Oil pipe joint

A technology for oil pipe joints and pipelines, applied in the hydraulic field, can solve problems such as danger and metal leakage, and achieve the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further description will be given below in conjunction with the accompanying drawings

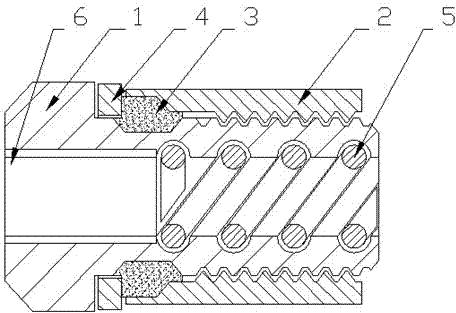

[0015] An oil pipe joint, comprising a joint main body 1 and a locking sleeve 2, the joint main body 1 is a hollow cylinder, an equipment connection part 6 is provided at one end of the hollow cylinder in the axial direction, and a pipe is provided at the other axial end of the hollow cylinder connecting part;

[0016] The outer wall of the hollow cylinder of the pipe connection part is provided with threads, and the locking sleeve 2 is sleeved on the outer wall of the hollow body through threads. The inner wall of the hollow body of the pipe connection part is provided with a spiral groove, and a coil spring 5 is embedded in the spiral groove. A plurality of linear grooves are arranged on the wall surface of the hollow main body of the connection part;

[0017] The equipment connection part 6 is provided with threads connected with the equipment;

[0018] The end of the locking sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com