Safe and efficient mud drilling jet mill bit for horizontal wells

A technology for grinding drill bits and horizontal wells, which is applied to drill bits, drilling equipment, wellbore/well components, etc. It can solve problems such as reducing the ROP, and achieve the effects of increasing the ROP, reducing the final settlement velocity, and avoiding repeated crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

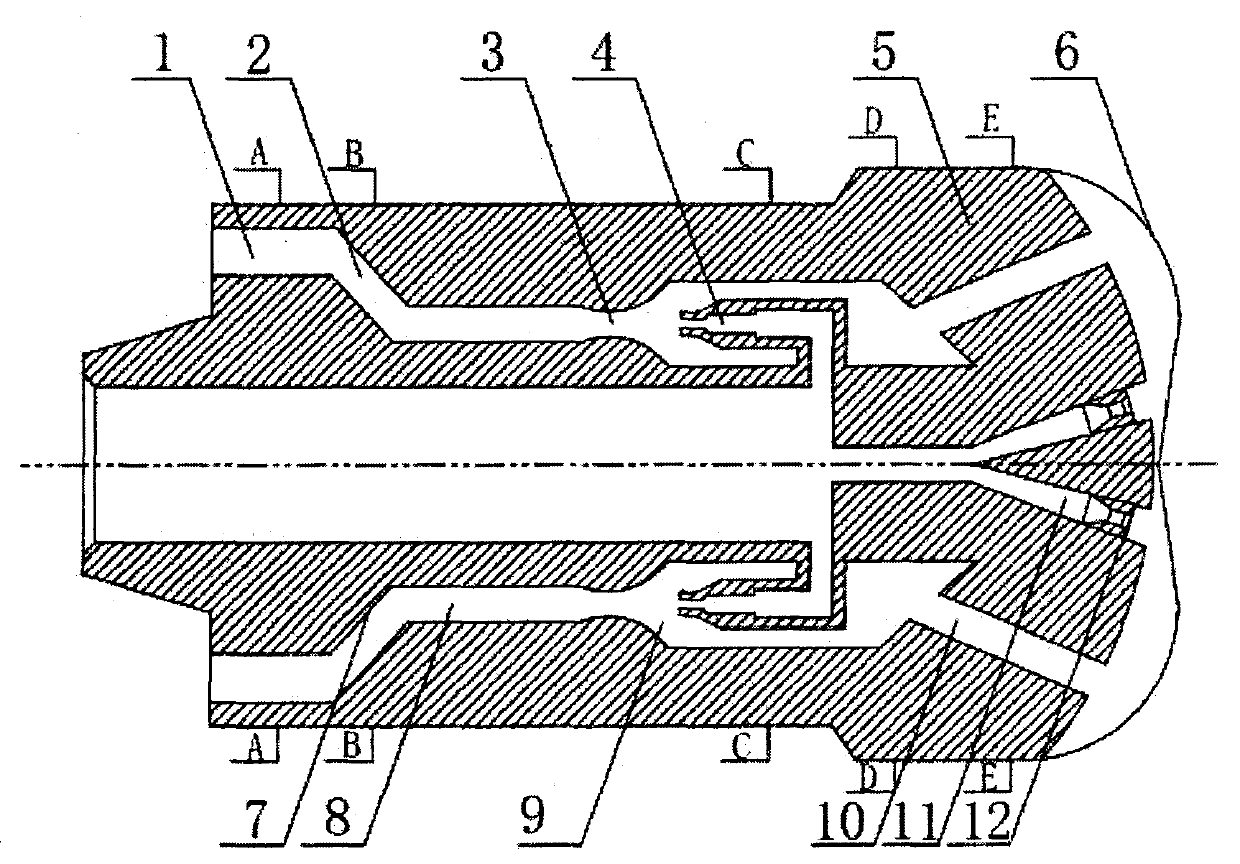

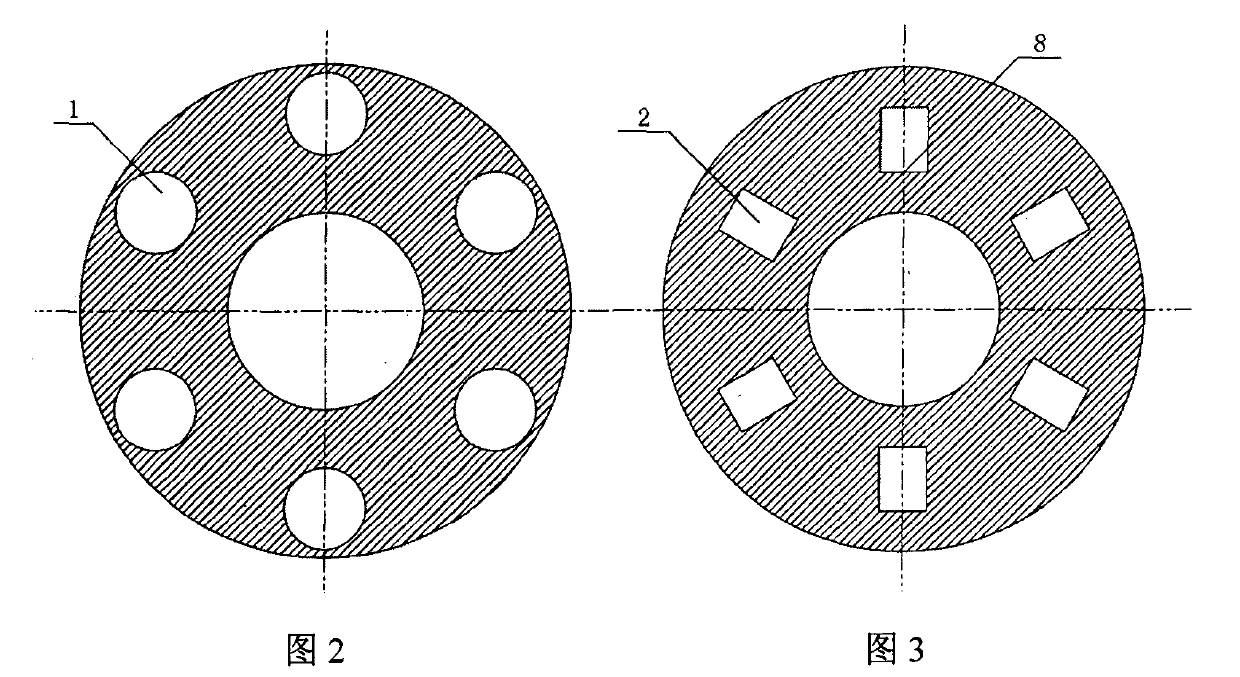

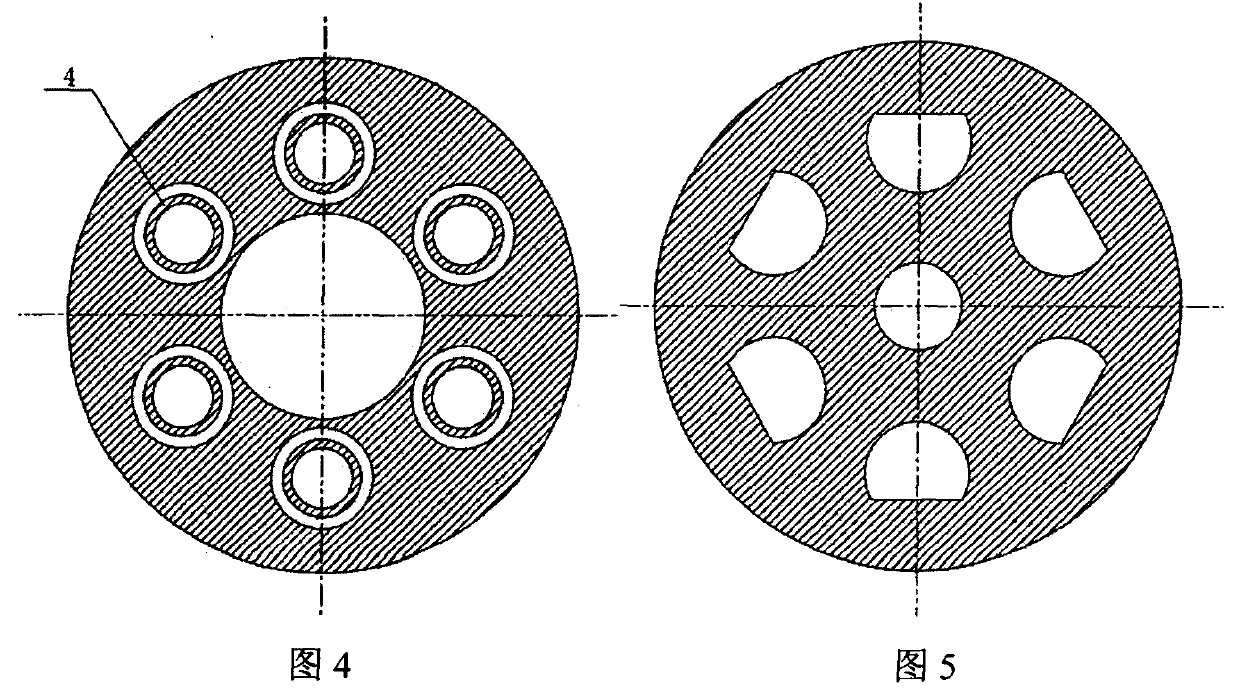

[0030] Such as figure 1 As shown, a jet mill bit for safe and efficient mud drilling in horizontal wells, including: 1. bypass, 2. crushing chamber, 3. throat, 4. reverse self-vibrating cavitation jet nozzle, 5. PDC bit body , 6. Drill bit blade, 7. Crushed target body, 8. Dissociation acceleration tube, 9. Mixing chamber, 10. Cuttings suction pipe, 11. Bottom cuttings mixing and cleaning flow channel, 12. Drill bit water eye nozzle . In summary, there are two main parts: the sand pump at the bottom of the drill bit, and the jet mill.

[0031] During the drilling process, the high-pressure drilling fluid enters through the main channel, and a part of the drilling fluid is ejected from the reverse self-vibrating cavitation jet nozzle 4 to form a high-speed cavitation pulse jet, which generates negative pressure in the mixing chamber 9, The negative pressure sucks the bottom hole fluid and cuttings through the cuttings suction pipe 10, thereby reducing the pressure difference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com