Automatic filter capable of controlling slurry density and application method thereof

A slurry concentration and filter technology, which is applied in the field of solid-liquid separation and filtration devices, can solve the problems of high labor intensity of loading and unloading plates, low production efficiency, and difficulty in controlling the moisture content of the filter cake. , the effect of less auxiliary equipment and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

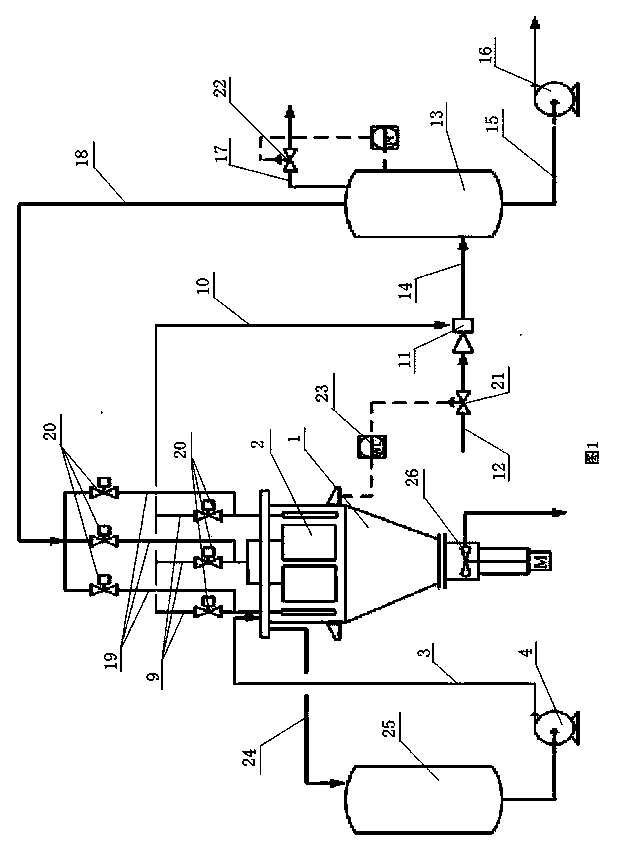

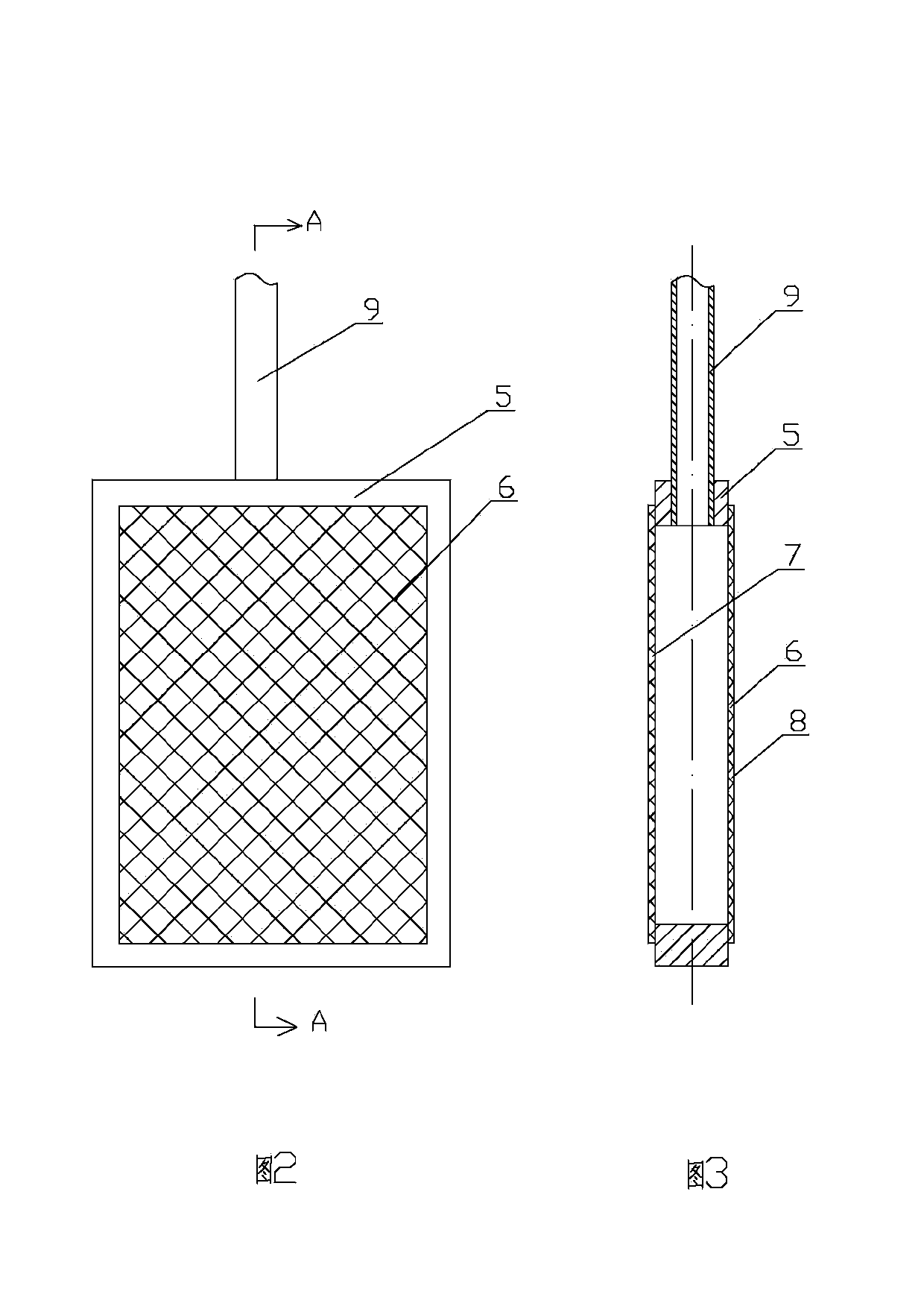

[0019] Embodiment 1, as attached figure 1 , 2 , 3, the automatic filter that can control the concentration of the slurry includes a filter tank 1, a filter rack 2, a liquid outlet main pipe 10, an air injector 11, a filtrate tank 13 and a blowback main pipe 18; the filter tank 1 The upper end of the filter tank 1 is fixedly equipped with a feed pipe 3, the feed pipe 3 is fixedly installed with a slurry pump 4, and at least three filter rackets 2 are fixedly installed in the upper inner cavity of the filter tank body 1 and are divided into three groups. Each filter racket 2 all comprises filter frame 5, front filter screen 6 and rear filter screen 7, front filter screen 6 and rear filter screen 7 are respectively sealed and fixedly installed on the front and rear sides of filter frame 5, filter frame 5, front filter screen 6 and the rear filter screen 7 jointly form a filter chamber 8, and there are installation holes on the filter frame 5 corresponding to the filter chamb...

Embodiment 2

[0021] Embodiment 2, as a preference of the above embodiment, according to needs, the number of filter beats 2 is a multiple of 3, and is divided into three groups on average. Divide the filter beat 2 into three groups on average, which can better control the timing. Among the three groups, one group is back blowing, and the other two groups are filtering. If one group or one filter beat 2 fails, it will not affect other groups. The normal work of filter beat 2 or other filter beat 2; on average, three groups work at the same time, which has a better filtering effect and makes the filter continuous.

Embodiment 3

[0022] Embodiment 3, as the preferred embodiment of the above, as attached figure 1 As shown, a clear liquid discharge pipe 24 is fixedly installed on the upper end of the filter tank body 1 . The filtered clear liquid and air are sent to the filtrate tank 13 through the air injector 11, and the excess clear liquid is discharged by the clear liquid discharge pipe 24.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com