Dithizone grafted chelating gel, preparation method thereof and method for treating mercury-containing wastewater

A dithizone, chelating technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problem of unsatisfactory adsorption selectivity, and achieve enhanced adsorption selectivity and The effect of adsorption efficiency, efficient removal, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

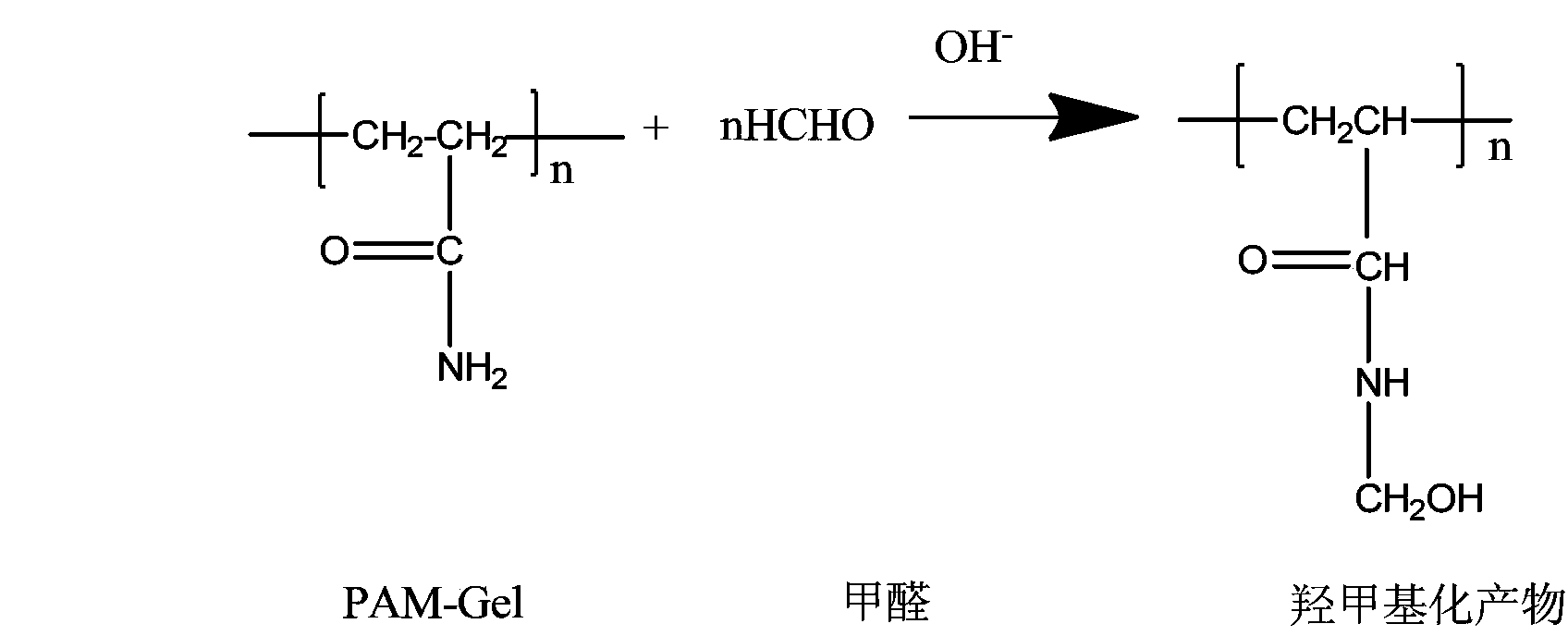

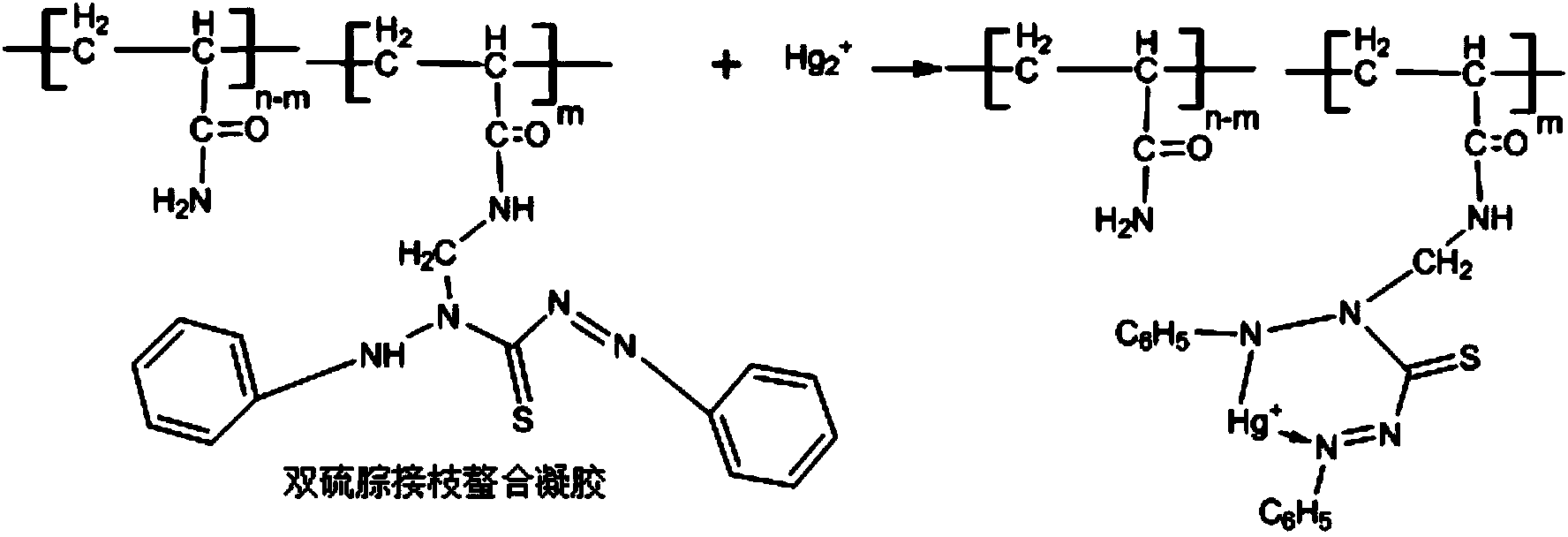

[0024] Weigh 1.5 parts of polyacrylamide gel and dissolve it in 95.6 parts of distilled water, adjust the pH to 9 with a 10% NaOH solution, transfer it into a three-necked flask equipped with a condenser tube and a dropping funnel, and add to the three-necked flask Add 2.8 parts of formaldehyde solution to the bottle, then dropwise add 0.1 part of 2g / L dithizone solution to the bottle, react in a water bath at 24°C for 120min, separate the product, and dry to obtain dithizone grafted chelate gel.

Embodiment 2

[0026] Weigh 2.0 parts of polyacrylamide gel, dissolve and mix it in 94.5 parts of distilled water, adjust the pH to 9 with a pH regulator 10% NaOH solution, and transfer it into a three-necked flask equipped with a condenser and a dropping funnel. Add 3.4 parts of formaldehyde solution to the above system, and then dropwise add 0.1 part of 2g / L dithizone solution to the bottle, react in a water bath at 36°C for 120min, separate the product, and dry it to obtain dithizone. Branch chelating gel.

Embodiment 3

[0028] Weigh 1.0 part of polyacrylamide gel, dissolve and mix it in 96.8 parts of distilled water, adjust the pH to 9 with a pH regulator 10% NaOH solution, and transfer it into a three-neck flask equipped with a condenser and a dropping funnel. Add 2.0 parts of formaldehyde solution to the above system, and then dropwise add 0.2 parts of 2g / L dithizone solution to the bottle, react in a water bath at 24°C for 180min, separate the product, and dry it to obtain dithizone. Branch chelating gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com