Improved braking for rail vehicles

A technology for rail vehicles and rails, applied in the field of control devices for braking equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

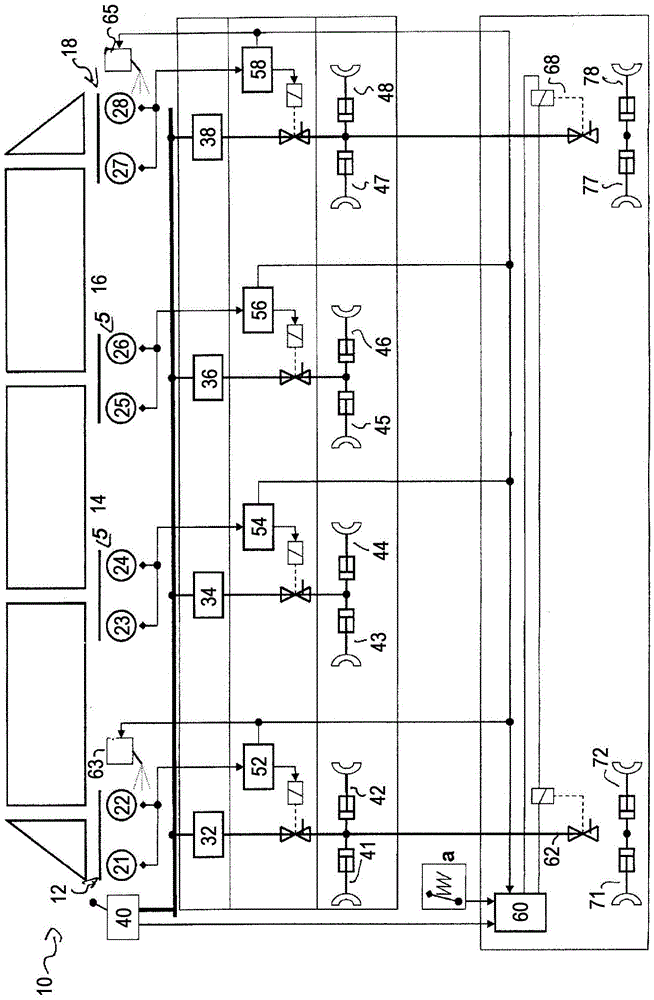

[0019] figure 1 The rail vehicle 10 is schematically shown. The rail vehicle 10 has a plurality of carriages, and these carriages include a first bogie 12, a second bogie 14, a third bogie 16 and a fourth bogie 18. Axles 21 and 22 are arranged on the first bogie 12. Axles 23, 24 are arranged on the second bogie 14, while axles 25, 26 are arranged on the bogie 16 and axles 27, 28 are arranged on the bogie 18. The pressure-acting brake devices are respectively assigned to the axles of the bogie, and the brake pressure is provided to the brake devices through a common control valve. Therefore the first control valve 32 is assigned to the first bogie 12, the second control valve 34 is assigned to the second bogie 14, the third control valve 36 is assigned to the third bogie 16 and the fourth control valve 38 is assigned to the fourth steering frame. The control valves 32, 34, 36, 38 are connected to the main pressure line, which supplies control pressure to the control valves 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com