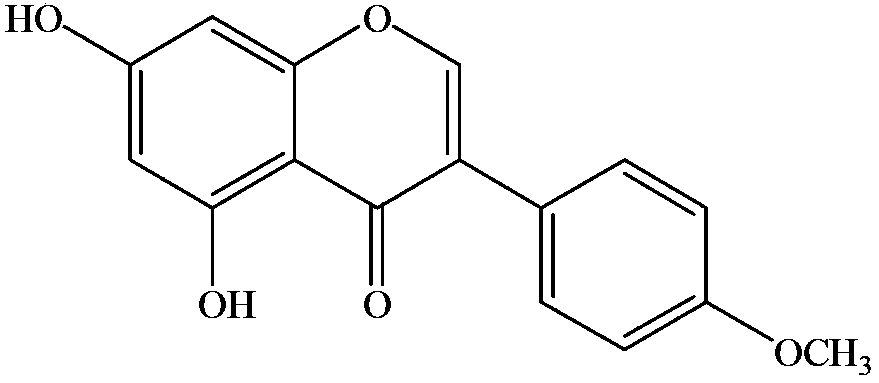

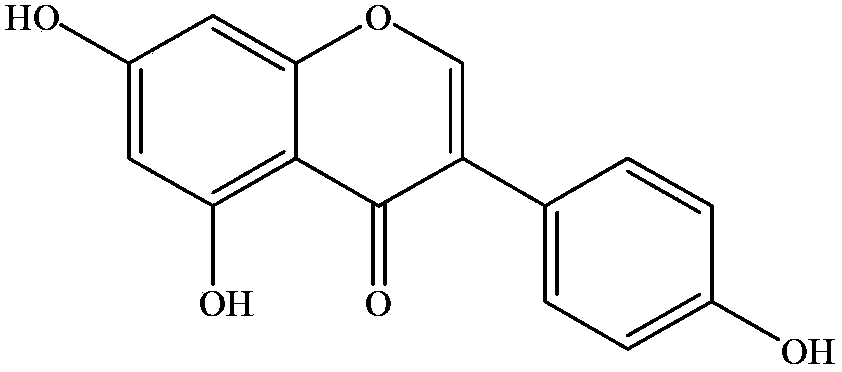

Method for extracting, separating and purifying isoflavone active components biochanin A and genistein from dalbergia odorifera T.Chen leaves

A technology for chickpea sprouts and genistein, which is applied in the directions of organic chemistry, fermentation, etc., can solve the problems of high separation cost and difficulty in separating chickpea sprouts A, and achieves low dosage, low separation cost, high efficiency and reasonableness. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

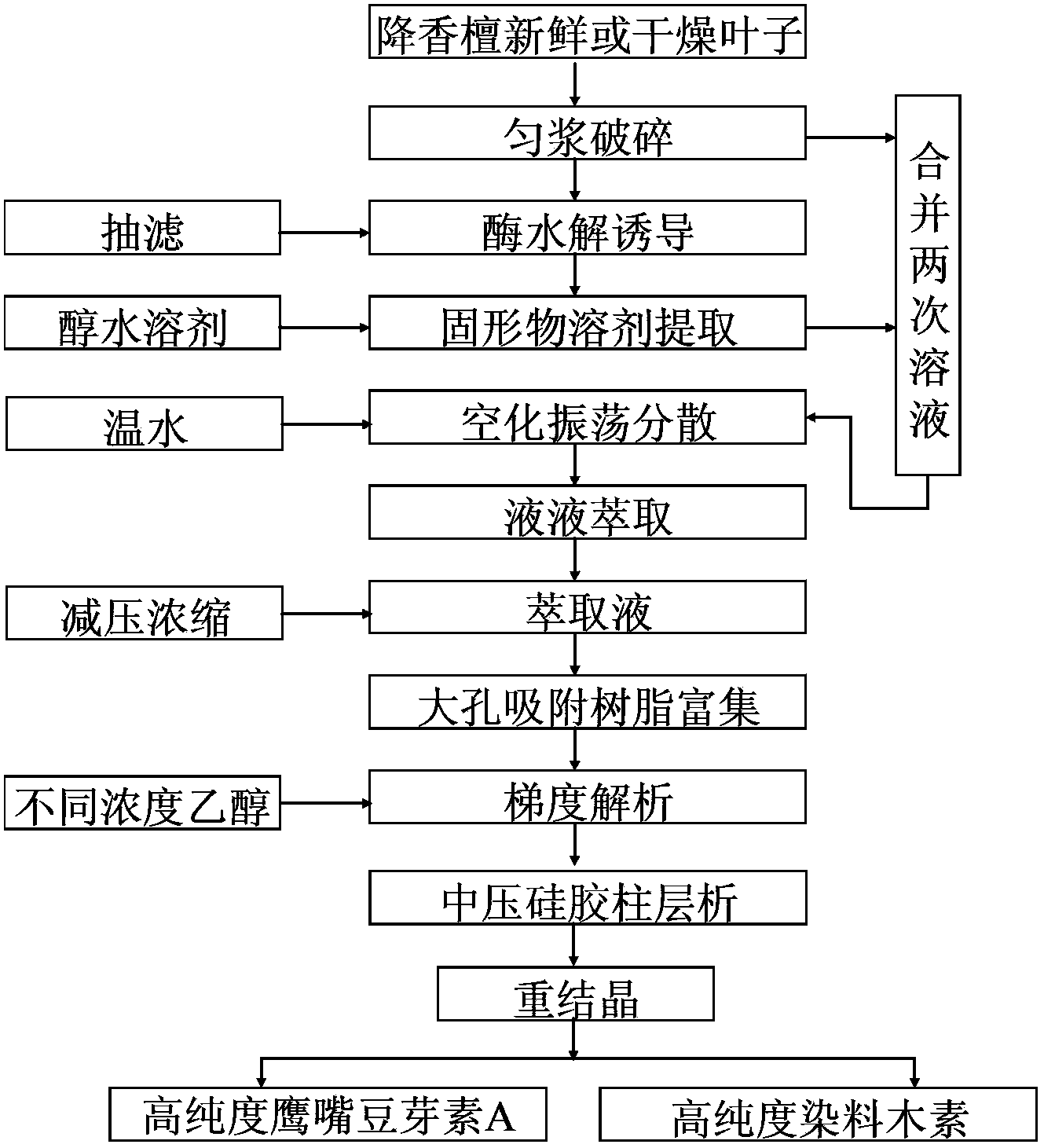

[0021] Example 1 Extraction, Separation and Purification of Biochanin A and Genistein in Sandalwood Leaf

[0022] Take 1000g of dry Dalbergia leaves, add water, take 0.2% solid weight compound enzyme (cellulase, pectinase, glucosidase) activated compound enzyme solution, add it to the homogenate induction slurry, and continuously homogenize and break Enzyme induction 8min. After induction of homogenate crushing and enzymatic hydrolysis, the obtained solids were extracted with 70% ethanol ultrasonically for 5 times, each time for 60 minutes. Cavitation vibration dispersion for 40 minutes, static for 20 minutes, the obtained dispersion was extracted 3 times with 6.5L ethyl acetate, the extract was concentrated under reduced pressure and evaporated to dryness, the obtained solid was suspended in water, and the concentration of the liquid was configured to be 15 mg / mL of suspension drug solution, at the same time, ADS-5 macroporous adsorption resin was packed into a column by we...

example 2

[0023] Example 2 Extraction, Separation and Purification of Biochanin A and Genistein in Sandalwood Leaf

[0024]Take 3.56kg of fresh Dalbergia leaves (dry weight is 1kg), take 1.5% solid weight compound enzyme (cellulase, pectinase, glucosidase) activated compound enzyme solution and add it to the homogenate induction slurry , continuous homogenization and crushing enzyme induction for 10 min. After induction of homogenate crushing and enzymatic hydrolysis, suction filtration, the obtained solids were extracted 5 times with 95% ethanol ultrasonic assistance, each time for 60 minutes, and then the enzymatic hydrolysis liquid and ethanol extract were combined and concentrated under reduced pressure, then added 40°C water for emptying Shake and disperse for 30 minutes, stand still for 15 minutes, extract the obtained dispersion three times with ethyl acetate, concentrate the extract under reduced pressure and evaporate to dryness, suspend the obtained solid in water, and prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com