Engine cylinder sleeve puller

An engine cylinder and puller technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of difficulty in taking out the cylinder liner, damage to the fixed shoulder, etc., and achieves the effects of convenient application, flexible use and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

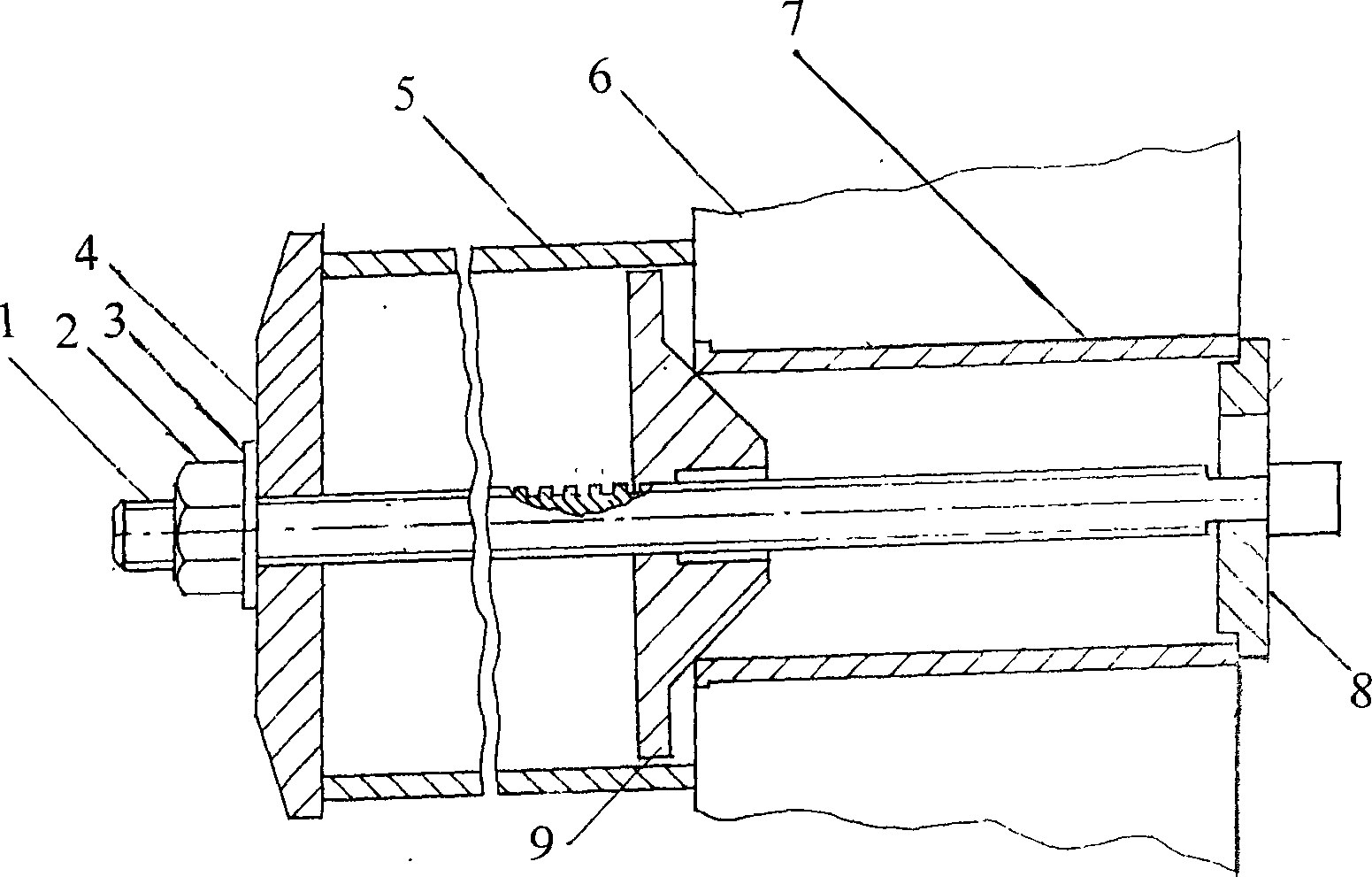

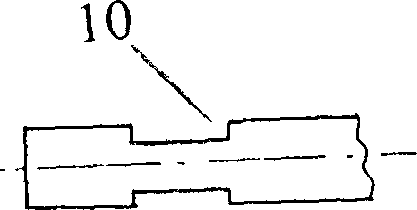

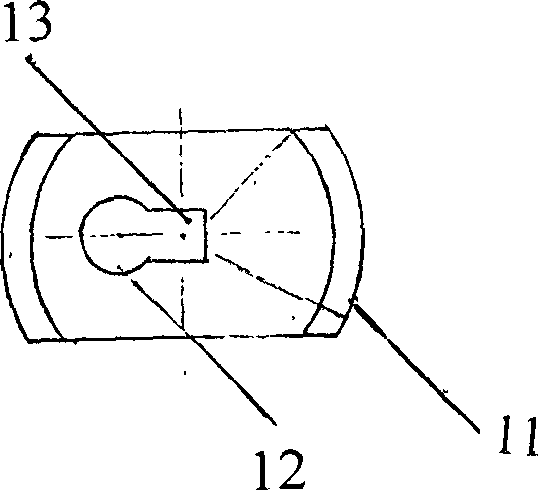

[0013] exist figure 1 Among them, the screw rod (1) adopts square teeth or canine threads, and the lower end is turned into an I-shaped rod head (10), and the pull plate (8) is a flanged pull head (11) that can pass through the cylinder hole, namely Long outer arc shoulder shape. When in use, the screw rod (1) must first be inserted into the round hole (12) on the side of the pull plate (8), and then introduced into the center strip screw hole (13), and then it will be firmly stuck; the center cone (9) It plays the role of central positioning and guiding; the bushing (5) is a discarded old cylinder liner, but its size and length must be larger than the replaced cylinder liner (7). When there is no old cylinder liner, three equal-length steel circles can be used Strips and wooden lining squares are used to form a 120° angle evenly distributed on the circumference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com