Starter

一种起动器、动铁心的技术,应用在发动机的起动、继电器、发动机用电动机起动等方向,能够解决高加工精度、成本上升、空间部负压易产生偏差等问题,达到抑制驱动弹簧挠曲、啮合性提高、防止啮合不良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

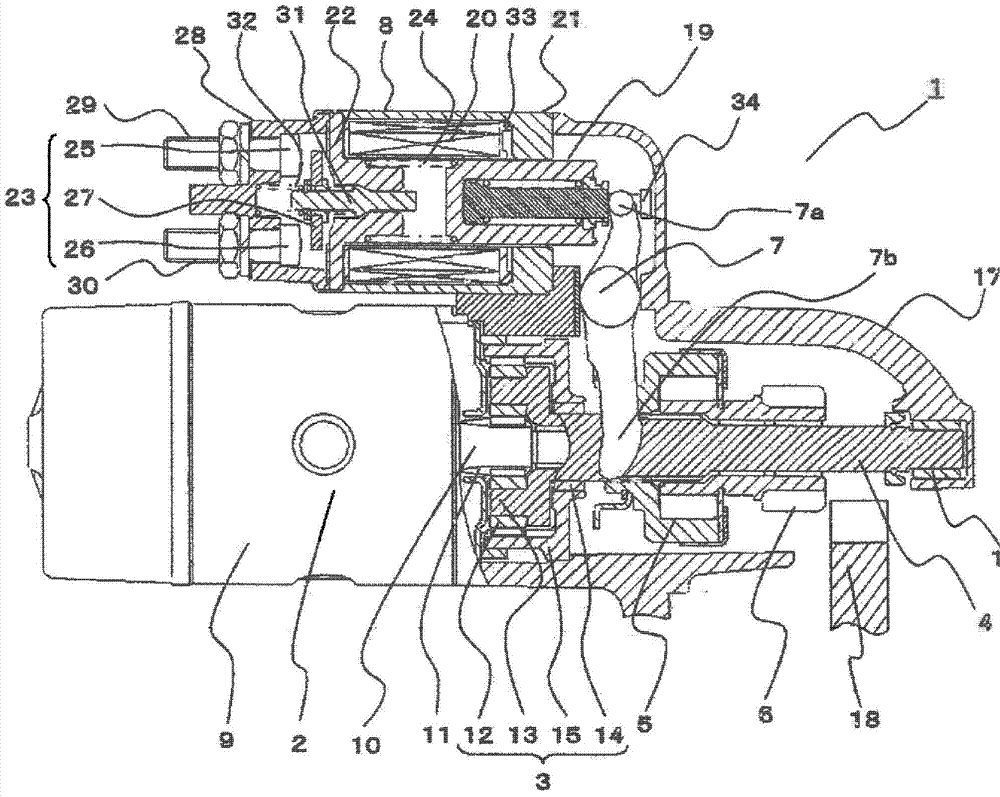

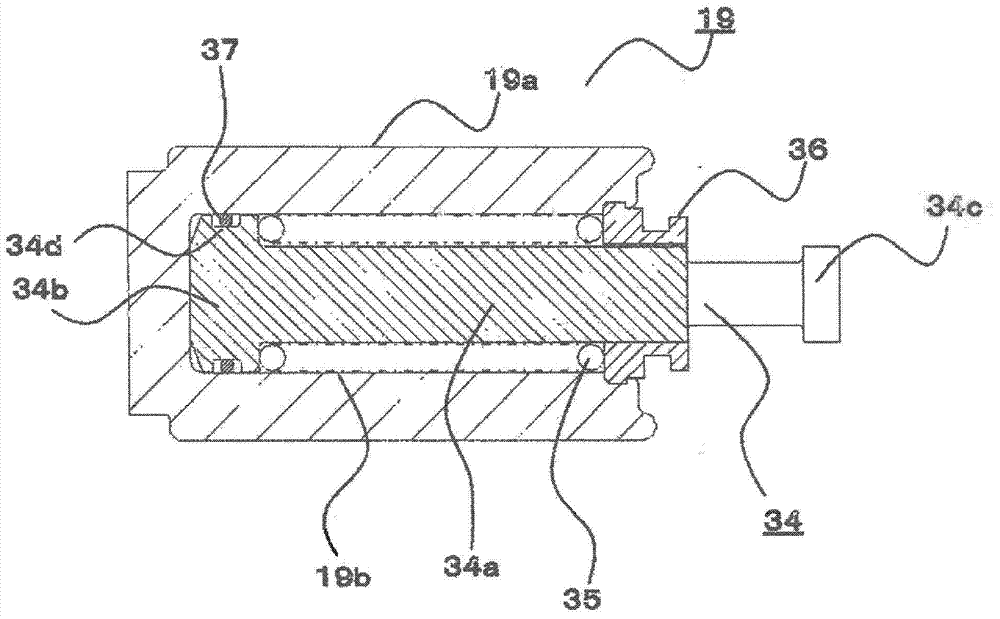

[0056] figure 1 is a partial sectional view showing the basic structure of the starter according to Embodiment 1 of the present invention, figure 2 yes figure 1 A cross-sectional view of the main part of the plunger in .

[0057] Such as figure 1 As shown, the starter 1 is composed of a motor 2, a reduction gear 3, an output shaft 4, a pinion 6, an electromagnetic switch 8, etc., wherein the motor 2 generates a rotational force, and the reduction gear 3 decelerates the rotational speed of the motor 2, The output shaft 4 is driven by the motor 2 through the reduction gear 3 , the pinion 6 and the clutch 5 are integrally arranged on the output shaft 4 , and the electromagnetic switch 8 directs the clutch 5 and the pinion 6 to the motor through the shift lever 7 . in the opposite direction ( figure 1 on the right side) and turn on and off the energizing circuit of motor 2.

[0058] The motor 2 is a well-known DC motor, which has an excitation system (not shown) formed by ar...

Embodiment approach 2

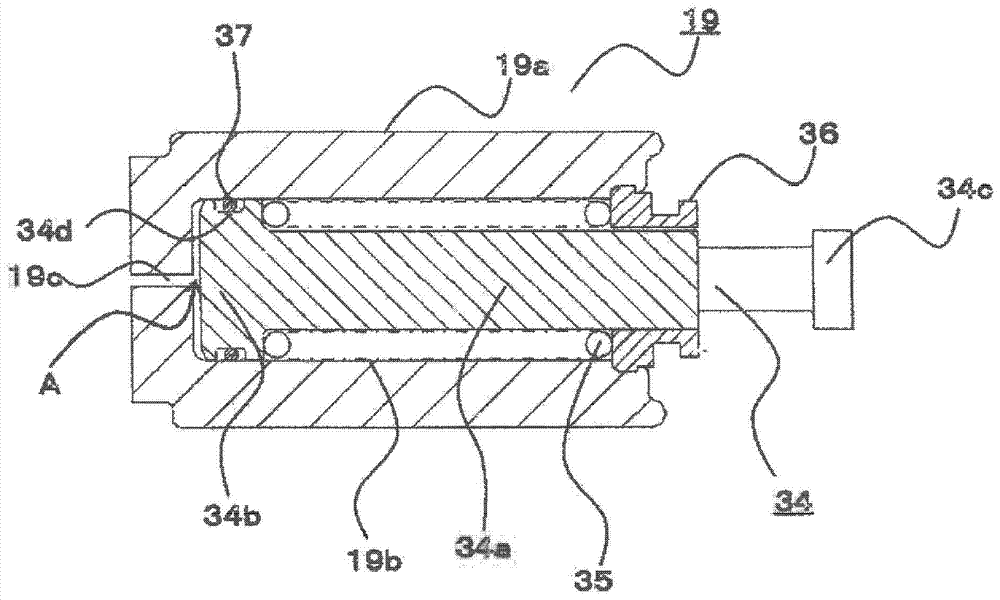

[0105] Figure 5 It is a perspective view of main parts showing the flange portion of the hook portion 34 according to Embodiment 2 of the present invention.

[0106] Figure 6A and Figure 6B is a sectional view of main parts of the plunger according to Embodiment 2 of the present invention, wherein Figure 6A It is a cross-sectional view showing a state in which the movable iron core moves while flexing the drive spring, Figure 6B It is a cross-sectional view showing a state in which the hook moves while releasing the drive spring.

[0107] In Embodiment 2, the elastic body 37 is annularly provided on the entire circumference of the first annular groove 34d provided in the hook portion 34. Figure 5 As shown, a second flow path groove portion 34g is formed in the first annular groove portion 34d. The second flow path groove portion 34g extends in the axial direction and has a depth greater than that of the first annular groove portion 34d. A second flow path area enlar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com