Pressure limiting water-break water purifier

A pure water machine and water cut-off technology, applied in osmosis/dialysis water/sewage treatment, non-polluted water treatment, reverse osmosis, etc., can solve the problems of high failure rate, increase machine cost, increase power consumption, etc., and achieve low failure rate , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

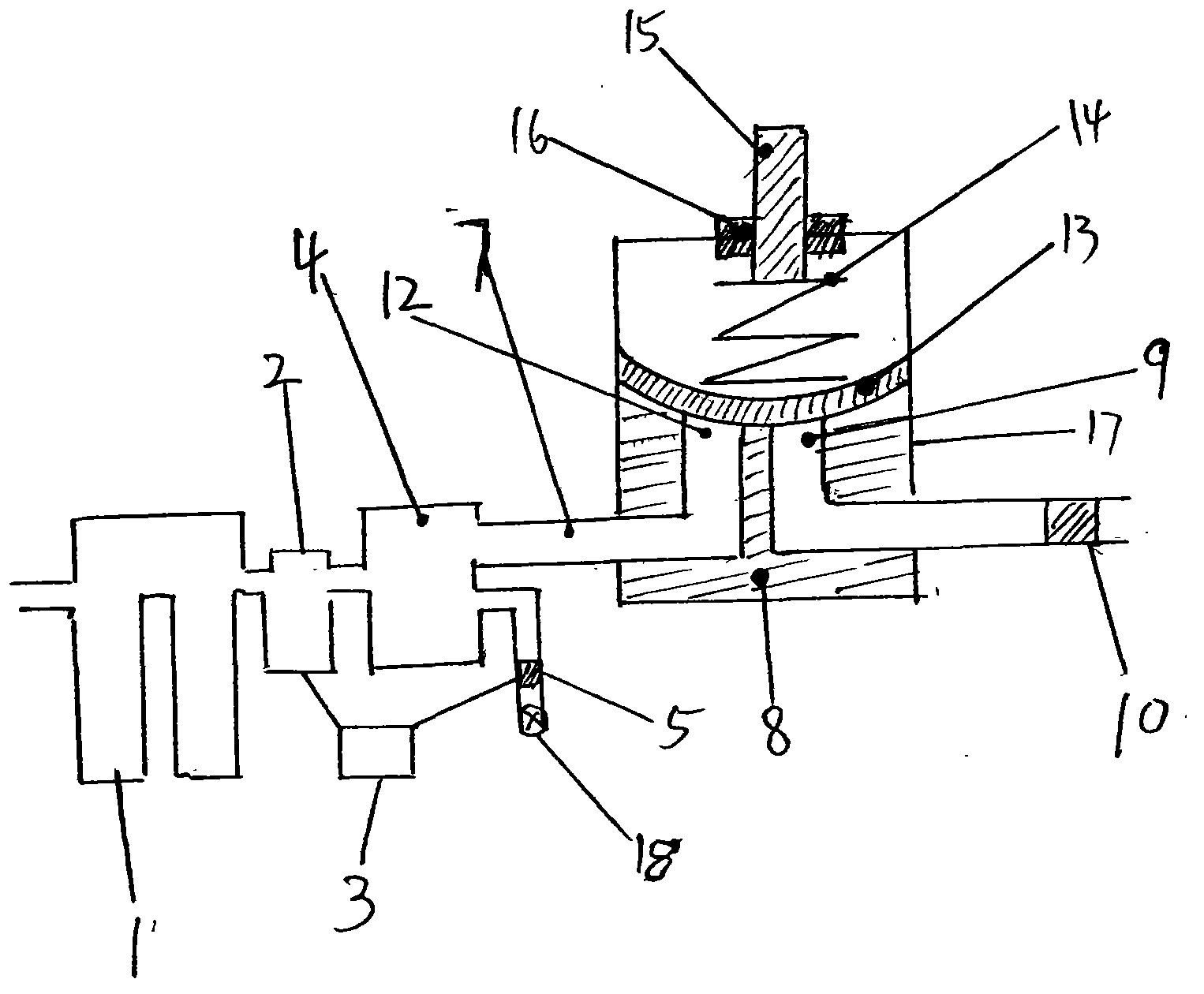

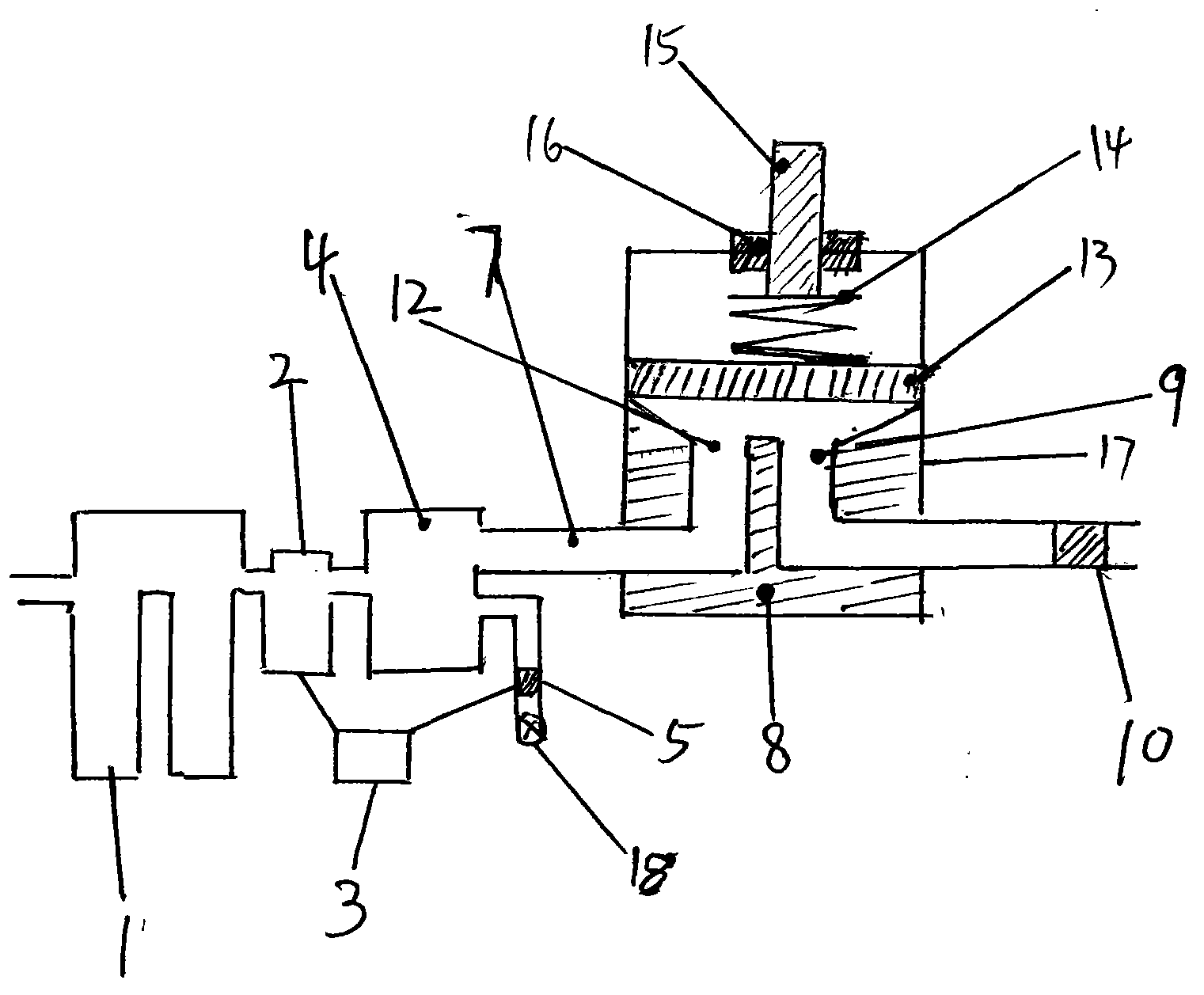

[0008] Below in conjunction with the accompanying drawings further illustrate the pressure limiting water cut off pure water machine of the present invention:

[0009] figure 1 The pressure-limiting and water-cutting pure water machine of the present invention shown is composed of a primary filter group 1, a water pump 2, a power supply 3, an RO membrane group 4, a high-voltage switch 5, and a wastewater ratio of 10. The concentrated water outlet pipe 7 is connected to a wastewater ratio of 10, RO The concentrated water outlet pipe 7 connected to the membrane group 4 is connected with a concentrated water pressure limiting water shut-off valve 8 . The water inlet 12 and the water outlet 9 of the concentrated water pressure limiting water cutoff valve 8 are in the pressure limiting water cutoff valve housing 17, the water inlet 12 and the water outlet 9 have a water cutoff diaphragm 13, and the water cutoff diaphragm 13 has a pressure spring 14 on it. The spring 14 is topped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com