High-precision three-dimensional posture inertia measurement system and method based on MEMS (Micro Electro Mechanical Systems)

A three-dimensional attitude and inertial measurement technology, applied in directions such as navigation through velocity/acceleration measurement, which can solve the problems of low accuracy and high sensor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

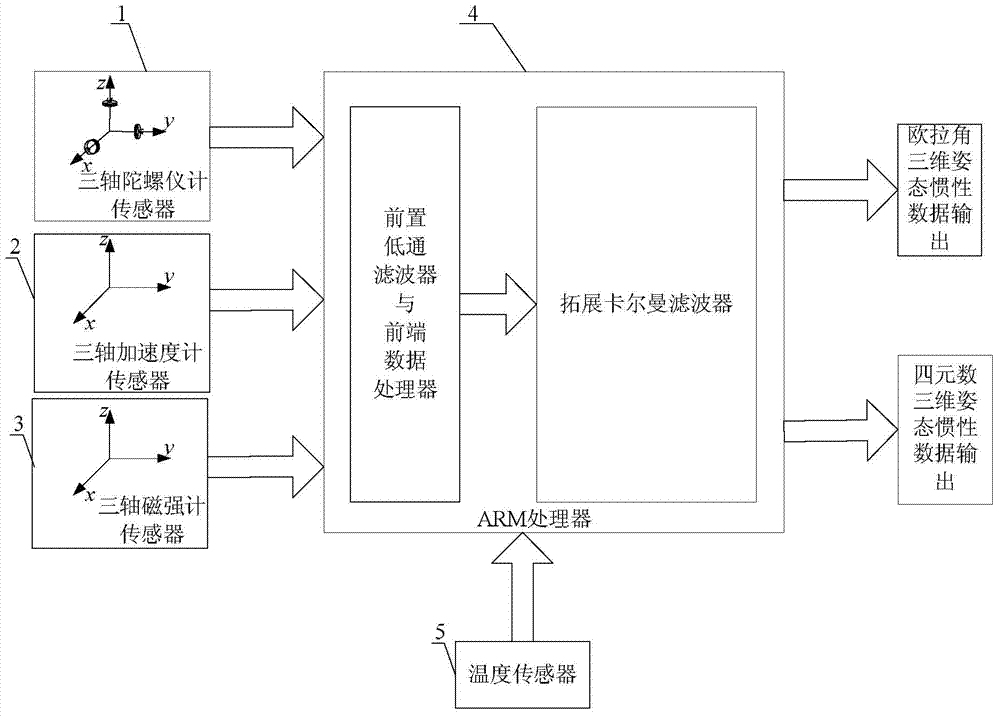

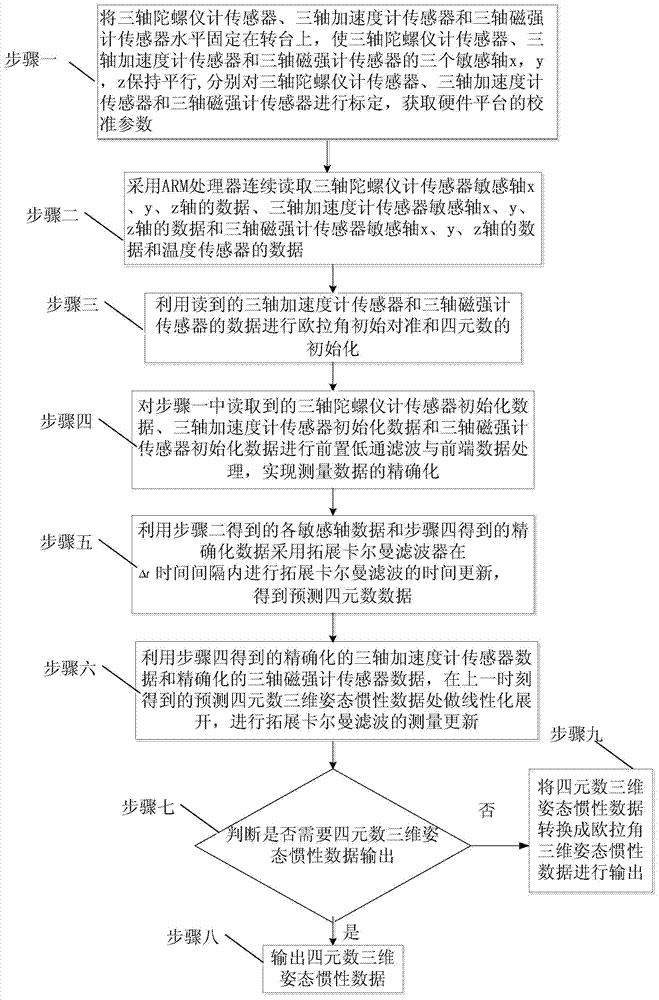

[0014] Specific implementation mode one: refer to figure 1 Specifically illustrate the present embodiment, a kind of MEMS-based high-precision three-dimensional attitude inertial measurement system described in the present embodiment, it comprises microelectromechanical type inertial measurement device, it also comprises ARM processor 4 and temperature sensor 5,

[0015] The MEMS inertial measurement device includes a three-axis gyroscope sensor 1, a three-axis accelerometer sensor 2 and a three-axis magnetometer sensor 3,

[0016] The three-axis gyroscope sensor 1 is used to measure and obtain the angular velocity, and send the angular velocity data obtained by the measurement to the ARM processor 4,

[0017] The three-axis accelerometer sensor 2 is used to measure and obtain the acceleration, and the acceleration data obtained by the measurement is sent to the ARM processor 4,

[0018] The three-axis magnetometer sensor 3 is used to measure and obtain the magnetic intensity...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and the MEMS-based high-precision three-dimensional attitude inertial measurement system described in Embodiment 1 is that the ARM processor 4 is realized by the model STM32F405.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and the MEMS-based high-precision three-dimensional attitude inertial measurement system described in Embodiment 1 is that the three-axis gyroscope sensor 1 is implemented with a model of MPU6050.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com