A wind power generation system that relies on steel structure composite towers to provide stable power

A technology for wind power generation system and stable power supply, which is applied in the direction of wind power generators storing gravitational potential energy, wind power generation, installation/supporting wind power motor configuration, etc. Problems such as battery and lithium battery pollution, difficult air tightness testing, etc., to solve the problem of unstable power supply, facilitate maintenance and debugging, and improve load-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

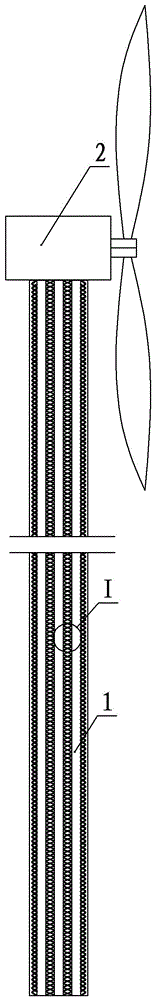

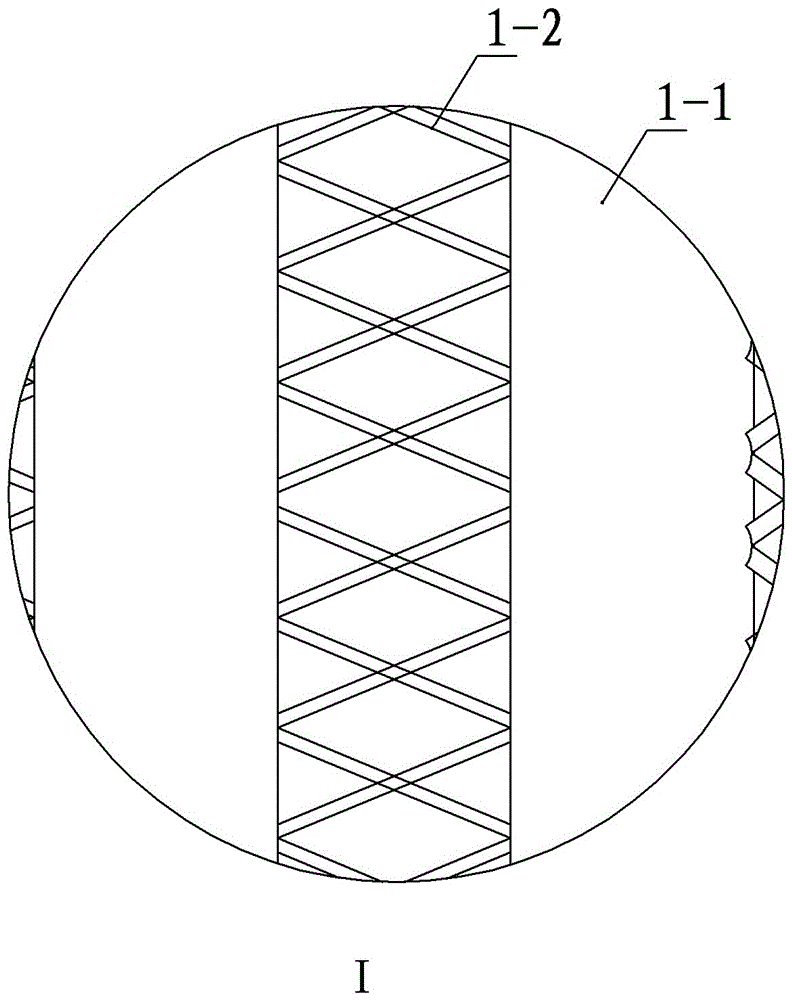

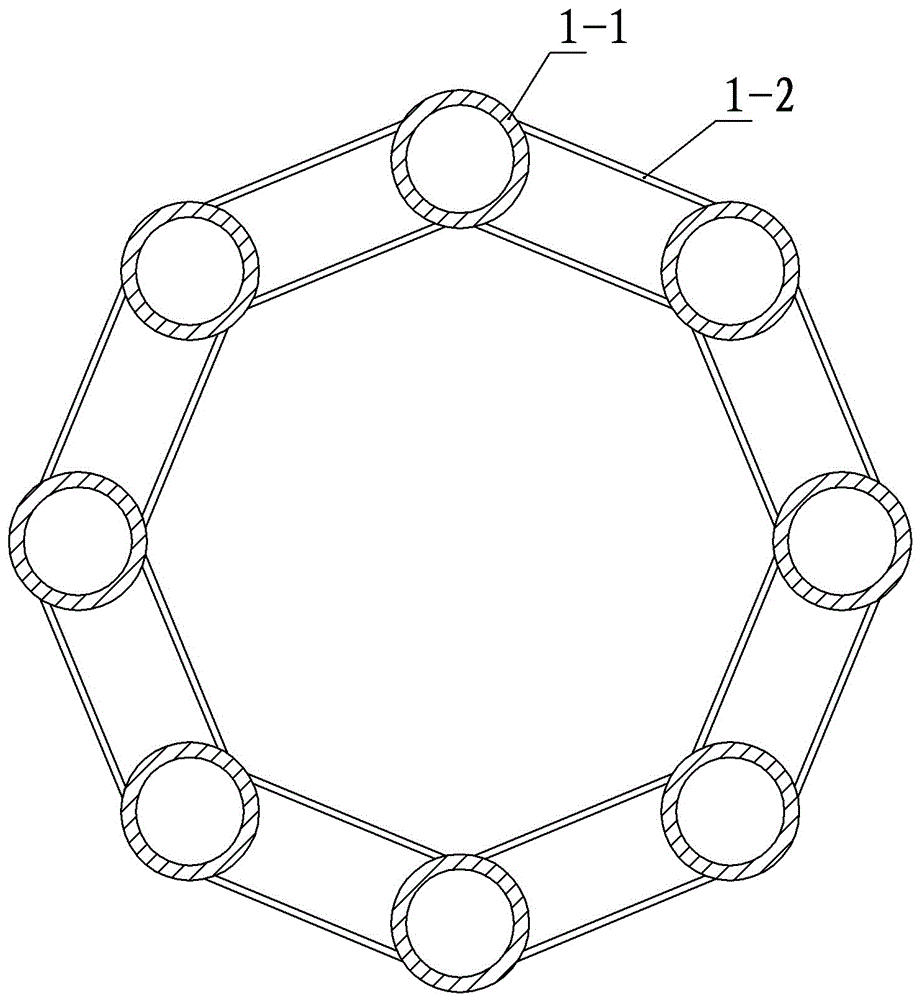

[0037] Embodiment one: see Figure 1-3 , Figure 14 , Figure 16 In the figure, a wind power generation system that relies on a steel structure composite tower to provide a stable power supply includes a fan, a tower, and a control module. The tower includes at least several elongated cylindrical pressure tanks, and the several pressure tanks Arranged around a central axis, adjacent pressure tanks are fixedly connected by steel structure trusses; the lower end of the tower body is fixed on the ground, and a fan is installed at the upper end of the tower body; several pressure tanks form a group of two Energy storage and energy release unit, liquid medium and compressed air are provided in the pressure tank of each energy storage and energy release unit, and the reversible compression device is connected between the two pressure tanks through pipelines, and each reversible compression device They are all connected to the control module, the output cables of the fan are connec...

Embodiment 2

[0044] Embodiment two: see Figure 1-2 , Figure 4 , Figure 14 , Figure 16 , Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the cross section of the pressure tank described in Embodiment 2 is trapezoidal.

[0045] The outer surface of the tower body in Embodiment 2 may also be provided with a sun-proof and heat-insulating layer; the sun-proof and heat-insulating layer is a photovoltaic panel. It can supplement wind power generation while solving the problem that the pressure tank is afraid of high temperature exposure, such as Figure 9 As shown, this structure is also a measure that kills two birds with one stone.

Embodiment 3

[0046] Embodiment three: see Figure 1-2 , Figure 5 , Figure 14 , Figure 16 , Embodiment 3 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the cross-section of the pressure tank described in Embodiment 3 is square.

[0047] The outer surface of the tower body in Embodiment 3 may also be provided with a sun-proof and heat-insulating layer; the sun-proof and heat-insulating layer is a photovoltaic panel. It can supplement wind power generation while solving the problem that the pressure tank is afraid of high temperature exposure, such as Figure 10 As shown, this structure is also a measure that kills two birds with one stone.

[0048] The specific examples of the reversible fluid pump-motor and reversible motor-generator in the reversible compression device mentioned in the above three embodiments can refer to the description of the Chinese invention patent with the patent number: 201110137038.X, in which there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com