Laser cutting method and laser cutting system

A laser cutting and laser beam technology, applied in laser welding equipment, glass cutting equipment, glass manufacturing equipment, etc., can solve the problems of substrate separation, poor control of process parameters, and difficulty in obtaining high-quality surface cutting effects, etc., to achieve Guaranteed effect of successful separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

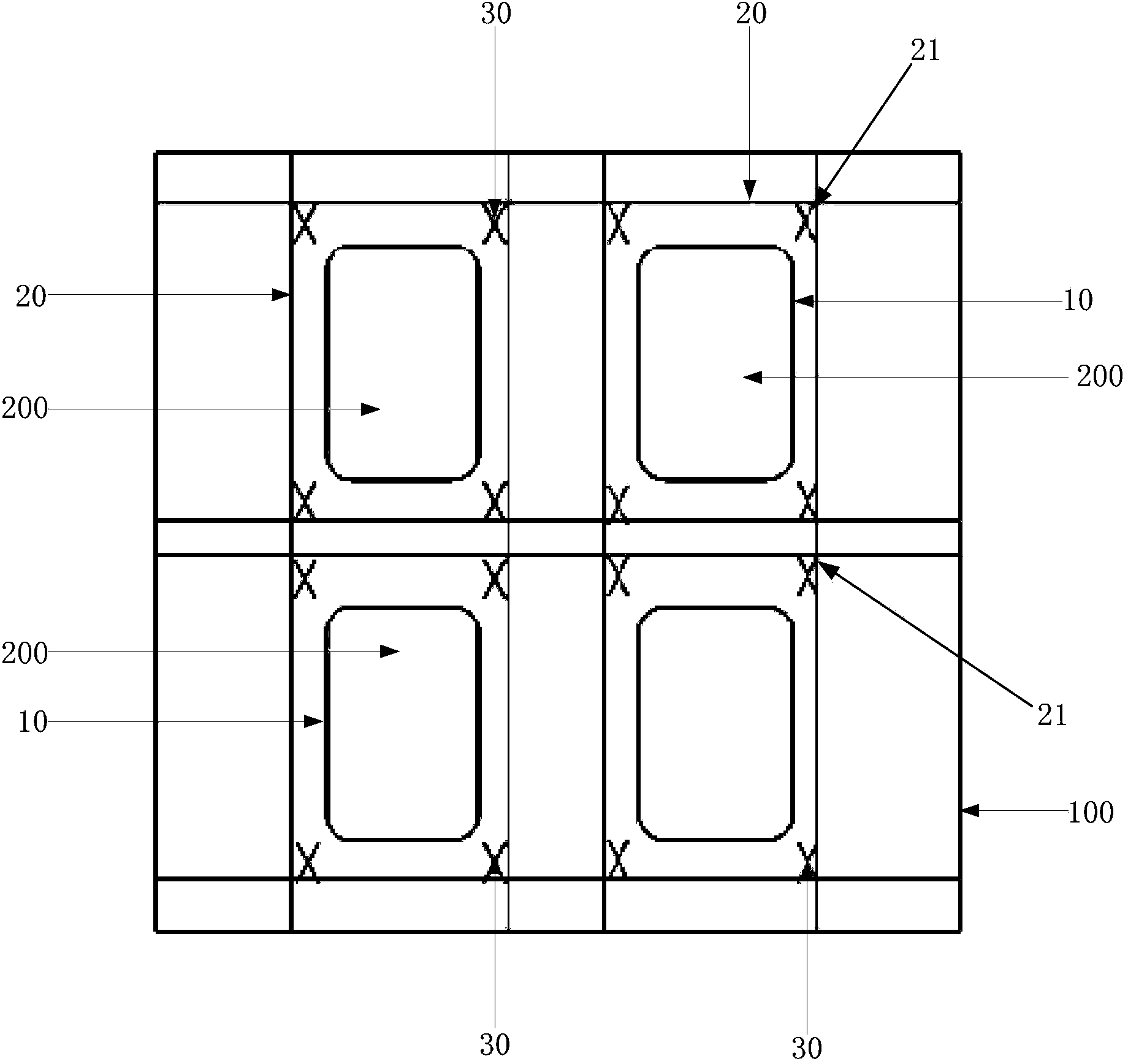

[0050] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to specific embodiments and accompanying drawings.

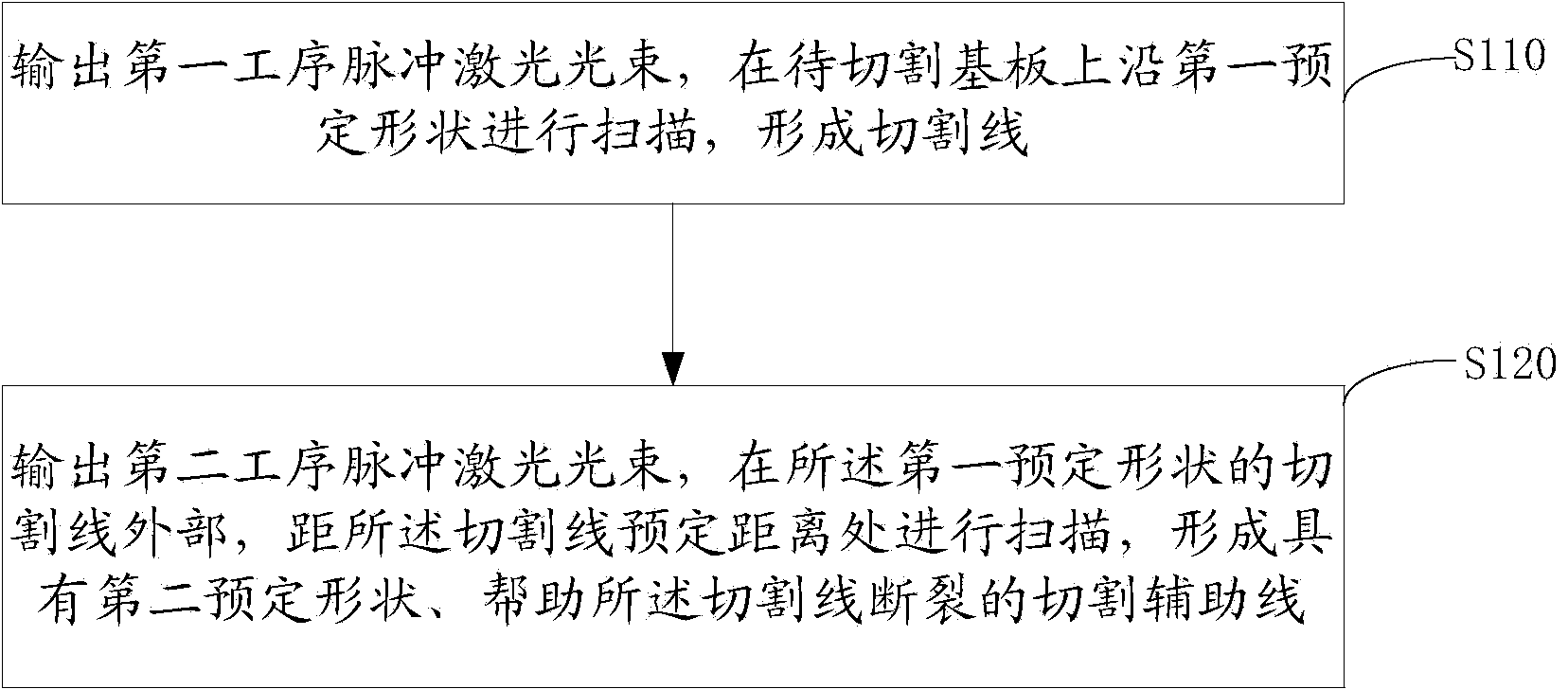

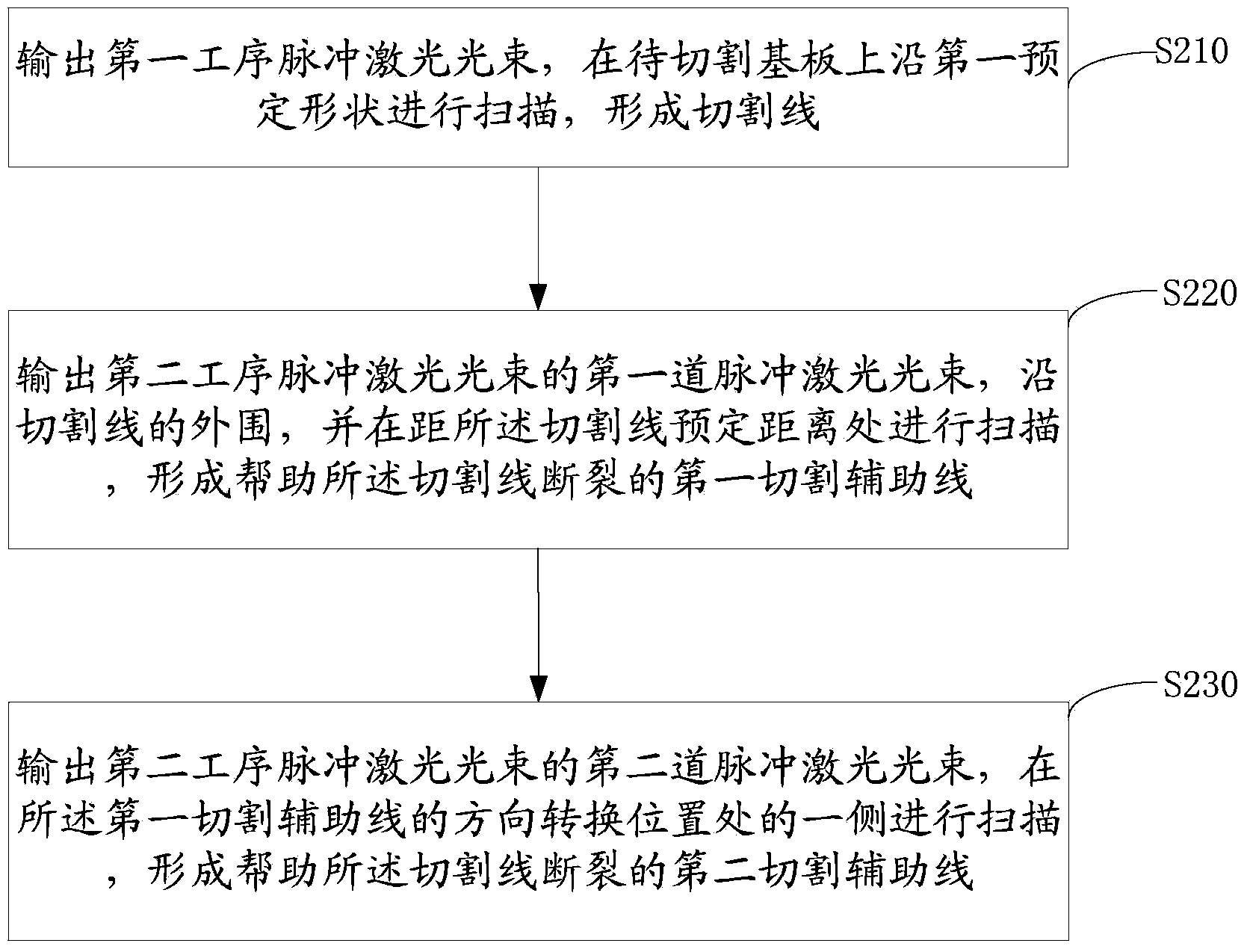

[0051] The laser cutting method of the present invention includes:

[0052] Forming a cutting line with a first predetermined shape on the substrate to be cut; wherein the first predetermined shape is the shape to be cut;

[0053] A cutting auxiliary line having a second predetermined shape for helping the cutting line break is formed on the substrate to be cut, wherein the cutting auxiliary line is located outside the cutting line of the first predetermined shape.

[0054]Adopting the laser cutting method of the present invention, by forming the cutting auxiliary line outside the cutting line, the stress damage point on the substrate is increased when the laser cutting forms the cutting line, which is convenient for the division and separation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com