Automatic cable winding conveying tension adjusting device

An automatic adjustment and winding technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of reducing the service life of cables, affecting the quality of cable winding, and damaging the cable insulation layer, etc., to achieve Guaranteed quality, simple structure, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

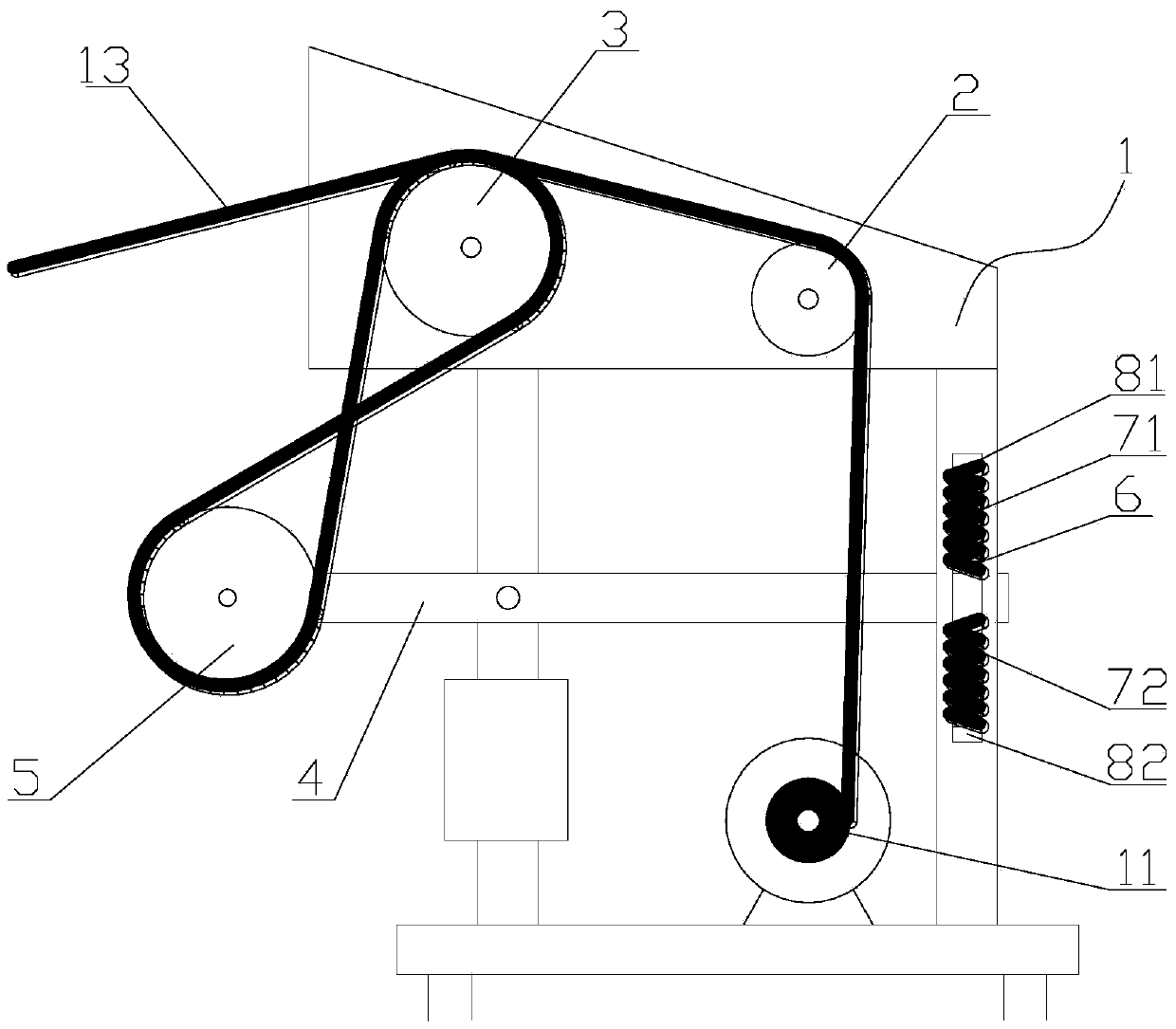

[0012] like figure 1 as shown, figure 1 It is a structural schematic diagram of an automatic tension adjustment device for cable winding proposed by the present invention.

[0013] refer to figure 1 , a kind of conveying tension automatic adjustment device of cable winding that the present invention proposes, comprises: frame 1, wire wheel 2, fixed winding wheel 3, winding reel 11, pendulum bar 4, floating winding wheel 5, upper spring 71, lower spring 72, upper pressure sensor 81, lower pressure sensor 82, driving mechanism and control mechanism;

[0014] The winding reel 11 is arranged on the frame 1 bottom, and the cable 13 on the winding reel 11 passes through the wire reel 2, the fixed reel 3, the floating reel 5, the fixed reel 3 and output successively, the wire reel 2, The fixed reel 3 is arranged on the top of the frame 1, and the fixed reel 3 is driven by the driving mechanism on the frame 1, and the driving mechanism is connected with the control mechanism on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com