Electrochemical Machining Method for Surface Texture of High Potential Inert Metal Template

A technology of inert metal and surface texture, applied in metal processing equipment, electrochemical processing equipment, manufacturing tools, etc., can solve the problem of large texture size and achieve the effect of narrowing the scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

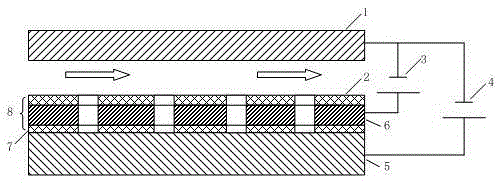

[0034] combine figure 1 The schematic diagram of the electrolytic machining method for the surface texture of the high potential inert metal template is shown, and the electrolytic machining method for the surface texture of the potential inert metal template includes the following steps:

[0035] (a) Make a template 8 with a through hole structure, the template 8 is composed of an insulating layer A2 covering the upper surface of the inert metal sheet 6 in contact with the electrolyte, and an insulating layer A2 covering the lower surface of the inert metal sheet 6 in contact with the workpiece anode 5 And the inert metal sheet 6 consists of three parts;

[0036] (b) Closely fit the template 8 and the workpiece anode 5;

[0037] (c) The negative poles of power supply A3 and power supply B4 are connected to the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com