Novel fabricated light framework plate

A skeleton plate and assembly technology, applied in building materials, building components, buildings, etc., can solve the problems of difficult rapid large-scale industrial production, consumption of cement and perlite resources, complicated manufacturing processes, etc., and achieve easy large-scale industrial production , material saving, simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

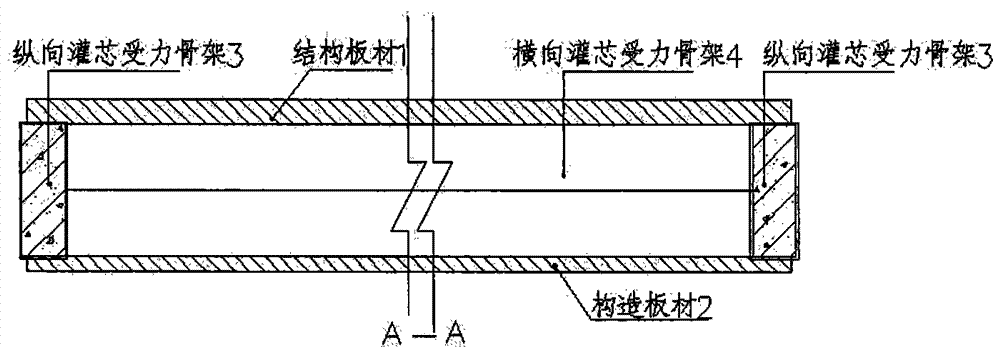

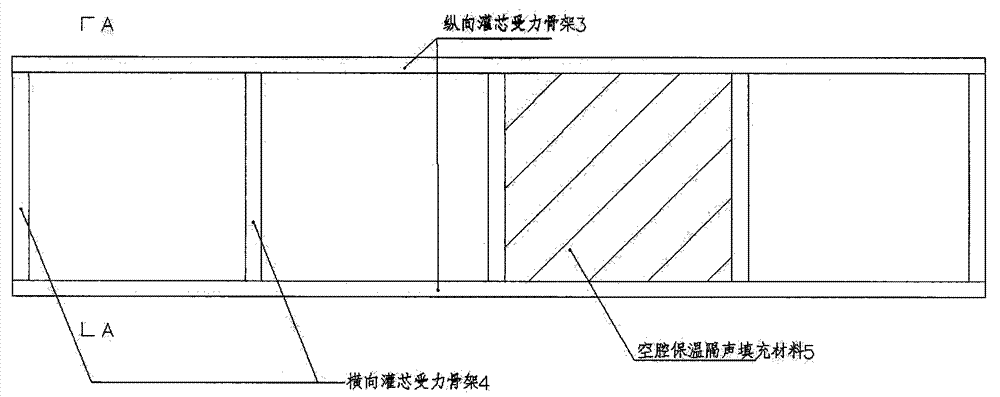

[0017] See attached figure in the manual Figure 1 ~ Figure 3 , the new assembled skeleton plate provided by the present invention includes a force-bearing structural plate 1, a non-structural force-bearing structural plate 2, a longitudinal core-filling force framework 3 and a transverse core-filling force framework 4, and the longitudinal core-filling The lattice space between the force frame 3 and the transverse core-filled force frame 4 can be filled with thermal insulation, sound insulation and heat insulation materials 5 according to functional requirements.

[0018] The longitudinal core-filling frame 3 and the transverse core-filling frame 4 can be connected together by welding or spot welding with high-strength structural adhesive. The glue can be integrally bonded and cured with the longitudinal core-filling force frame 3 and the transverse core-filling force frame 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com