Recovery device for oil gas discharged when light oil products are loaded into trucks or ships

A light oil product and recovery device technology, which is applied in distribution devices, special distribution devices, liquid distribution, transportation or transfer devices, etc., can solve the problems of difficult sealing loading, oil and gas leakage, and complicated sealing loading, etc., to achieve Elimination of forced volatilization, increased processing load, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

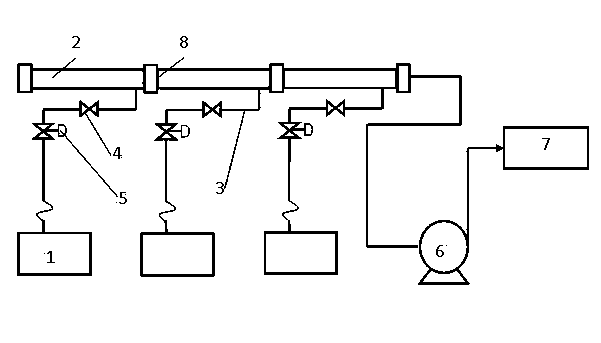

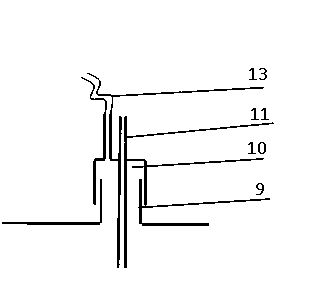

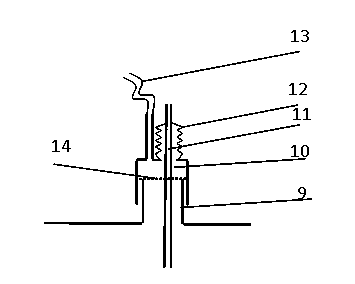

[0025] The composition and operation mode of the device of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] Such as figure 1 As shown, the device of the present invention includes an oil and gas recovery part and an oil and gas collection part, wherein the oil and gas collection part includes an oil and gas delivery pipeline 2, an oil and gas collection pipeline 3 and a liquid ring compressor 6, wherein the oil and gas delivery pipeline 2 can be composed of several sections of standard pipe fittings, the standard The pipe fittings are connected by flanges 8 . The oil and gas collection pipeline 3 is arranged horizontally or vertically, and the middle position of the oil and gas collection pipeline 3 is provided with a vortex flowmeter 4. A regulating valve 5 is provided, and the regulating valve 5 can be arranged before or after the vortex flowmeter 4 . One end of the oil and gas collection pipeline 3 communicates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com