Low-sensitivity glycosylation whey protein hydrolysate and preparation method thereof

A whey protein hydrolysis and whey protein technology, which is applied in the field of hypoallergenic glycosylated whey protein hydrolyzate and its preparation, can solve the problems of few research reports and insufficient attention, and achieves increased nutritional content, The effect of reducing antigenicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

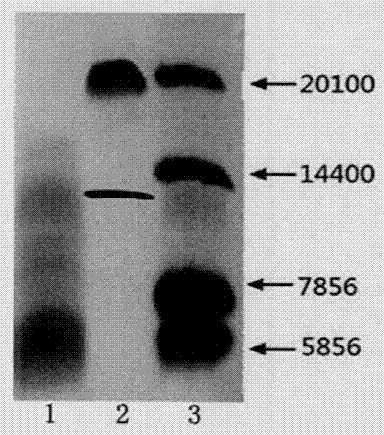

Image

Examples

Embodiment 1

[0027] A preparation method of hypoallergenic glycosylated whey protein hydrolyzate, the preparation method comprising the following steps:

[0028] (1) Dissolving whey protein in water according to a weight ratio of 5-8% to obtain a whey protein solution;

[0029] (2) Hydrolysis: adjust the pH value of the whey protein solution to 7.0-8.0, add compound enzymes at a ratio of 3000-5000U / g protein, and hydrolyze for 1-2 hours at a temperature of 55°C-75°C to obtain hydrolyzed whey protein solution;

[0030] (3) dissolving sugar in the above-mentioned hydrolyzed whey protein solution according to the weight ratio of 10-15%, preparing a mixed solution, adjusting the pH value of the mixed solution to 7.0-8.0, and freeze-drying to obtain a protein-sugar mixture;

[0031] (4) Glycosylation: Glycosylation treatment is carried out on the protein sugar mixture at a relative humidity of 60% to 70% and a temperature of 55°C to 65°C for 24h to 48h to obtain glycosylated hydrolyzed whey pr...

Embodiment 2

[0046] This embodiment is a preferred solution on the basis of embodiment 1. The quality of the raw materials used is the same as that of embodiment 1, and the same part as embodiment 1 will not be repeated. Please refer to embodiment 1.

[0047] A preparation method of hypoallergenic glycosylated whey protein hydrolyzate, the preparation method comprising the following steps:

[0048] (1) dissolving whey protein in water according to a weight ratio of 5%, to obtain a whey protein solution;

[0049] (2) Hydrolysis: adjust the pH value of the whey protein solution to 7.5, add complex enzymes according to the ratio of 4000U / g protein, and hydrolyze at 65°C for 1.5h to obtain a hydrolyzed whey protein solution;

[0050] (3) dissolving sugar in the above-mentioned hydrolyzed whey protein solution according to a weight ratio of 5%, preparing a mixed solution, adjusting the pH value of the mixed solution to 7.5, and freeze-drying to obtain a protein-sugar mixture;

[0051] (4) Glyc...

Embodiment 3

[0084] This embodiment is a preferred solution on the basis of embodiment 1. The quality of the raw materials used is the same as that of embodiment 1, and the same part as embodiment 1 will not be repeated. Please refer to embodiment 1.

[0085] The composite enzyme described in the step (2) is a mixture of alkaline protease, neutral protease, papain, trypsin, flavor protease, protease A, protease M, and the ratio of parts by weight of each enzyme is:

[0086]

[0087] Further, the weight and number ratio of the maltoligosaccharide, glucose and phosphoryl oligosaccharide is:

[0088] Maltooligosaccharide 2

[0089] glucose 1

[0090] Phosphoryl oligosaccharides 0.5.

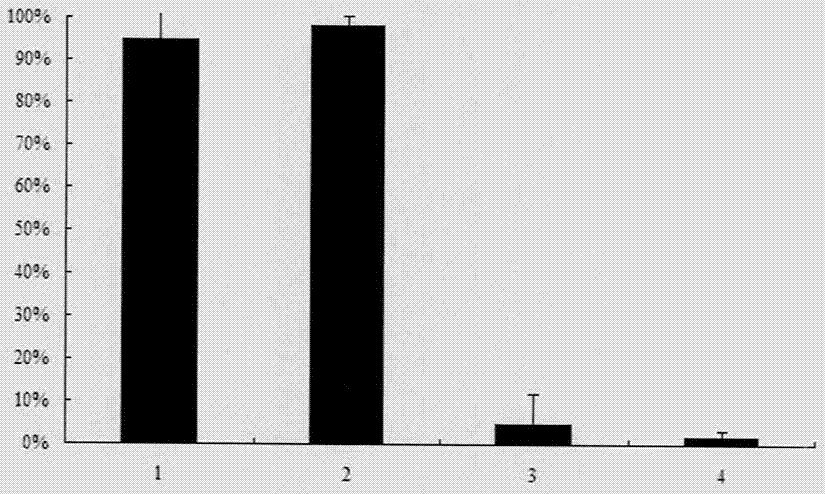

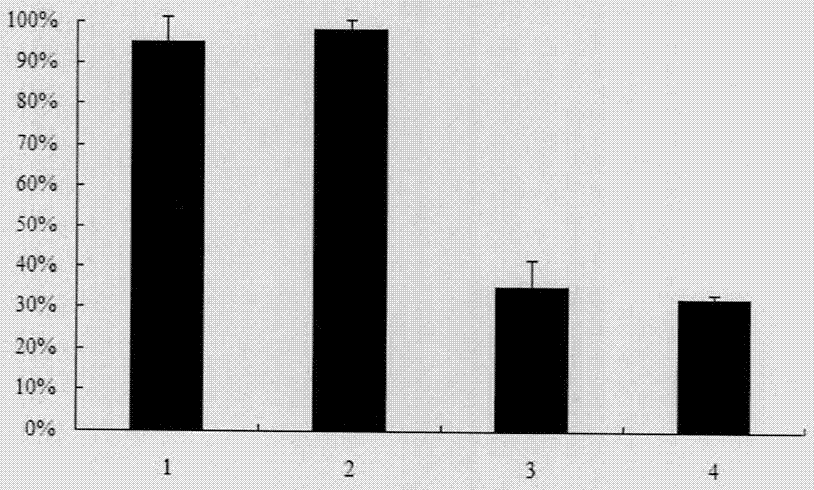

[0091] For specific inhibition rate results, see image 3 . The low-sensitivity glycosylated whey protein hydrolyzate obtained by the preparation method of this example was used as the experimental group, and the untreated whey protein was used as the control group. Compared with the control group, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com