Optical fiber unit box and optical fiber unit box wiring method

A wiring method and unit box technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of influence interference, easy operation errors, inconvenient operation, etc., to achieve the effect of clear wiring, avoiding adverse effects, and capacity expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

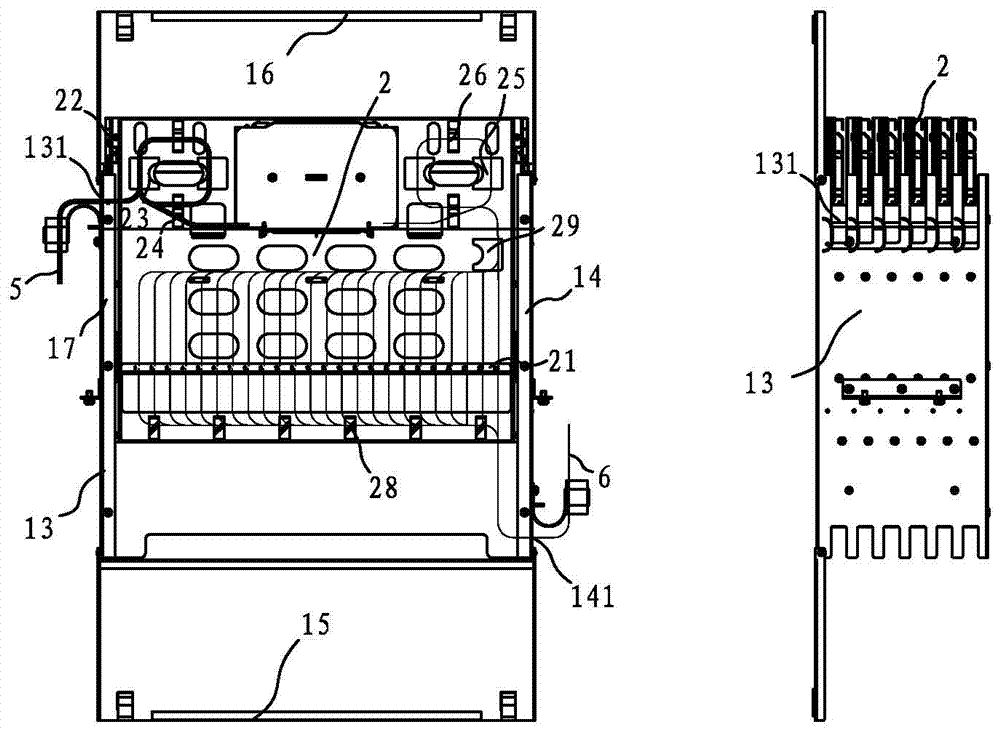

[0049] The existing optical fiber unit box is generally operated on one side. The optical fiber operation surface of the optical cable and the jumper fiber operation surface are all concentrated in the front of the optical fiber unit box. Sharing one operation surface makes it easy to interfere with each other during operation, and the operation is prone to errors. The limitation of the operation surface also limits the capacity of the optical fiber unit box, making it impossible to further expand the capacity. In order to solve the lack of a fiber jumper management in the prior art, which is simple in management, clear in wiring, and convenient in operation, it is suitable for the fiber unit box and the wiring method of the fiber unit box for optical fibers with small curvature radius, which can make the fiber unit box even in the case of large capacity. The wiring is still clear, and it is not easy to cause operational errors.

[0050] The optical fiber unit box of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com