Latex and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

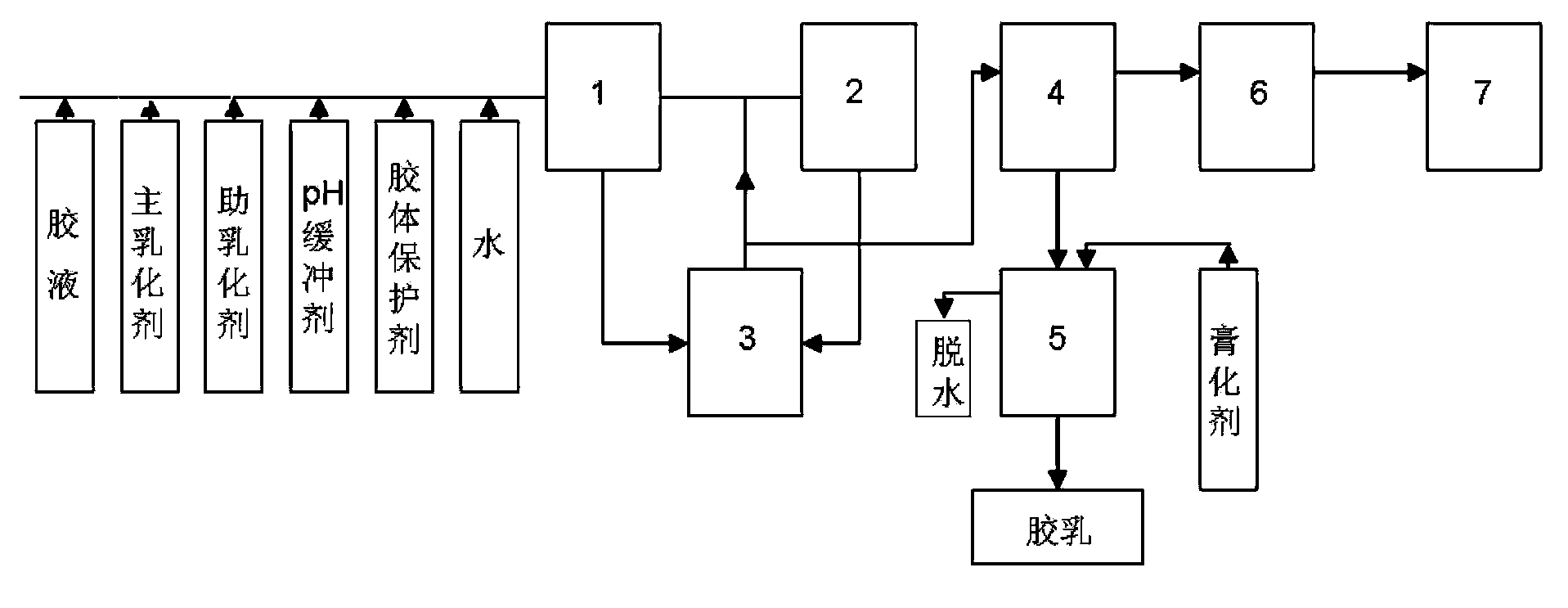

[0018] The preparation method of the latex provided by the present invention includes mixing and emulsifying the glue, the main emulsifier, the co-emulsifier, the pH regulator and water and removing the organic solvent, and then mixing the product after removing the organic solvent with the creaming agent contact and remove part of the water; the glue is an organic solution containing a polymer, the main emulsifier is fatty acid, and the co-emulsifier is fatty acid salt.

[0019] According to the present invention, although the latex with higher solid content can be obtained as long as the above method is followed, in order to avoid significant changes in the pH value in the system and to make the obtained latex more stable, preferably, the preparation method of the latex It also includes mixing and emulsifying the pH buffer and the colloidal protective agent together with the glue, the main emulsifier, the auxiliary emulsifier, the pH regulator and water.

[0020] According t...

Embodiment 1

[0034] This embodiment is used for illustrating latex provided by the invention and preparation method thereof.

[0035] according to figure 1 Shown process carries out the preparation of latex, concrete steps are as follows:

[0036] Add 1000 parts by weight of polyisoprene with a concentration of 10% by weight (Beijing Linshi Refined Chemical New Material Co., Ltd., with a weight average molecular weight of 400,000) in cyclohexane glue into crude latex preparation tank 1, and at 20°C, At a stirring rate of 60r / min, 4 parts by weight of oleic acid were added and mixed uniformly to obtain a mixed product; , 1.2 parts by weight concentration of potassium dihydrogen phosphate aqueous solution of 5% by weight, 3 parts by weight of polyvinyl alcohol aqueous solution with a concentration of 2% by weight (wherein, polyvinyl alcohol was purchased from Guangzhou Qisheng Chemical Co., Ltd., the brand is BP-24 , the same below) and 600 parts by weight of water were added to the above ...

Embodiment 2

[0038] This embodiment is used for illustrating latex provided by the invention and preparation method thereof.

[0039] according to figure 1 Shown process carries out the preparation of latex, concrete steps are as follows:

[0040] Add 1,000 parts by weight of butadiene rubber (purchased from Shanghai Duokang Industrial Development Co., Ltd., brand BR9000) cyclohexane glue solution with a concentration of 10% by weight into the crude latex preparation tank 1, at 40°C, at 100r / min Add 2 parts by weight of oleic acid and mix evenly at a stirring rate of 200 r / min to obtain a mixed product; then, at 40 ° C and a stirring rate of 200 r / min, 10 parts by weight of a sodium oleate aqueous solution with a concentration of 5 wt %, 3 parts by weight A concentration of 5% by weight potassium dihydrogen phosphate aqueous solution, 10 parts by weight of a 20% by weight polyvinyl alcohol aqueous solution and 600 parts by weight of water are added to the above-mentioned mixed product, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com