Small-fault detection method and device based on multiple moving average

A technology of fault detection and moving average, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of poor fault detection effect and poor sensitivity of small faults, etc., to improve the detection effect and increase the robustness Stickiness, the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

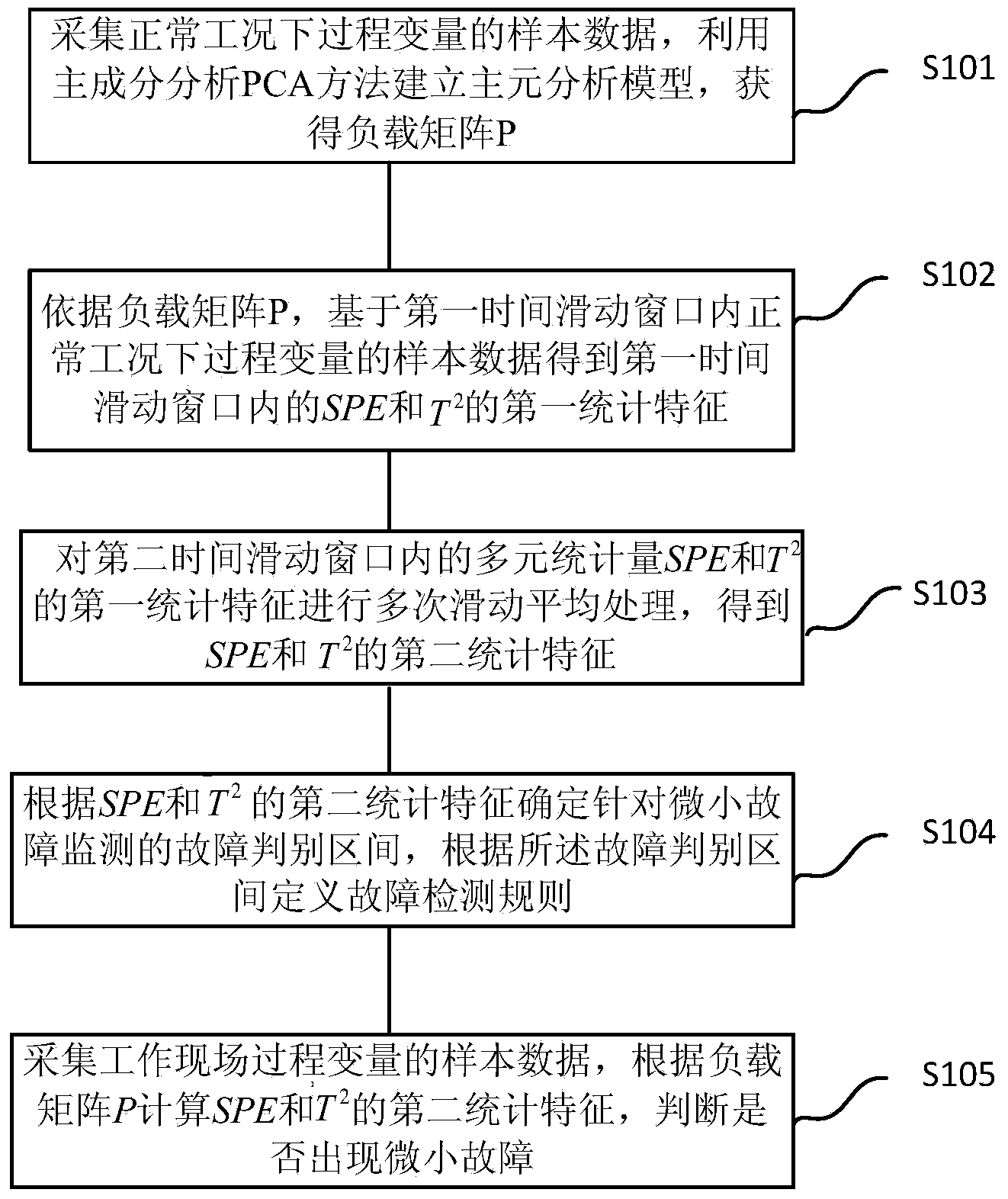

[0051] figure 1 Shown is a flow chart of the micro-fault detection method based on multiple moving averages according to Embodiment 1 of the present invention.

[0052] Step S101 , collect sample data of process variables under normal working conditions, use principal component analysis (PCA) method to establish a principal component analysis model, and obtain a load matrix P.

[0053] Specifically, collect normal working condition data, assuming that the detected object contains m sensors, then x∈R m ; Each sensor has n independent samples, where n is the total number of samples. Then the data under normal working conditions can be collected and the following normal working condition measurement matrix X can be constructed 0 =[x 1 ,x 2 ,...,x n ] Τ ∈R n×m ;

[0054] Preprocess the normal working condition measurement matrix, and convert the normal working condition measurement matrix X 0 Subtract the corresponding variable mean from each column and divide by the corr...

Embodiment 2

[0111] This embodiment is the application of the micro-fault detection method based on multiple moving averages in the simulation model of the present invention. The measured value of the sensor in the selected industrial process is:

[0112] x 1 (k)=0.3723s 1 +0.6815s 2 +e 1

[0113] x 2 (k)=0.4890s 1 +0.2954s 2 +e 2 (18)

[0114] x 3 (k)=0.9842s 1 +0.1793s 2 +e 3

[0115] where x 1 ,x 2 ,x 3 is the measured value of the sensor; s 1 ,s 2 as the real state, and set s 1 =10,s 2 =12;e 1 ,e 2 ,e 3 Gaussian white noise with a standard deviation of 0.1, representing the measurement noise of the sensor.

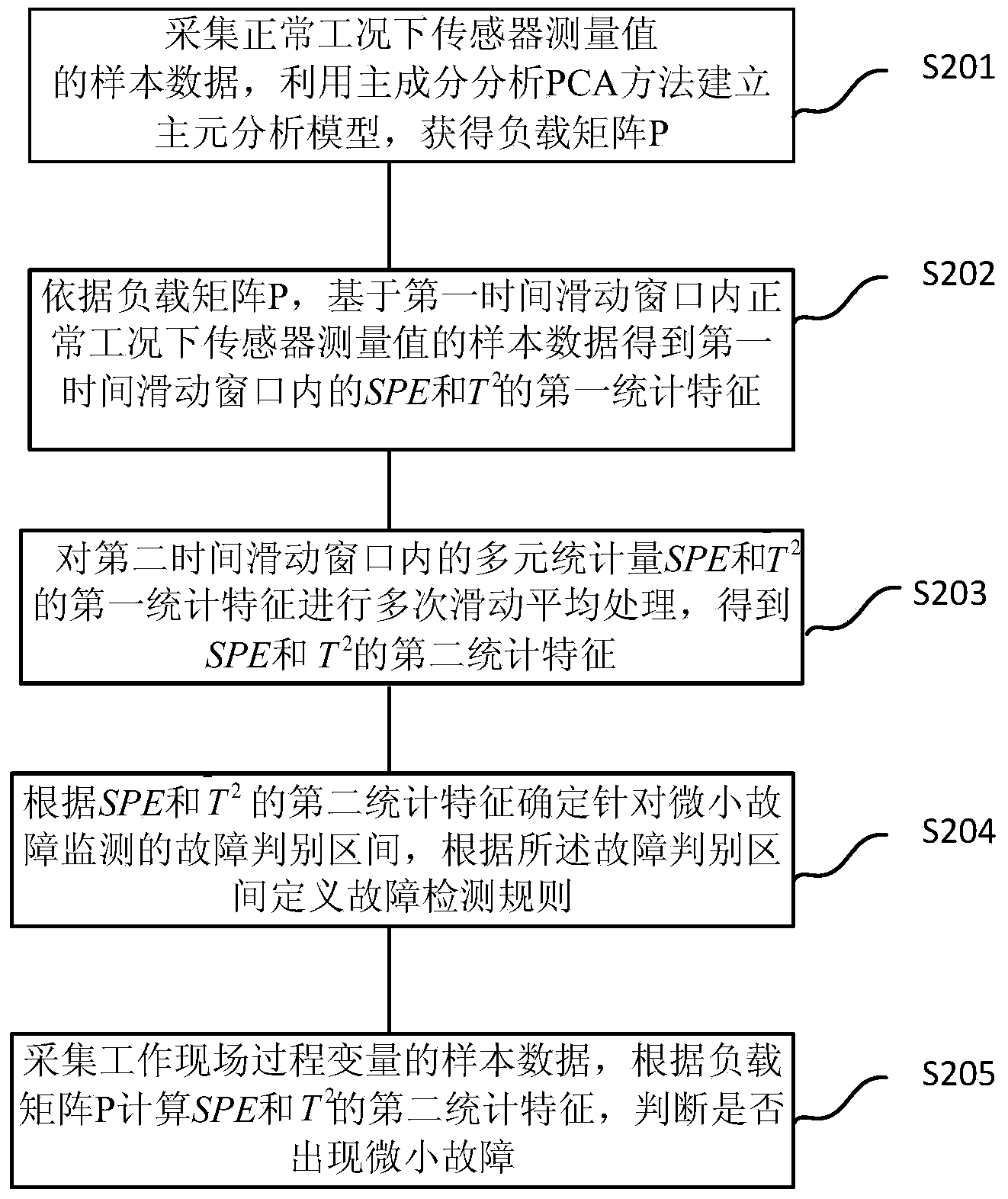

[0116] Step S201 , collecting sample data of sensor measurement values under normal working conditions, using the principal component analysis (PCA) method to establish a principal component analysis model, and obtaining a load matrix P.

[0117] Three sensors m=3, 5000 sets of normal measurement data are generated through this model, forming a matrix...

Embodiment 3

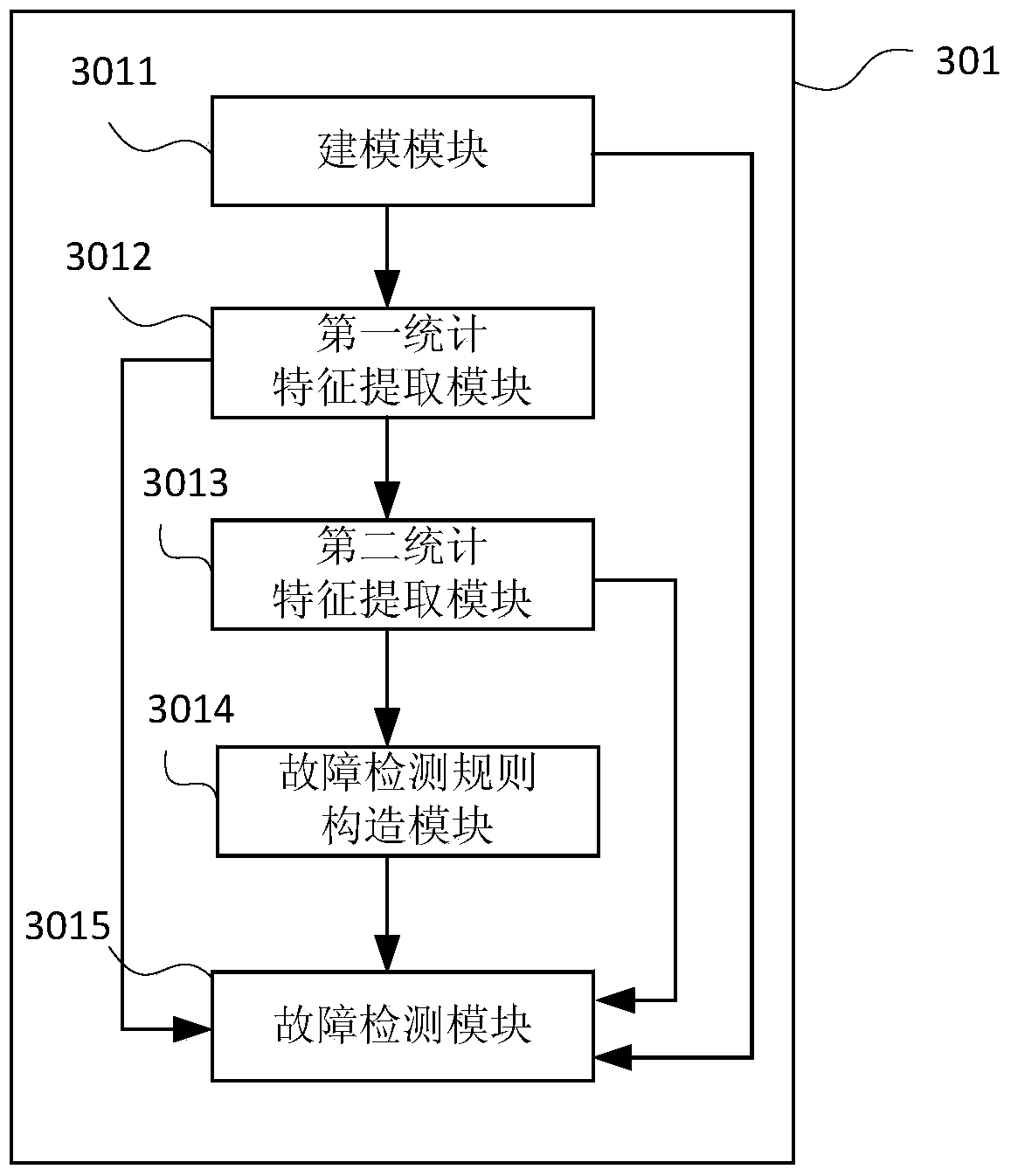

[0161] The present invention provides a small fault detection device based on multiple moving averages, such as image 3 A block diagram of the device is shown. Device 301 includes:

[0162] The modeling module 3011 is used to collect sample data of process variables under normal working conditions, establish a principal component analysis model by using the principal component analysis PCA method, and obtain the load matrix P;

[0163] Preferably, the modeling module 3011 can also include a preprocessing module, which is used to collect sample data of process variables under normal working conditions, and construct a normal working condition measurement matrix X 0 ; Perform standardized preprocessing on the normal working condition measurement matrix to obtain a normal measurement matrix X; based on the normal measurement matrix, use the principal component analysis PCA method to establish a principal component analysis model to obtain a load matrix P.

[0164] The first st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com