Assembled road steel bridge overall track erection and push system and process

A prefabricated, steel bridge technology, applied in the direction of erecting/assembling bridges, bridge construction, bridges, etc., can solve the problems of long bridge erection time, affecting the stability of steel bridges, shortening erection time, etc., to achieve high erection efficiency and erection time. Short, easy to erect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

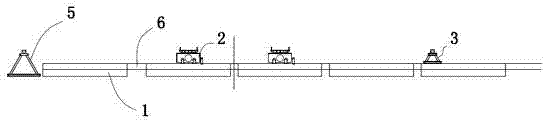

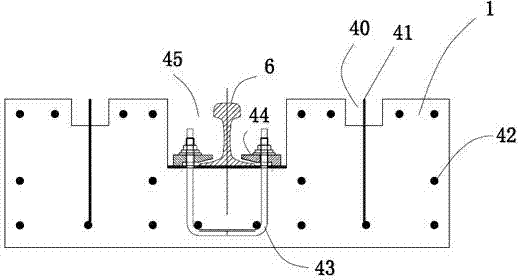

[0053] Example: a prefabricated highway steel bridge integral track erection and push system, the prefabricated highway steel bridge is a cable-stayed fabricated highway steel bridge, with ZB-200 type prefabricated highway steel bridge as the main beam 9, and the main beam passes through the tower The truss 8 in the beam consolidation area is fixed with a cable tower 7, and the cable tower is a "321" assembled highway steel bridge structure. The erection system consists of two parallel rail systems (see appendix figure 1 attached figure 2 ), each track system consists of several sections of concrete pads 1 laid on land (see appendix image 3 ) and a steel rail 6 that is fixedly laid on the concrete pad to form a whole, and the laying position of the concrete pad is directly below the main beam of the land span after the steel bridge is erected. Four traction trolleys 2 fixed with the steel bridge are placed on the two tracks, and a rolling support frame with a rolling top i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com