Method for binding blank of double-edged fine-toothed comb

A grate and mold technology, which is applied in the field of grate for daily necessities, can solve the problems of fine and complex craftsmanship, numerous processes, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

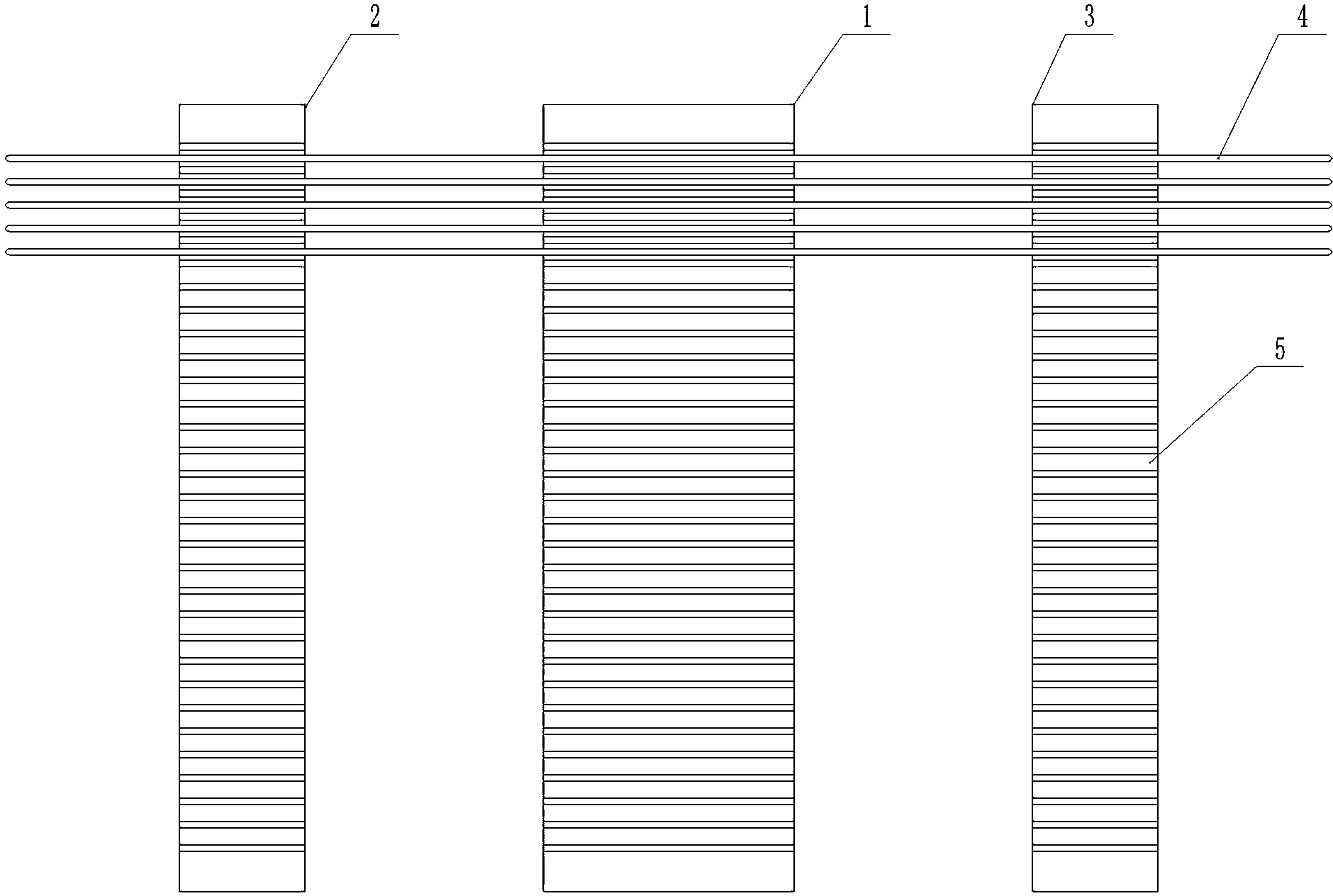

[0021] refer to figure 1 , figure 2 , a kind of method for grating embryo, comprises the steps:

[0022] 1) Prepare the mould, prepare the bamboo thread 4, clean the mold group and the bamboo thread 4 for later use;

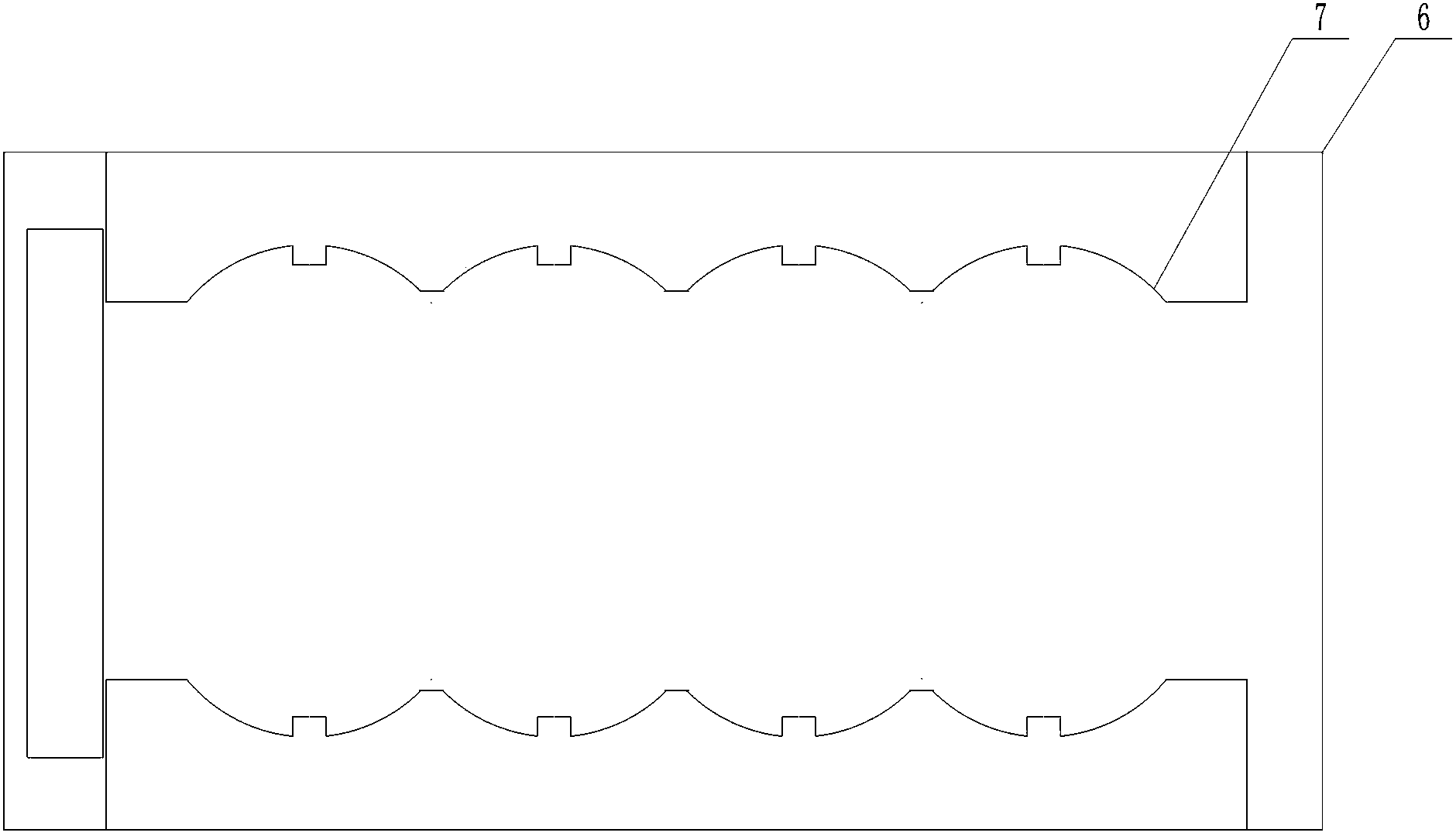

[0023] 2) Arrangement, set the second row of silk molds 2 and the third row of silk molds 3 in the mold group on the left and right sides of the first row of silk molds 1, and then put the bamboo filaments 4 in sequence and correspondingly into the first row. The wire row mold 1, the second wire row mold 2, and the third wire row mold 3 are placed in the groove 5 in the same arrangement position, and are turned over 180° as a whole and then moved into the shaping mold 6;

[0024] 3) Shaping and gluing, place the first row of wire mold 1 in the frame 7 of the same size as the shape of the grate in the shaping mold 6, and move the second row of wire mold 2 and the third row of wire mold 3 to the left and right sides. The length of the bamboo wire of the grate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com