Three-dimensional movable compacted sand pile forming system in centrifugal test

A technology of compacted sand pile and centrifugal test, which is applied in the test of foundation structure, sheet pile wall, building, etc., can solve problems such as insufficient understanding and application constraints of compacted sand pile composite foundation, and achieve fast piling speed and production Convenience and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

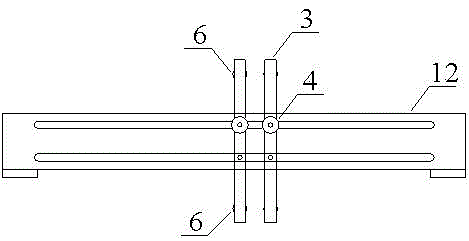

[0021] The device consists of a sleeve 1 and a piston 2 required for piling, a set of pulleys 6 located on the left and right sides of the sleeve to ensure that the sand pile is vertical, a chute 12 for the pulley to move above the model box, and a hand-operated piling weight composition.

[0022] Sleeve 1 is an aluminum hollow cylinder with a wall thickness of 2 mm. The length and outer diameter must be determined according to the length and diameter of the target sand pile. small. Piston 2 is a cylindrical iron long rod with a diameter of 8mm. The diameter of the 10mm at the bottom end of the rod is expanded to be slightly smaller than the inner diameter of the sleeve, which is used to hit the sand downwards, and the diameter of the 5mm at the top is enlarged to 30mm. Accept the downward impact force of the piling weight.

[0023] The pulley assemblies positioned at both sides of the sleeve 1 to ensure the verticality of the sand piles include four pulleys 6, two on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com