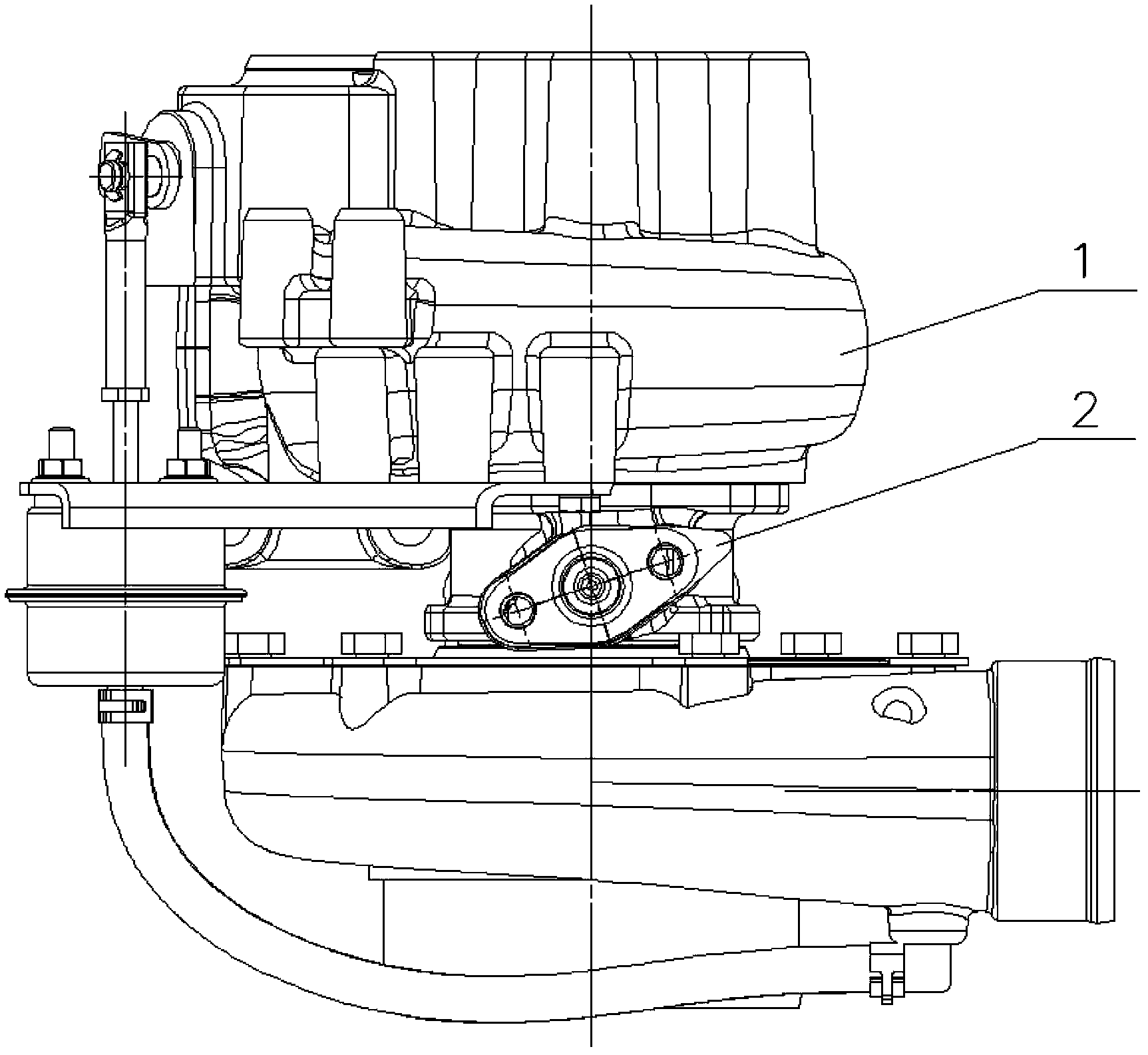

[0023] Such as figure 1 As shown, a supercharger oil inlet gasket 2 used for engine testing according to the present invention has a filter screen 21 for filtering impurities in the oil at its oil inlet 25 . "UP" or other markings are printed on one side of the gasket. One end of the spacer is designed as convex circle 26, which is convenient for disassembly and assembly. In addition, the spacer is provided with a mounting hole 27, through which the spacer is installed and fixed during use.

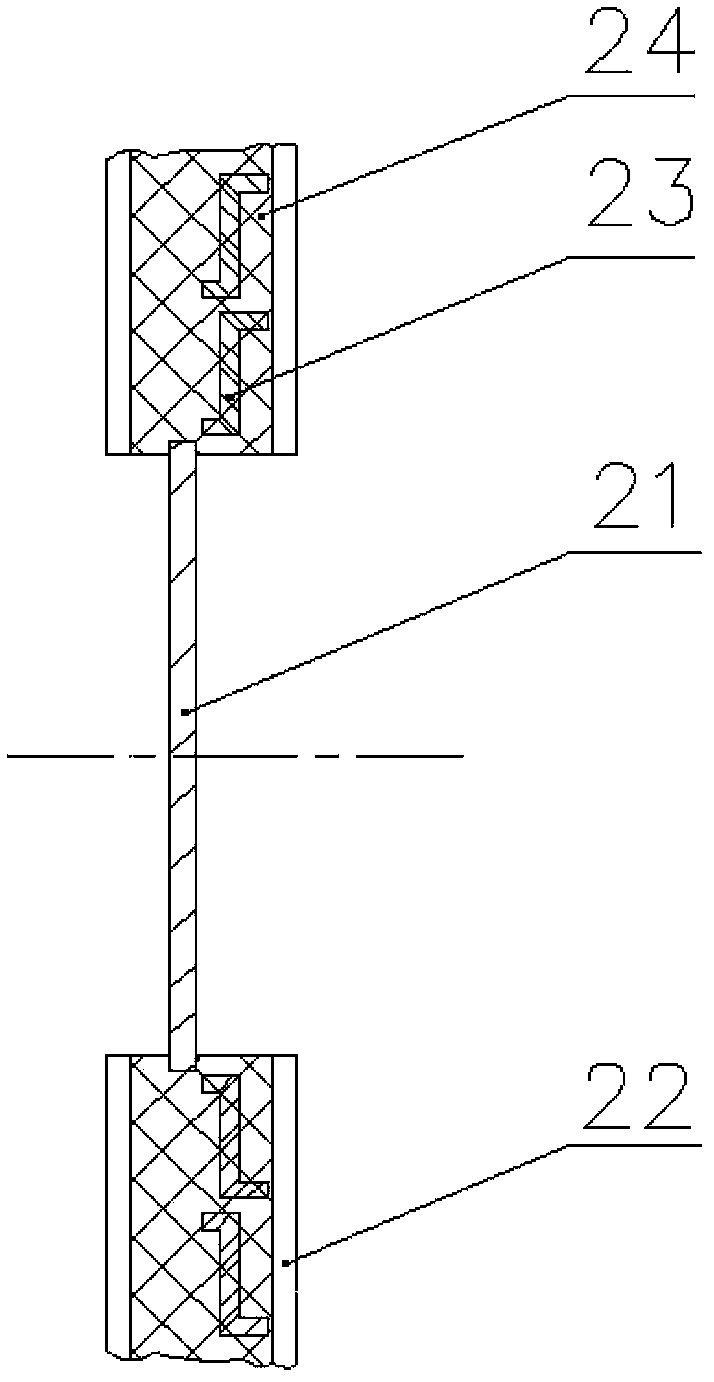

[0024] The supercharger oil inlet gasket of the present invention adopts a multi-layer structure, such as figure 2 As shown, aluminum sheet 22 is used on the upper and lower surfaces, and its thickness is about 0.25mm. Betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com