Recyclable ground stress testing device

A test device and recovery device technology, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of test failure, no stress transfer point, and only one-time use, so as to achieve accurate transfer and avoid Forced deformation and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

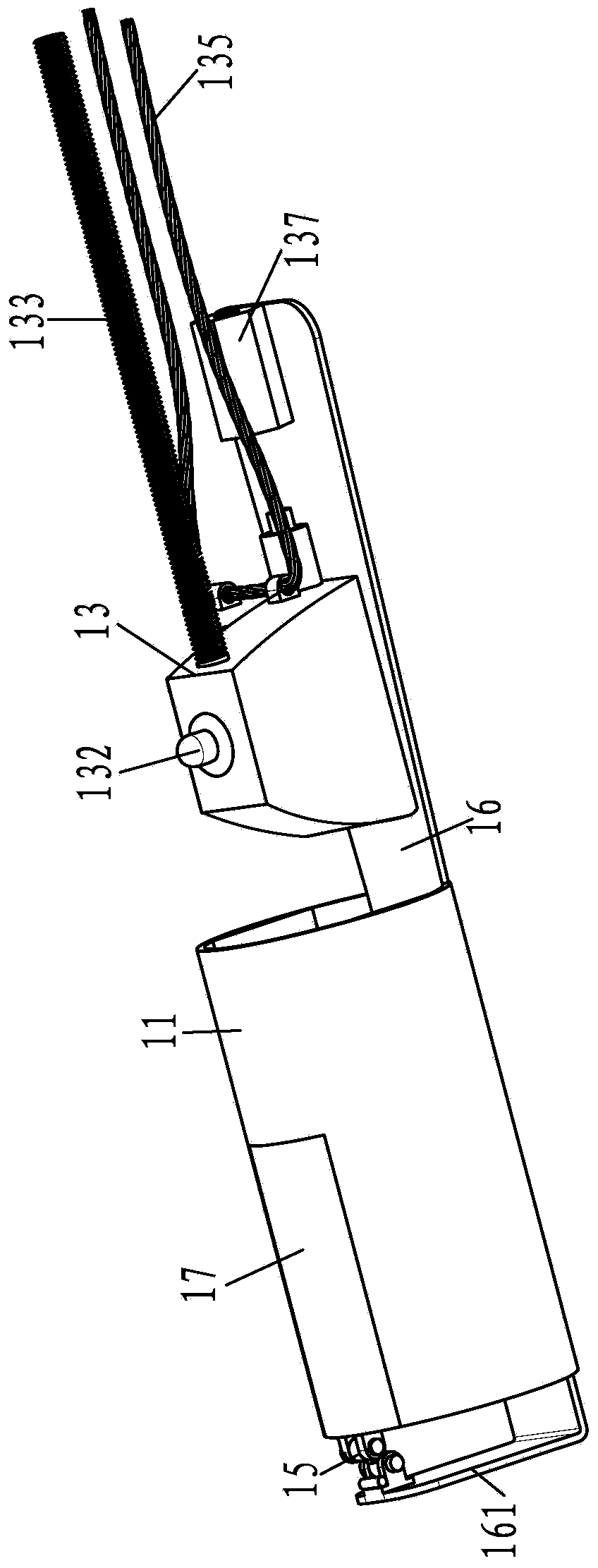

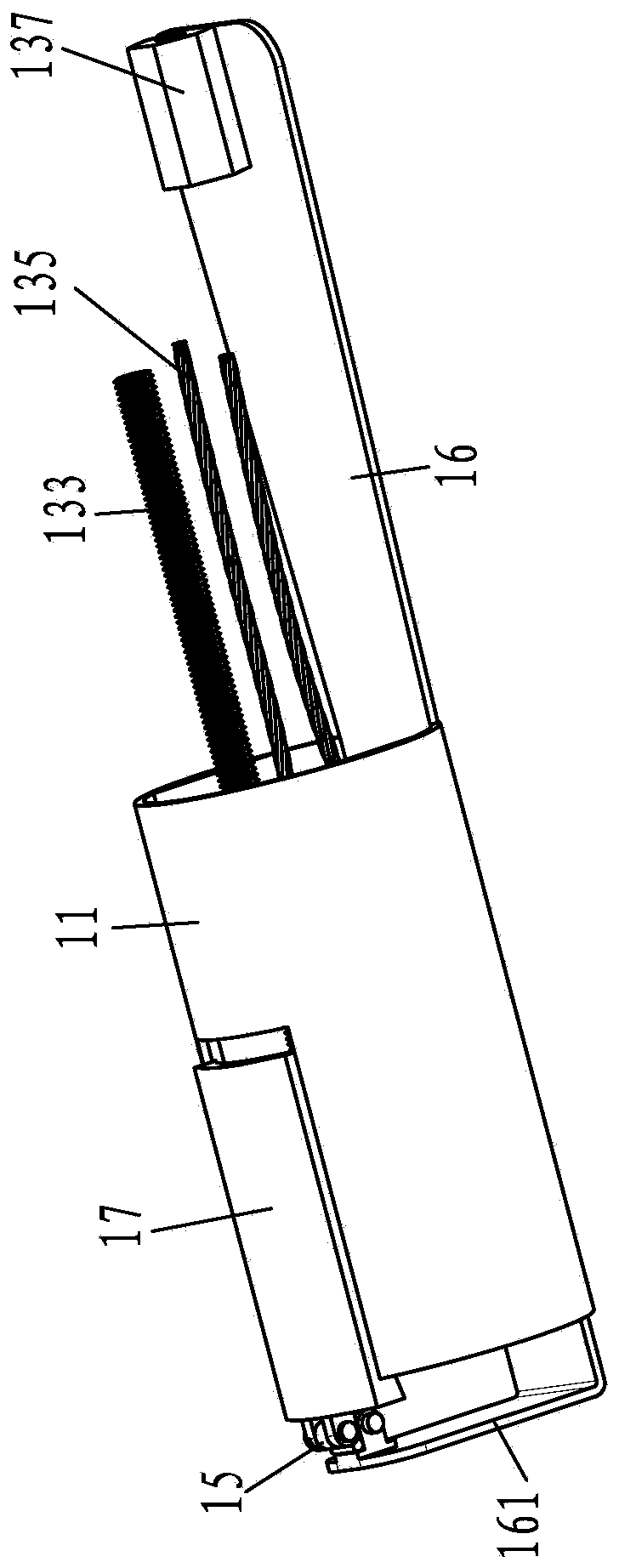

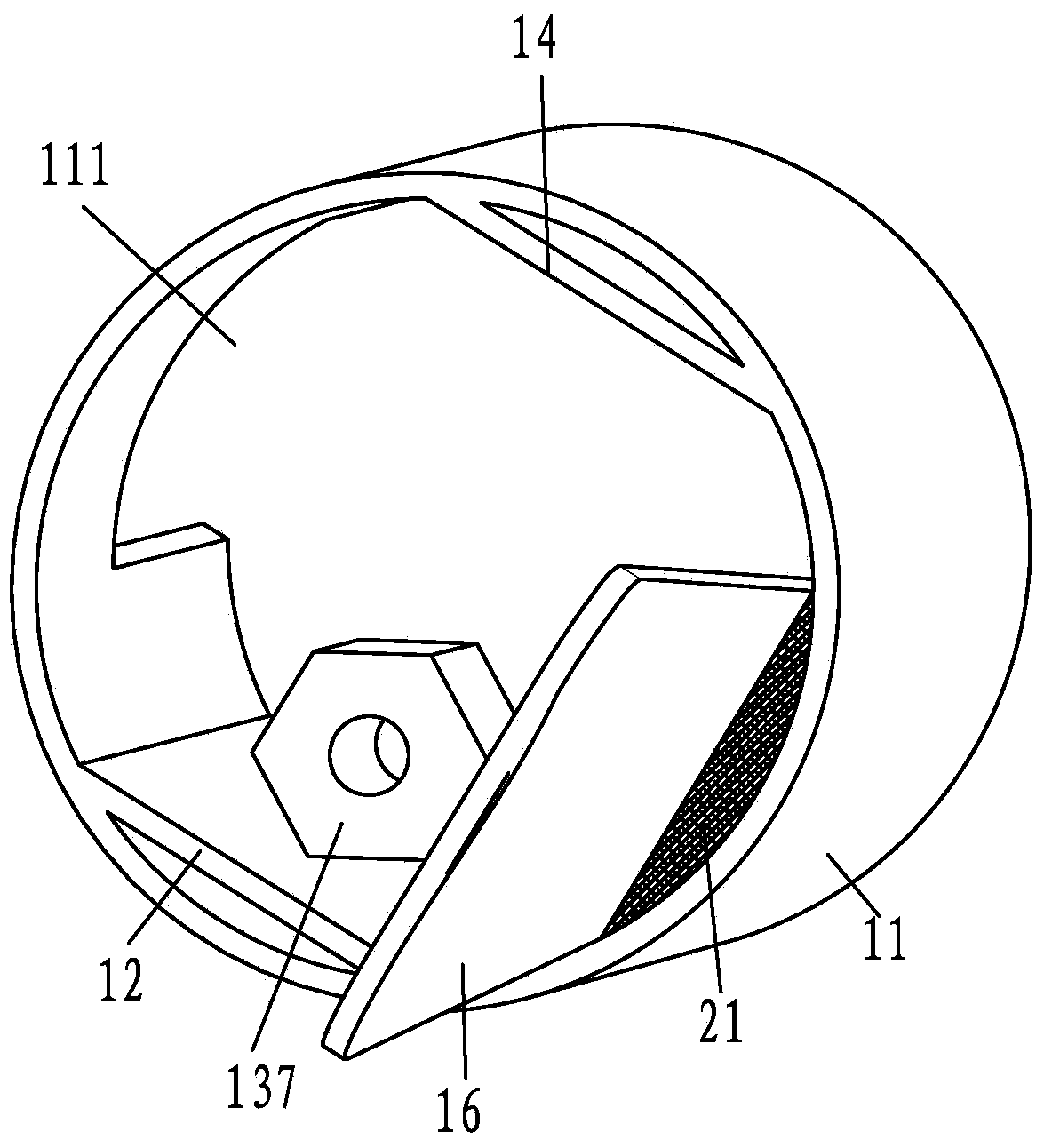

[0015] Such as figure 1 As shown, the recyclable ground stress testing device of the present invention includes a pipe body 11, a probe 13, and a movable plate 17, and the top of the left end of the pipe body 11 is provided with a gap 111, such as image 3 As shown, the inner bottom of the tube body 11 is welded with a first guide plate 16, and a filler 21 is arranged between the first guide plate 16 and the inner wall of the tube body 11, and the filler 21 is fully welded on the first guide plate 16 and the tube body 11. Between the steel, both ends of the first guide plate 16 are stretched out of the pipe body 11, the left end of the first guide plate 16 is welded with a limit plate 161, the limit plate 161 is perpendicular to the first guide plate 16, the limit plate 161 Connecting rod 15 is hinged on the top, and the other end of connecting rod 15 is hinged with movable plate 17, and the thickness of movable plate 17 gradually becomes thinner from hinged end to free end, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com