A composite material rudder surface load loading device

A composite material and loading device technology, which is used in measuring devices, analyzing materials, and testing the strength of materials by applying a stable torsion force, can solve the problems of structural damage of the rudder surface, inability to apply, and the test cannot be carried out normally, so as to achieve uniform loading, Avoid centralized loading effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

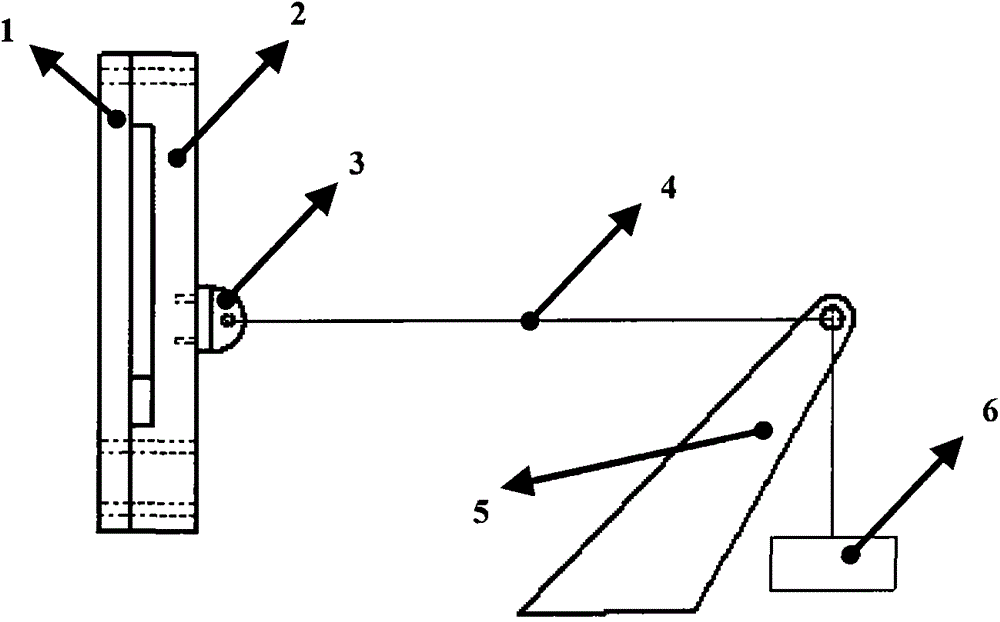

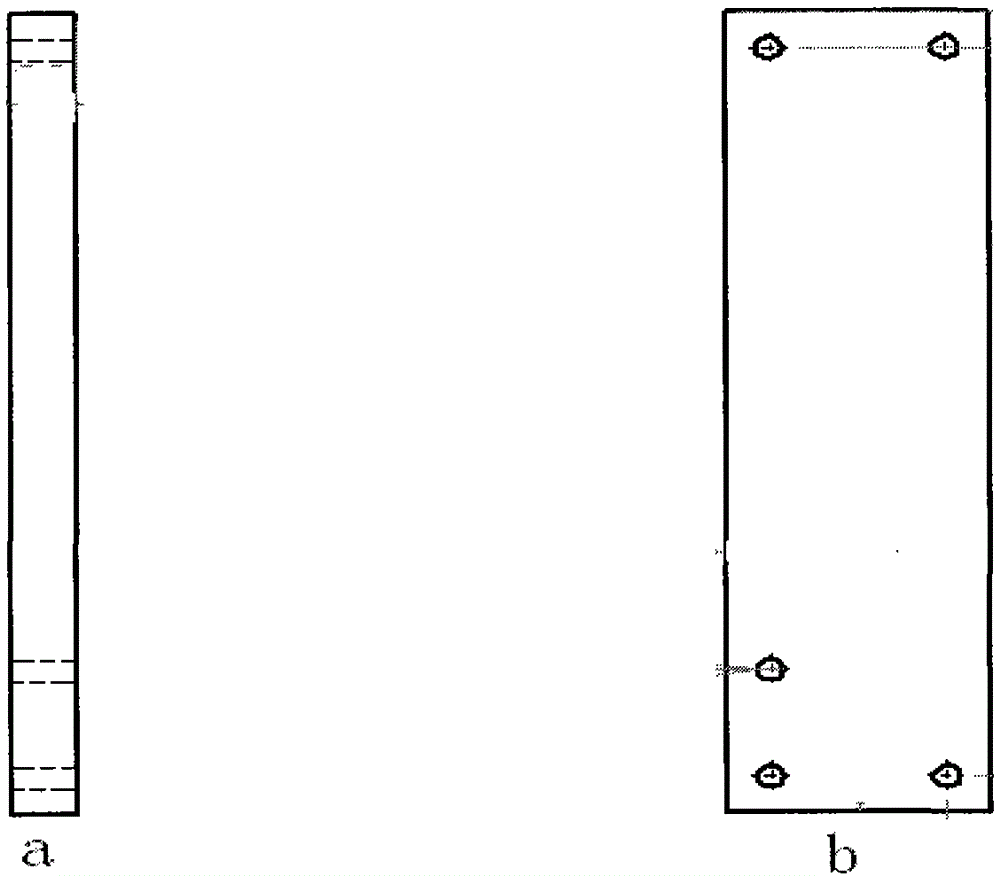

[0028] The present invention realizes the joint loading of the rudder surface bending moment and torque by designing a set of rudder surface loading fixtures, such as Figure 1 ~ Figure 4 shown.

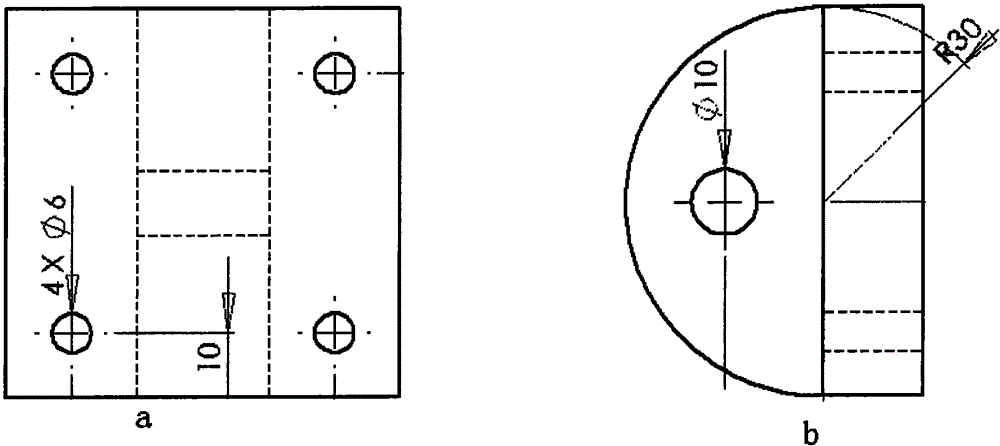

[0029] Install two loading fixtures on both sides of the air rudder. The inner surface of the two fixtures is consistent with the outer surface of the air rudder, so as to realize the close fit between the fixture and the air rudder, ensure uniform loading, and avoid the shaking of the air rudder. The two clamps are fixed to each other.

[0030] One side of any fixture is fixed on the adapter block, and the position of the adapter block is located at the pressure center of the rudder surface, which can accurately simulate the bending moment and torque on the rudder surface.

[0031] One end of the steel rope is fixed to the adapter block, and the other end passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com