N type joint

A type and connector technology, which is applied in the field of quick connection with leakage cables, can solve the problems of time-consuming and labor-intensive, large dispersion of electrical performance VSWR, large deviation of hollowing size, etc., to achieve fast assembly and discrete electrical performance small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings.

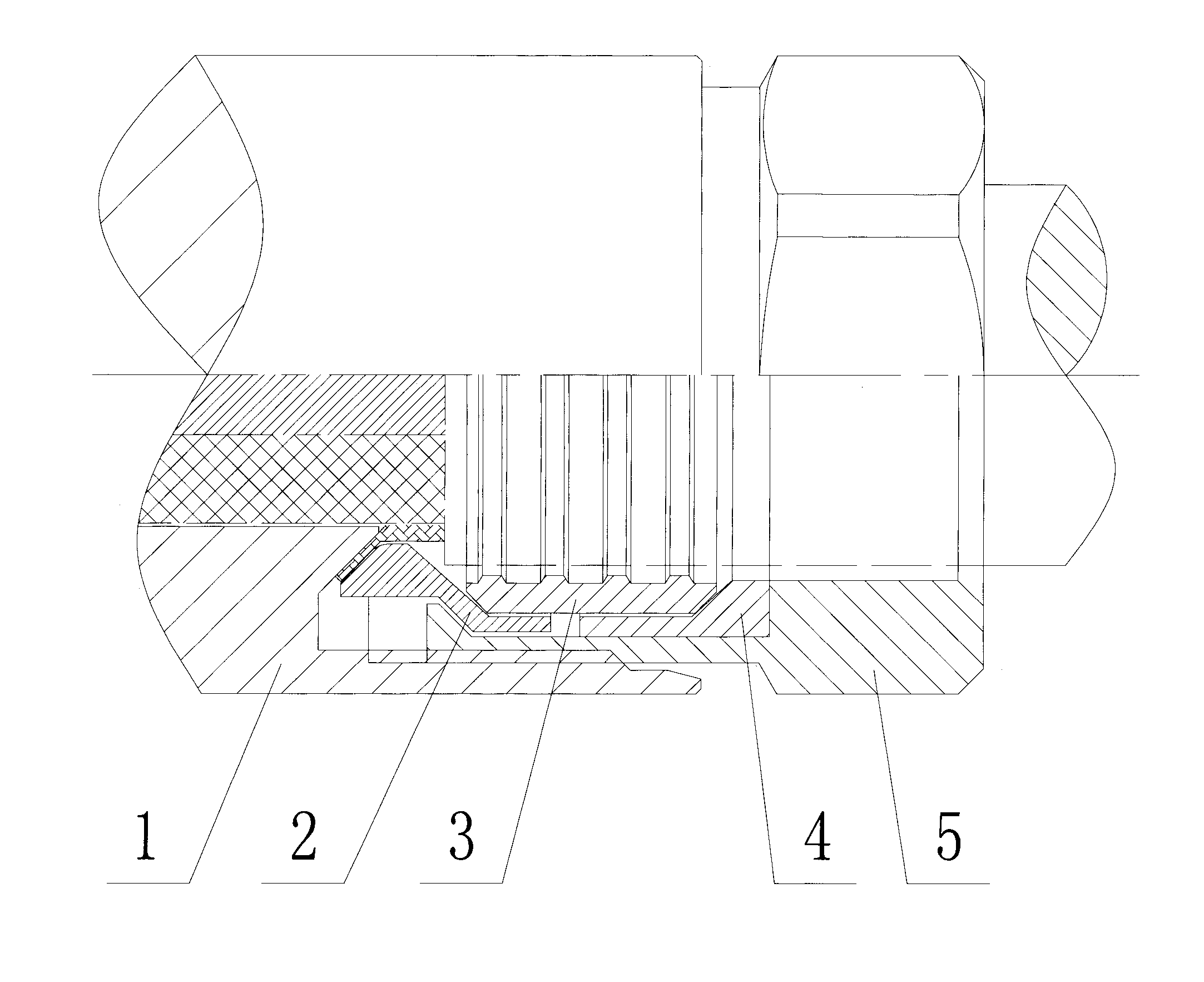

[0009] As shown in the figure, an N-type connector includes a connector body 1 and a connector body 2 5, and the two are threaded. V"-shaped bushings 2, 4, the clamp 3 and the bushings 2, 4 are located in the inner space formed after the joint body 1 is connected with the joint body 2 5, and the bushes 2, 4 are respectively covered At both ends of the clamp 3, the inner tooth profile of the clamp 3 coincides with the outer profile of the outer conductor of the leakage cable to be connected.

[0010] When the N-type connector of the present invention is connected to the leaking cable, it is only necessary to use a blade to peel off the sheath at the end of the leaking cable, omitting the process of hollowing out the insulating medium. During the screwing process of the first joint body and the second joint body, the bushing Axial displacement extrusion with internal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com