Modular coolant jacket for rolling mills and rolling mill laying head comprising such a coolant jacket

A coolant jacket and coolant technology, applied in the field of coolant jackets, can solve the problems of laborious replacement of water jackets, time-consuming separation of pinch roller components, etc., and achieve the effects of cost saving, reducing the types of spare parts, and reducing production downtime.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

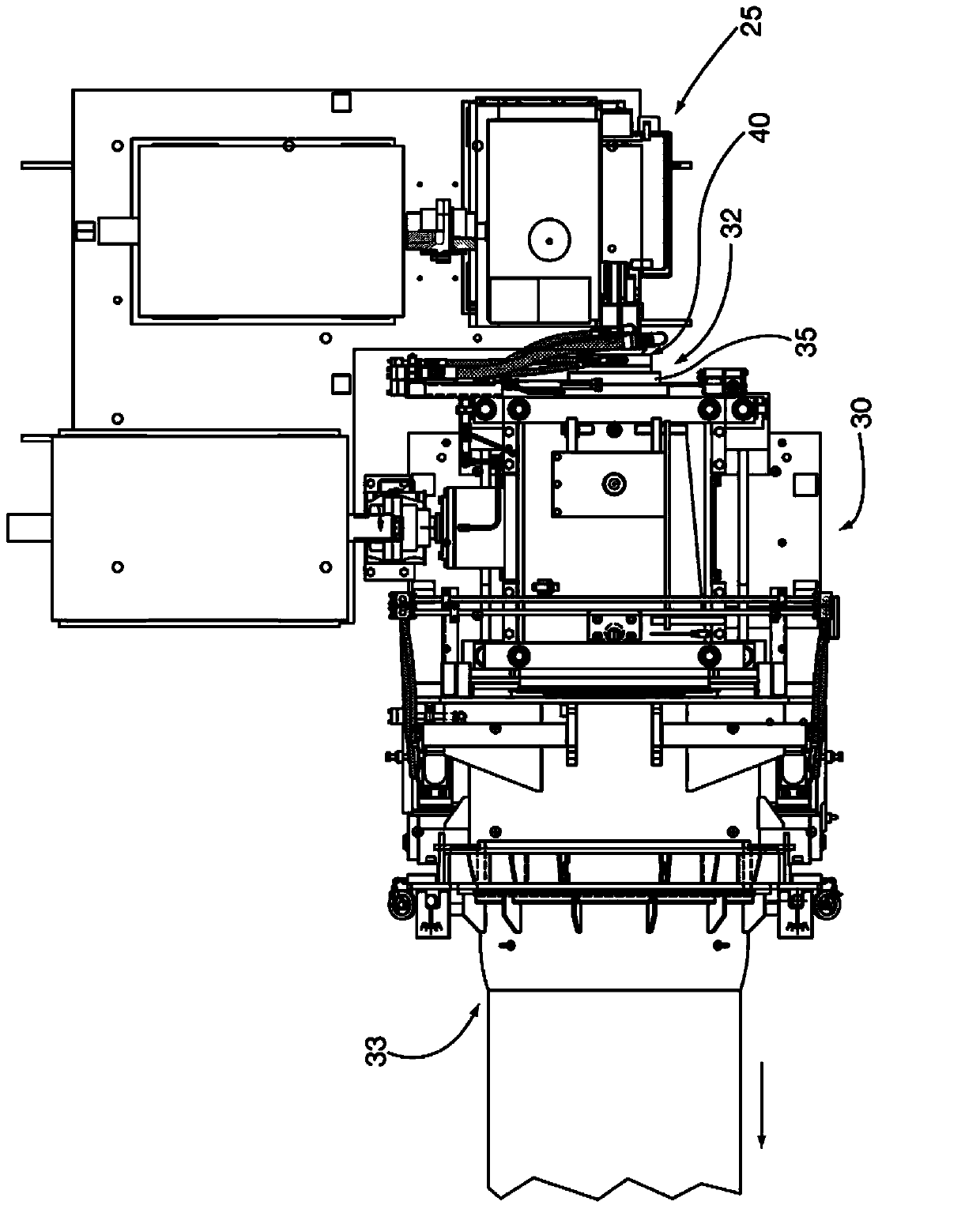

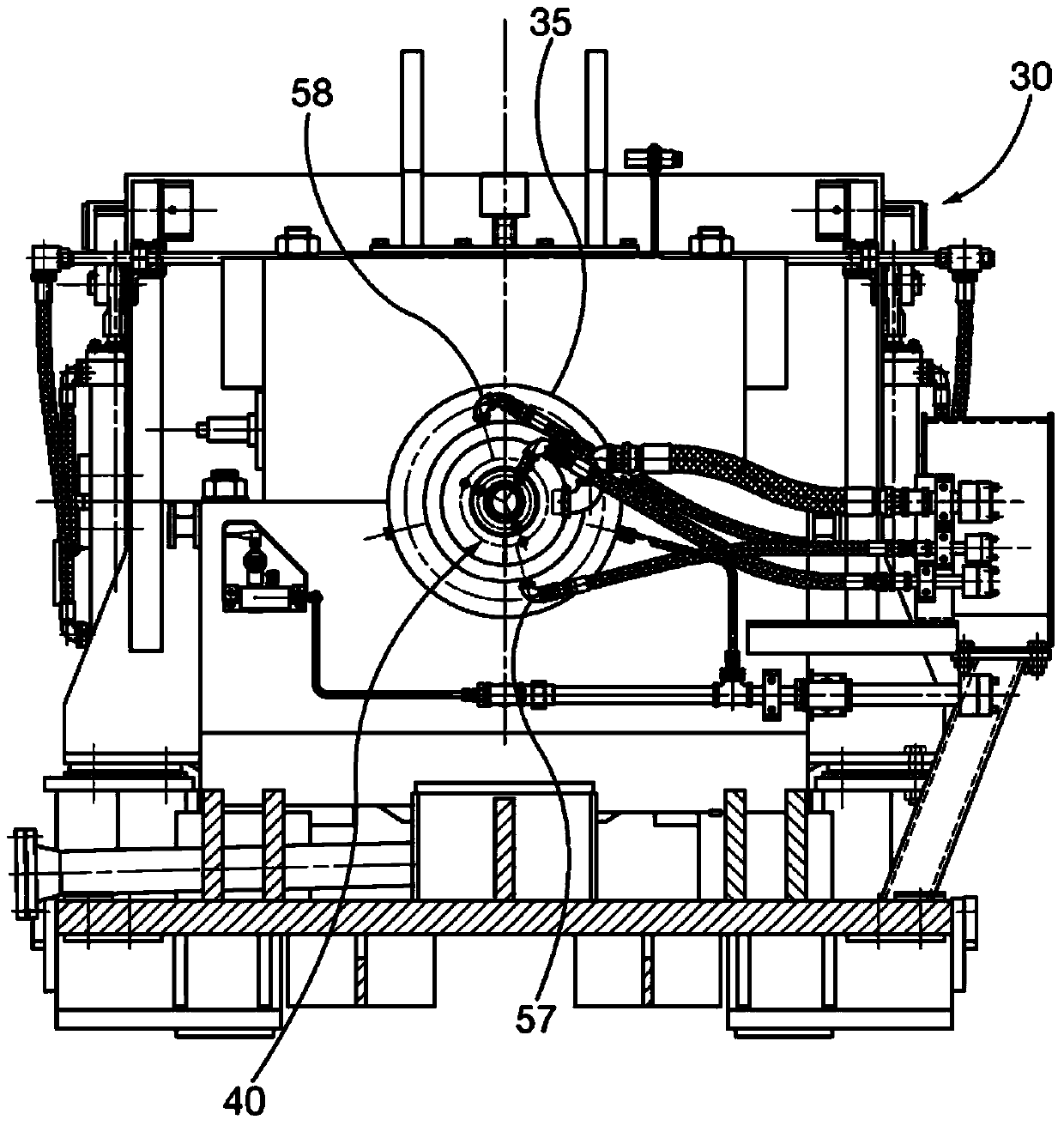

[0025]After considering the following description, it will be apparent to those of ordinary skill in the art that the teachings of the present invention can be readily applied to rolling mill coolant jackets, including water jackets. The modular coolant jacket of the present invention has a coolant tube barrel portion and a selectively detachable outer flange portion. The separation of the larger diameter outer flange portion from the barrel tube facilitates the separation of the barrel portion in radially confined spaces - such as within elongated / slender material feed paths, between pinch rolls and laying heads. Axially oriented insertion and removal in space. The modular construction also facilitates reuse of the outer flange portion and replacement of only the worn / worn cartridge body.

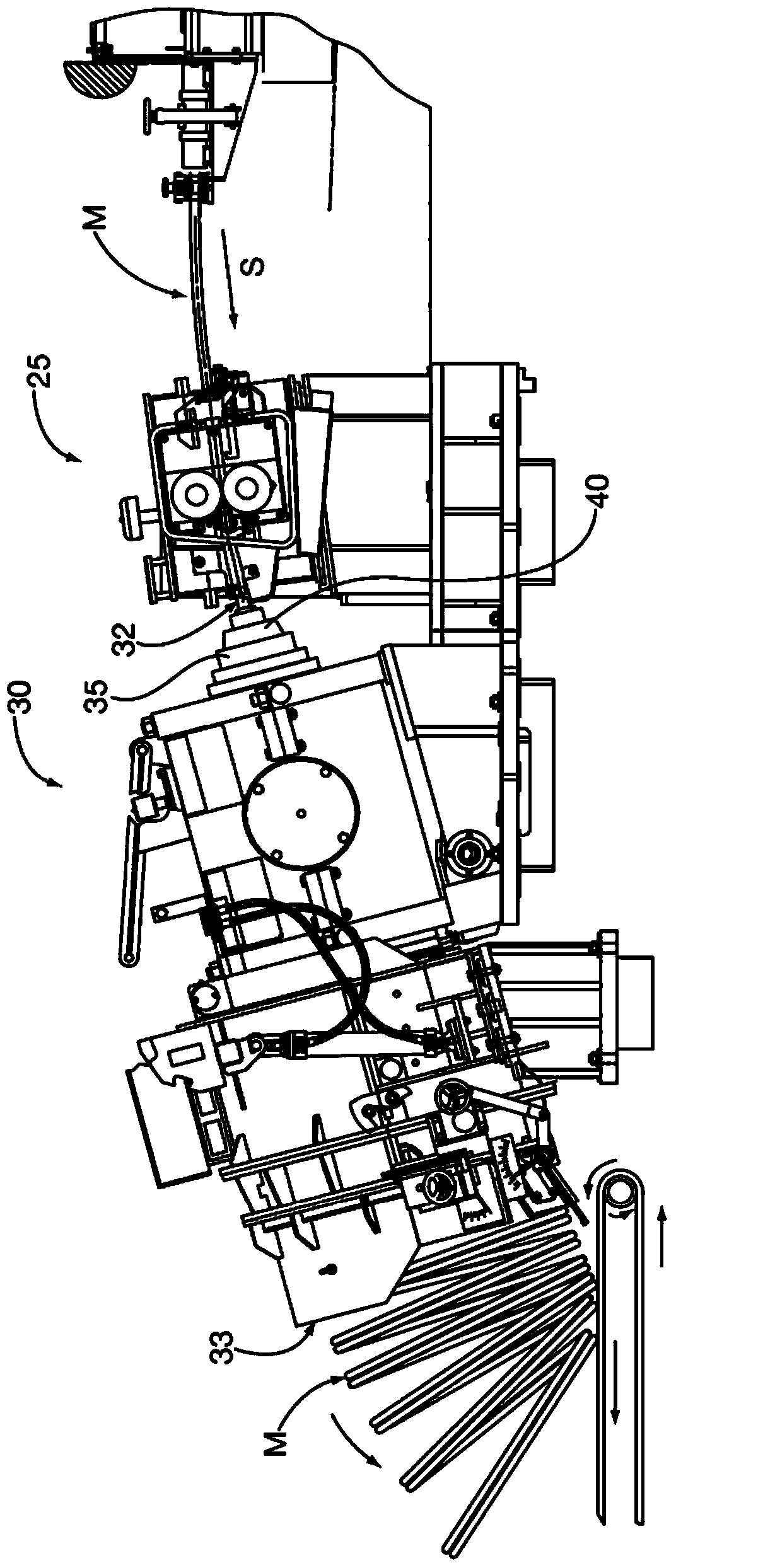

[0026] Figure 1 to Figure 4 A rolling mill according to an exemplary embodiment of the invention is shown in and has a pinch roll assembly 25 feeding elongated material M at a speed S i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com