Fuel tank structure of motorcycle

A technology for motorcycles and fuel tanks, applied in gasoline drums, bicycle accessories, transportation and packaging, etc., can solve the problems of single function, low utilization rate, easy air leakage, etc., to simplify the molding process, the parting surface is simple, and the material is saved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

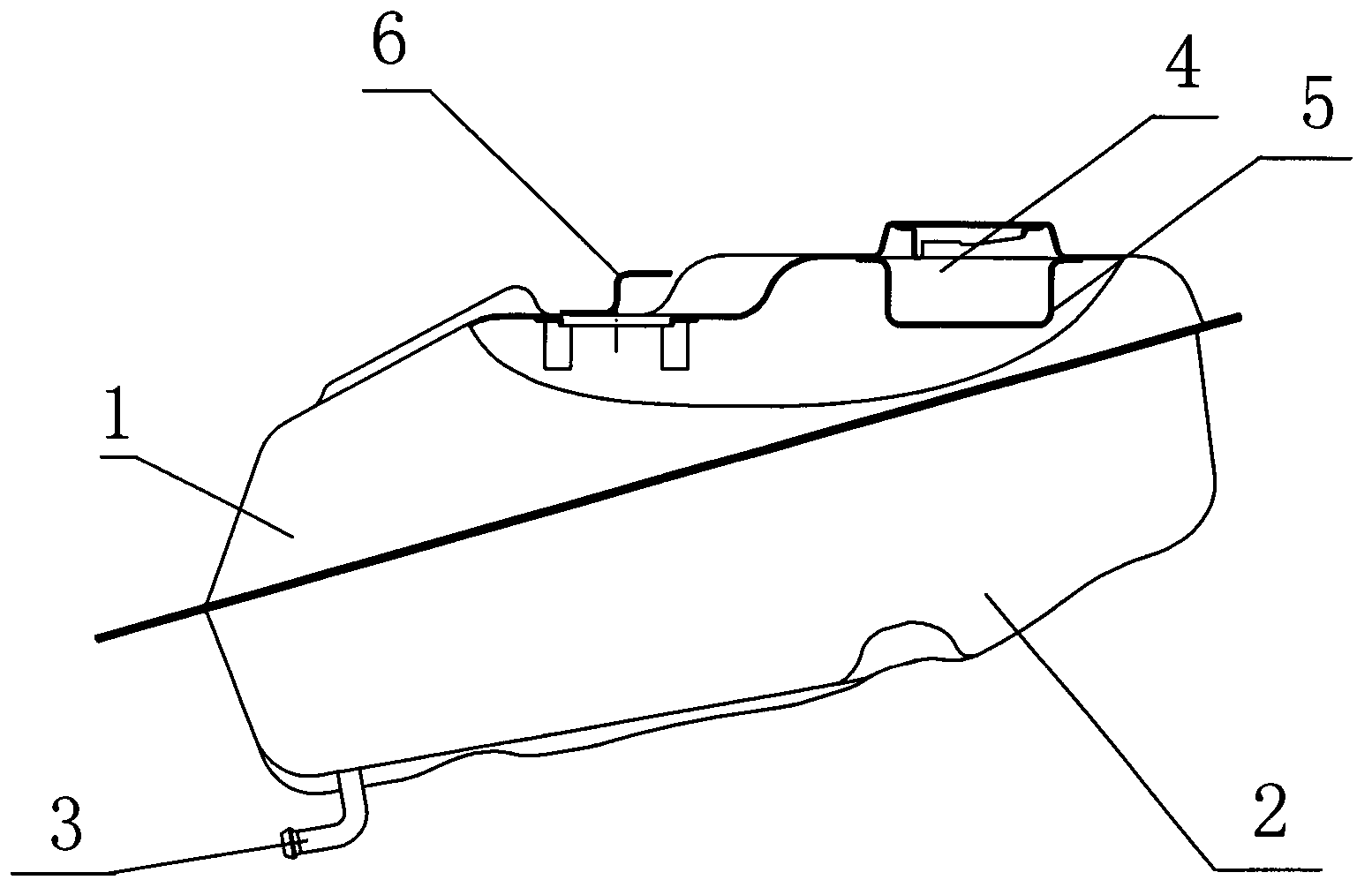

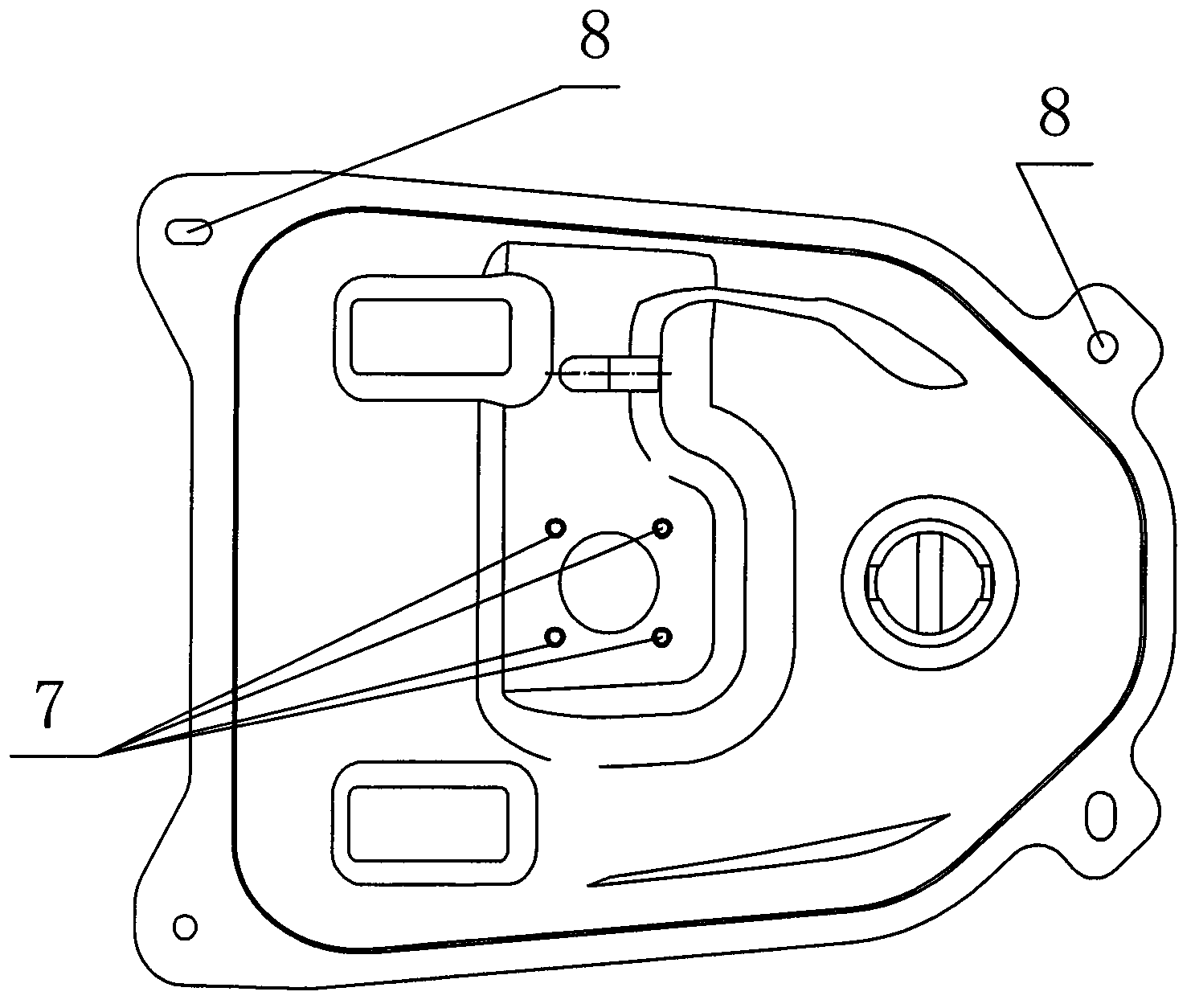

[0012] See attached figure 1 , 2 , the motorcycle oil tank structure of the present invention, comprises fuel tank upper casing 1 and fuel tank lower casing 2, and one end of its fuel tank upper casing 1 is provided with fuel filler 4, and the bottom of fuel filler 4 communicates with fuel tank lower casing 2; An oil retaining ring 5 for preventing oil from overflowing is provided between the fuel filler port 4 and the lower casing 2 of the fuel tank, so as to prevent the fuel from washing up to the rubber sealing ring of the fuel tank cap during the running of the vehicle and accelerate the aging of the sealing ring; the lower casing of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com