self-cleaning insecticidal lamp

An insecticidal lamp and self-cleaning technology, which is applied in the device, application, animal husbandry and other directions of catching or killing insects, can solve the problems of inability to clean up, the insecticidal lamp cannot work, the insecticidal lamp cannot be used, etc., and achieves high performance. Reliable, development-promoting, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the drawings and specific embodiments.

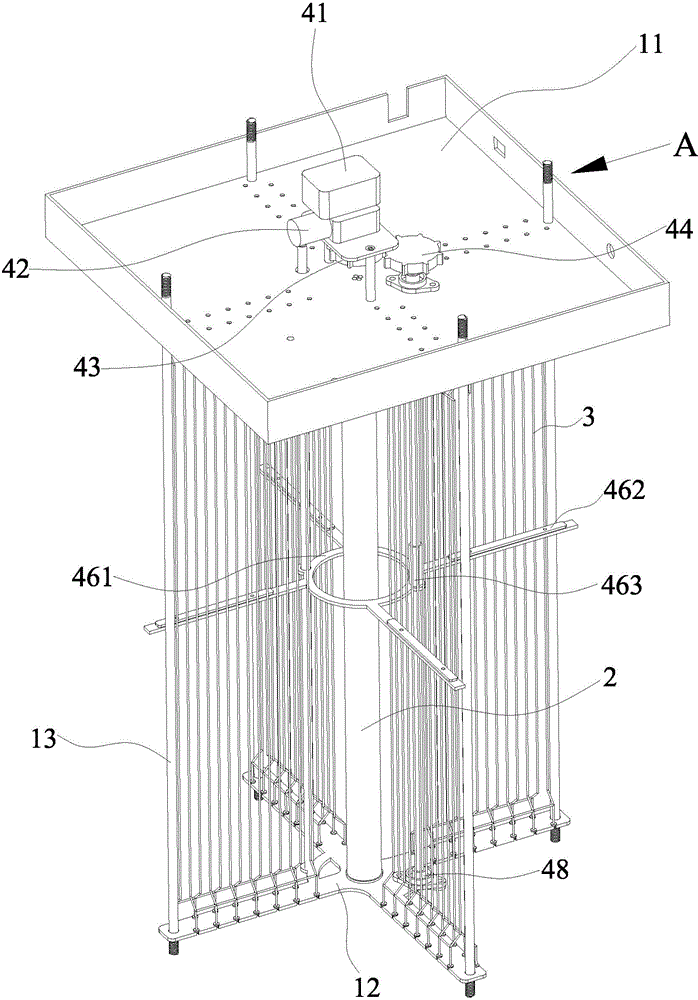

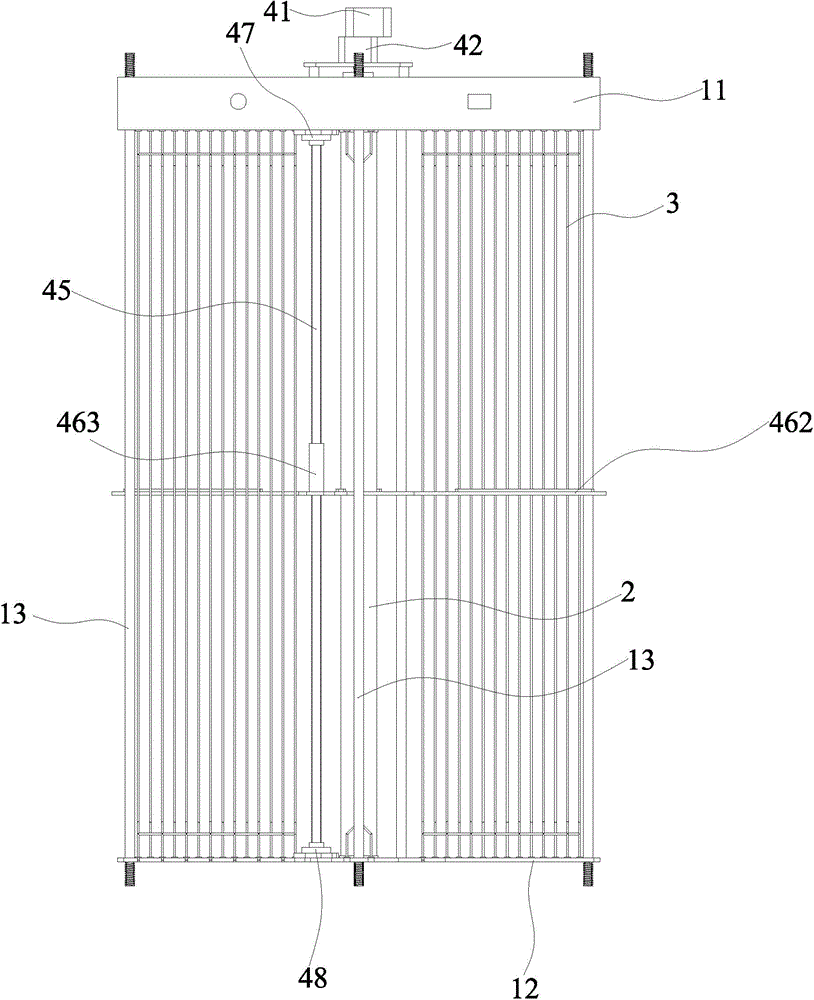

[0015] like figure 1 and figure 2 As shown, the self-cleaning insecticidal lamp includes a bracket, an insect trap lamp 2, an electric shock net 3 and a cleaning device, the bracket includes a top plate 11, a base 12 and four pillars 13, and the top plate 11 and the base 12 are arranged in parallel , top plate 11 and base 12 center each have a blind hole, top plate 11 is evenly distributed around four threaded holes, the base 12 is cross-shaped, base 12 four ends each have a threaded hole, column 13 upper end and top plate The threaded holes of 11 are threaded, the lower end of the column 13 is threaded with the threaded holes of the base 12, and the column 13 is perpendicular to the top plate 11 and the base 12, so that the top plate 11 and the base 12 are connected; the two ends of the insect trap lamp 2 Installed respectively in the blind holes in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com