Arrangement structure of reinforcing ribs for back door trim panel

A technology for arranging structures and reinforcing ribs, which is applied to superstructures, subassemblies of superstructures, transportation and packaging, and can solve problems such as large shrinkage differences and large deformation of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

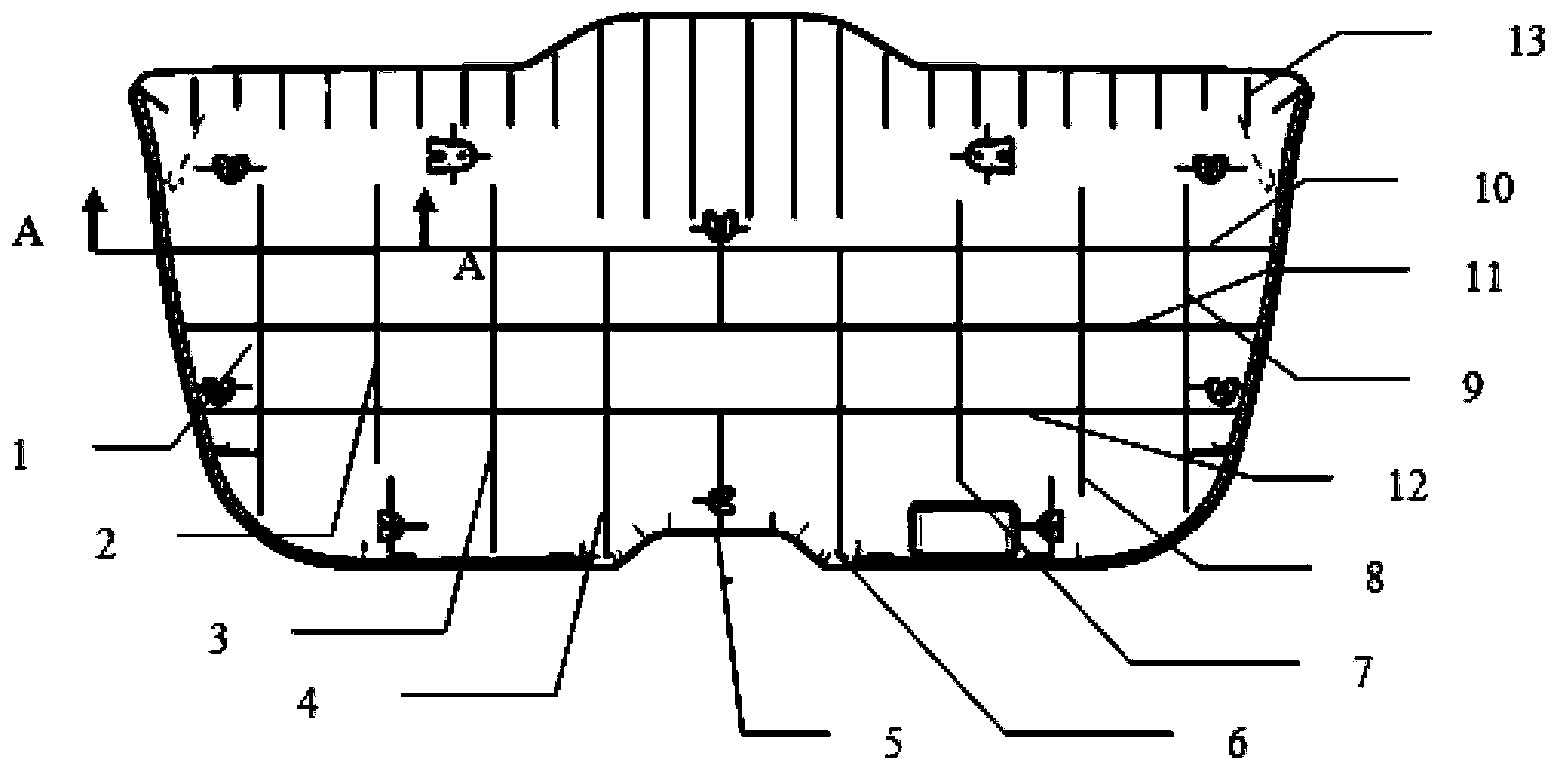

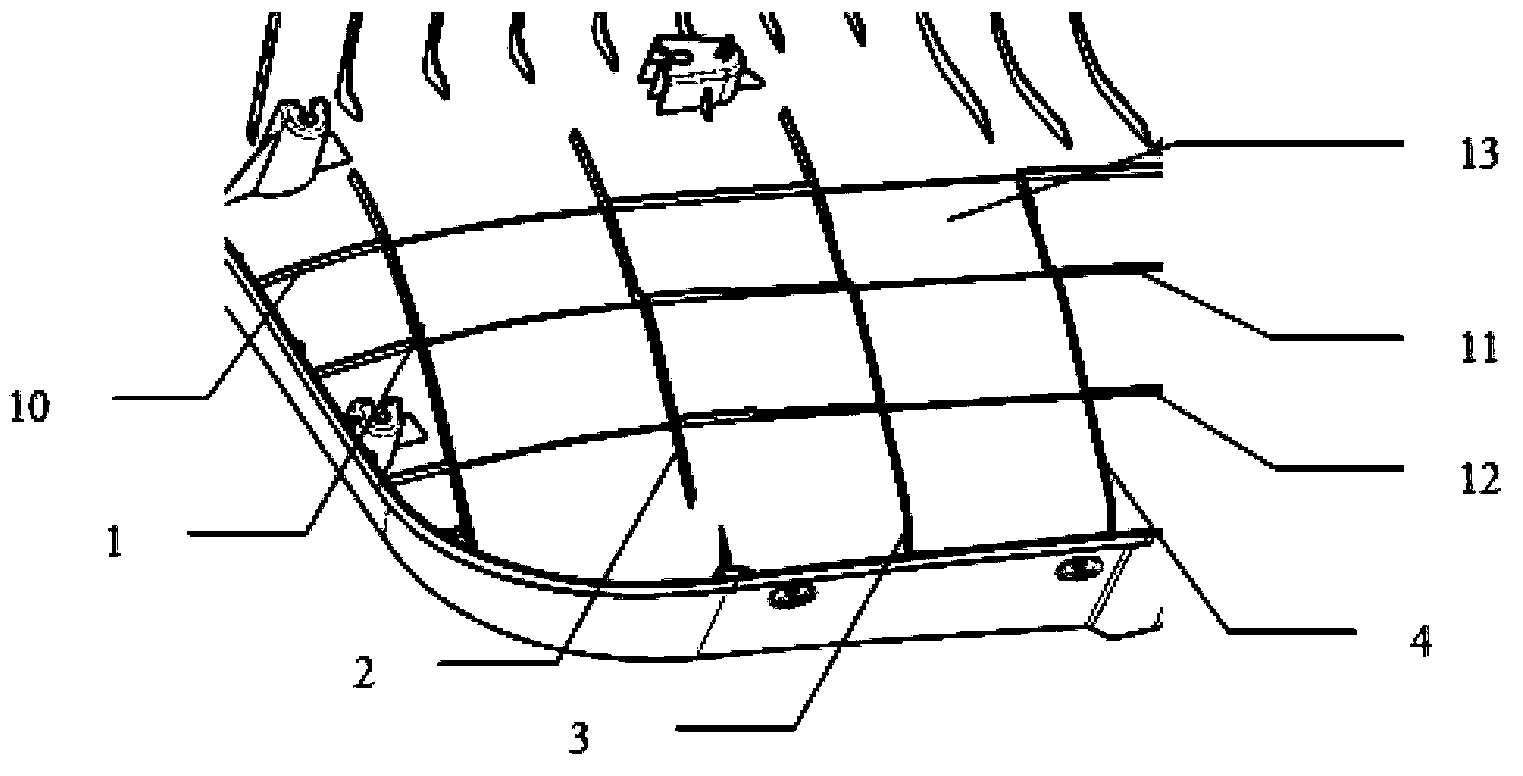

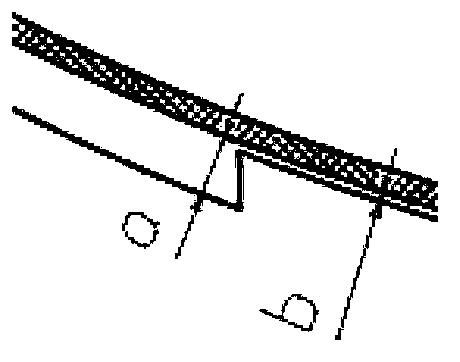

[0020] Such as figure 1 As shown, 13 is the main wall of the back door trim. Among them, 1, 2, 3, 4, 5, 6, 7, 8, and 9 are the first to ninth longitudinal ribs, 10, 11, and 12 are the first, second, and third transverse ribs, and the transverse ribs and The longitudinal ribs form a criss-cross connection rib design. On the basis of the original design, the present invention keeps the design of the original longitudinal rib position unchanged, reduces the heights of the three transverse ribs 10, 11 and 12 between the longitudinal rib 1 and the longitudinal rib 2; reduces the longitudinal rib 3 and the longitudinal rib The height of the three transverse ribs 10, 11 and 12 between the ribs 4; the height of the three transverse ribs 10, 11 and 12 between the longitudinal ribs 6 and 7; the height of the longitudinal ribs 8 and 9 The height of the three transvers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com