A dynamic closed automatic deformation test system of a high temperature tester

A technology of deformation testing and high-temperature testing, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problems of sample oxidation and inability to meet various atmospheric conditions, and achieve the goal of improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

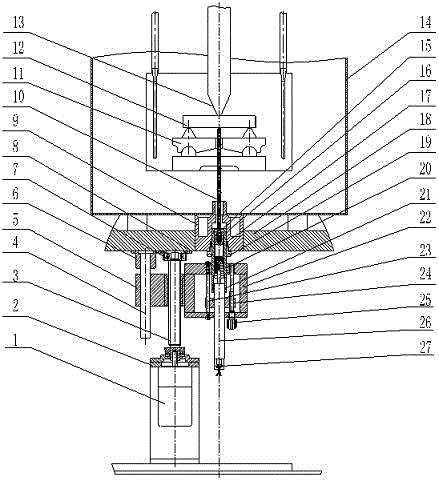

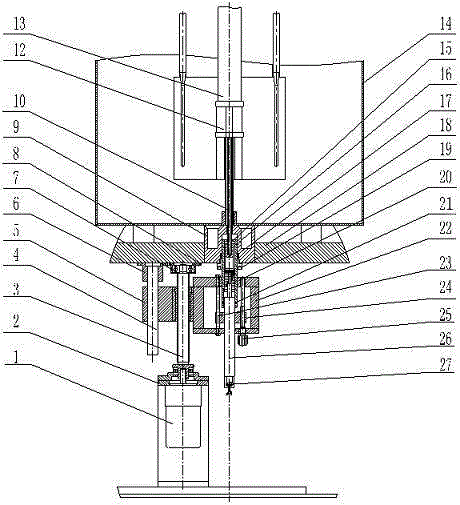

[0026] Embodiment 1 is an automatic deformation testing system of a controlled-atmosphere high-temperature three-point bending six-sample stress-strain tester.

[0027] The high-temperature test furnace body 14 of the tester is a sealed furnace body, that is, the metal shell adopts a full welding process to seal all seams, and the furnace mouth and other parts that need to be opened are fastened and sealed with sealing rings and metal clips. The test furnace system is equipped with Ventilation devices, vacuum devices, pressure vacuum gauges, thermocouples for temperature measurement, etc. for introducing protective atmosphere. Six strip samples 12 are loaded in the test furnace, and a displacement sensor measuring rod 10 for measuring deformation is installed below the central part of the lower surface of the first strip sample 12. The scheme of the present embodiment 1 is, in the displacement sensor device A sealing mechanism is arranged on the periphery of the furnace body, ...

Embodiment 2

[0049] Embodiment 2 is an automatic deformation testing system of a controllable atmosphere high temperature load soft creep tester. On the basis of Example 1, the sample is a cylindrical sample 12 with a through hole in the center according to the national standard GB / T5989-2008 "Refractory Material Load Softening Temperature Test Method Differential Heating Method", cylindrical sample 12 Gaskets are placed on the upper and lower end surfaces of the upper and lower gaskets, the upper gasket has no holes, the lower gasket has a central hole of the same size, and the lower gasket is placed on the lower support rod with the same central hole set according to the standard. The upper end of the measuring rod 10 Through the lower support rod, the lower gasket and the central hole of the cylindrical sample 12, it contacts the lower surface of the upper gasket.

[0050] Work points:

[0051] Place the lower gasket with the central hole on the lower support rod with the central hol...

Embodiment 3

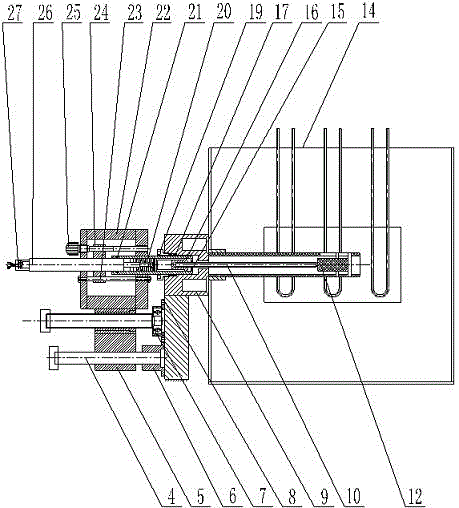

[0058] Embodiment 3 is an automatic deformation testing system of a controlled-atmosphere high-temperature thermal expansion tester. On the basis of Example 1, according to the national standard GB / T7320-2008 "Refractory Thermal Expansion Test Method", the high-temperature test furnace furnace body 14 is a horizontal horizontal sealing body, and the test furnace system is provided with aeration device, vacuum Devices, pressure vacuum gauges, temperature measuring thermocouples, etc. Cylindrical sample 12 is horizontally placed in the sample loading tube, the measuring end of sample 12 is in contact with measuring rod 10 for measuring deformation, the outer end of measuring rod 10 is displacement sensor 26, and sealing mechanism is arranged on the periphery of displacement sensor device, described The sealing mechanism is arranged on the moving frame 22 outside the furnace body 14, and a driving mechanism for driving the moving frame 22 is arranged on one side of the moving fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com