High-temperature micro-aerobic-anaerobic digestion device and method for organic sludge

A technology of organic sludge and anaerobic digestion, applied in sludge treatment, biological sludge treatment, waste fuel, etc., can solve the problems of limited oxygenation, difficulty in reaching an aerobic state, and inability to release enough heat to save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

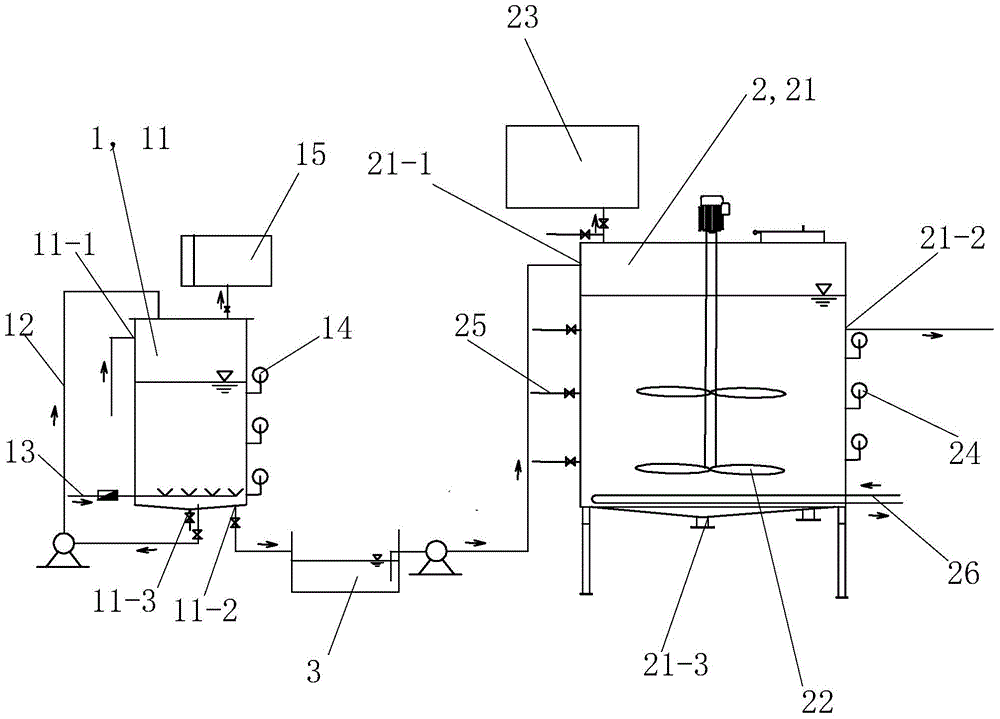

[0035] See figure 1 , The high-temperature micro-aerobic-anaerobic digestion device for organic sludge in this embodiment includes a self-heating high-temperature micro-aerobic reactor 1, an anaerobic fermentation reactor 2 and a pH adjustment tank 3. The pH adjustment tank 3 is arranged between the high-temperature micro-aerobic reactor 1 and the anaerobic fermentation reactor 2, and the outlet of the self-heating high-temperature micro-aerobic reactor 1 communicates with the pH adjustment tank 3 through a pipeline, and the pH value The adjustment tank 3 communicates with the feed port of the anaerobic fermentation reactor 2 through a pipeline and a pump.

[0036] The self-heating high-temperature micro-aerobic reactor 1 includes a reaction tank 11 , a sludge return system 12 , an aeration system 13 , a temperature sensor 14 and a gas absorption treatment device 15 .

[0037] The outer periphery of the reaction tank 11 is provided with an insulating layer, and the reaction t...

Embodiment 2)

[0068] The organic sludge high-temperature micro-aerobic-anaerobic digestion method of the present embodiment is identical with embodiment 1 except that:

[0069] Step ③ The organic sludge is subjected to high-temperature anaerobic digestion.

[0070] Open the valve connected to the pipeline, step ② releases the dissolved oxygen and is pumped into the anaerobic fermentation reactor 2 through the high-temperature micro-aerobic digestion sludge. The sludge stays in the anaerobic fermentation reactor 2 for 6-10 days to complete the anaerobic digestion process. The temperature of the high-temperature anaerobic digestion is 50°C-55°C, and the discharged sludge is directly used for agriculture after mechanical dehydration.

[0071] High-temperature anaerobic digestion can speed up the reaction rate. Part of the heat source for high-temperature anaerobic digestion comes from the self-heating type high-temperature micro-aerobic flow out of the sludge in the previous stage. The other ...

Embodiment 3)

[0074] The organic sludge high-temperature micro-aerobic-anaerobic digestion method of the present embodiment is identical with embodiment 1 except that:

[0075] The self-heating type high-temperature micro-aerobic reactor 1 also includes a defoaming system, and the defoaming system includes an air defoaming pipe and an injection port; A small hole; the injection port is installed on the top of the reactor body. When the defoaming system is working, the gas blown out through the small holes on the wall of the air defoaming pipe breaks the foam; the injection port can spray the defoamer, and the defoamer is sprayed into the reactor and evenly distributed by the agitator It acts as a defoamer on the entire liquid surface.

[0076] Steps of the digestion method ② During the high-temperature micro-aerobic digestion process of organic sludge, the defoaming system sends air into the reaction tank to break the bubbles generated in the reaction tank, so that the digestion process go...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com