Full-automatic machine for cutting plates

A fully automatic and machine technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of incomplete cutting, single cutting products, unguaranteed product quality, etc., to avoid incomplete cutting, cutting Quick and smooth, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

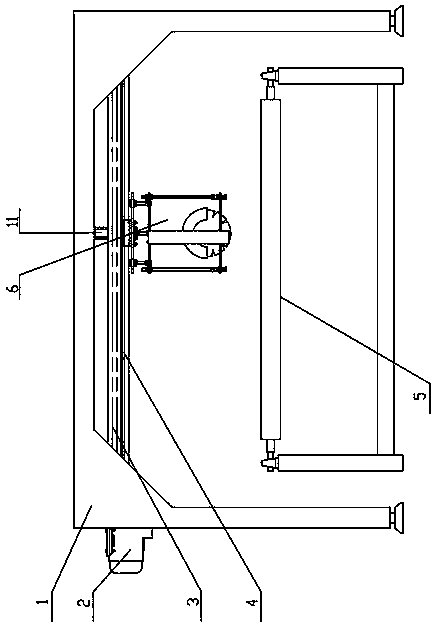

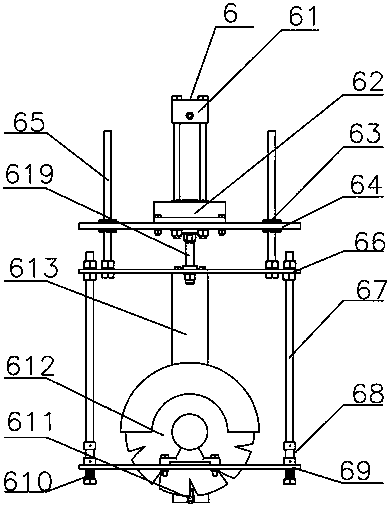

[0022] Such as figure 1 , figure 2 As shown, the present invention includes a fuselage 1 and a feed device 10, a cutting device 6, a detection adjustment device 11, and a conveyor belt 5 that are all arranged inside the fuselage 1. The fuselage 1 is a frame structure supported by four columns. The middle part of the top of the body 1 is provided with a guide bar 11 along the length direction, the feeding device 10 is arranged on the top of the body 1, the cutting device 6 is fixedly arranged at the lower end of the feeding device 10, and the detection adjustment device 11 is arranged on the cutting device 6 On, the conveyor belt 5 is set at the bottom of the fuselage 1, the sheet is placed on the conveyor belt 5, and the sheet is conveyed along one direction;

[0023] Feeding device 10 comprises transverse nut screw kinematic pair 3, longitudinal nut screw kinematic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com