Hydraulic setting small diameter tubing bridge plug

A hydraulic setting and small-diameter technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of reducing construction efficiency, unsuitable for large-scale promotion and application, and increasing construction costs, etc., to achieve Reduce the probability of encountering resistance and jamming, adapt to a wide range of temperatures, and block a large range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

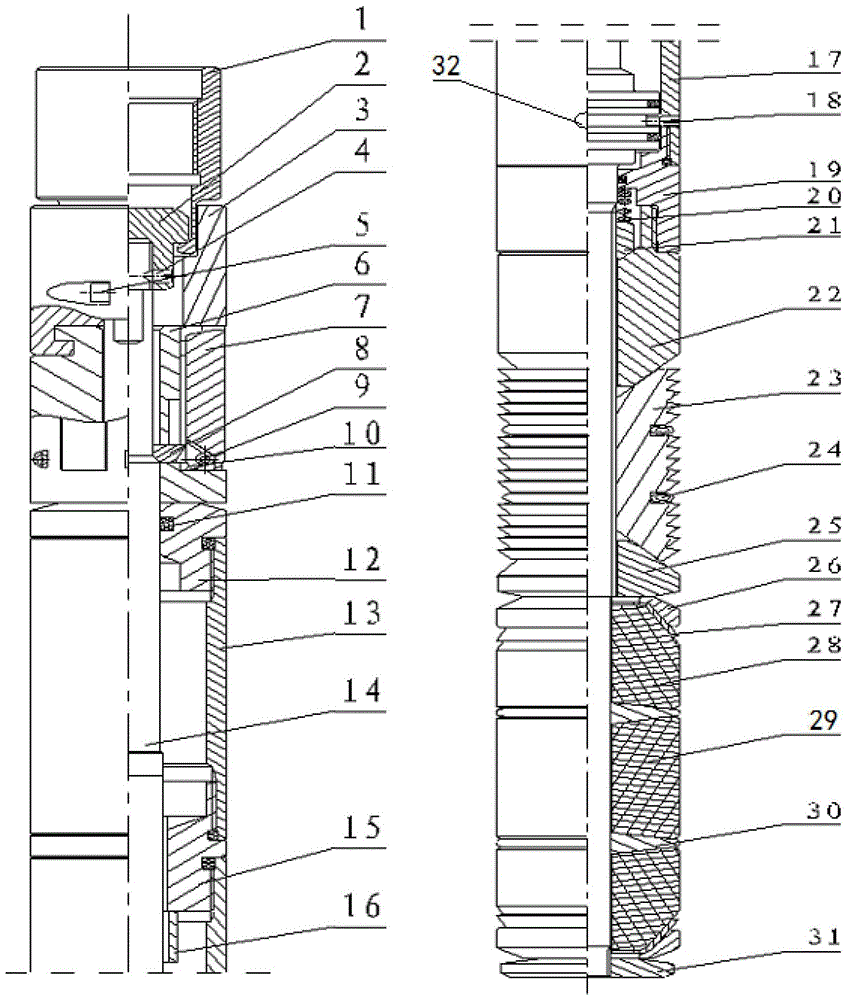

[0013] The small-diameter tubing bridge plug is mainly composed of a hand joint 1, a connecting head 2, a ferrule 3, a set screw 4, an inner hexagon screw 5, a positioning support seat 6, a claw 7, a positioning block 8, a cotter pin 9, a twist Spring 10, sealing ring 11, sealing end cover 12, outer cylinder 13, mandrel 14, connection sleeve 15, elastic limit sleeve 16, shear sleeve 17, shear pin 18, lock ring outer cylinder 19, lock ring spring 20, Lock plate 21, slip upper seat 22, slip 23, fixed spring 24, slip lower seat 25, rubber cartridge seat 26, rubber cartridge sheath 27, side rubber cartridge 28, center rubber cartridge 29, spacer ring 30 and nut 31 Etc. composition:

[0014] The lower part of the outer wall of the drop joint 1 penetrates the ferrule 3, the locking claw at the bottom of the inner wall catches the connector 2, and the inner wall of the connector 2 is threaded to the top of the mandrel 14 that runs through the center of the overall bridge plug, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com