Chain for agricultural harvester and chain accessory for agricultural harvester

A harvester and chain technology, applied in the direction of the transmission chain, etc., can solve the problems of poor stability, easy falling off, chain wear, etc., and achieve the effect of enhancing the service life, enhancing the firm strength, and being convenient for replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

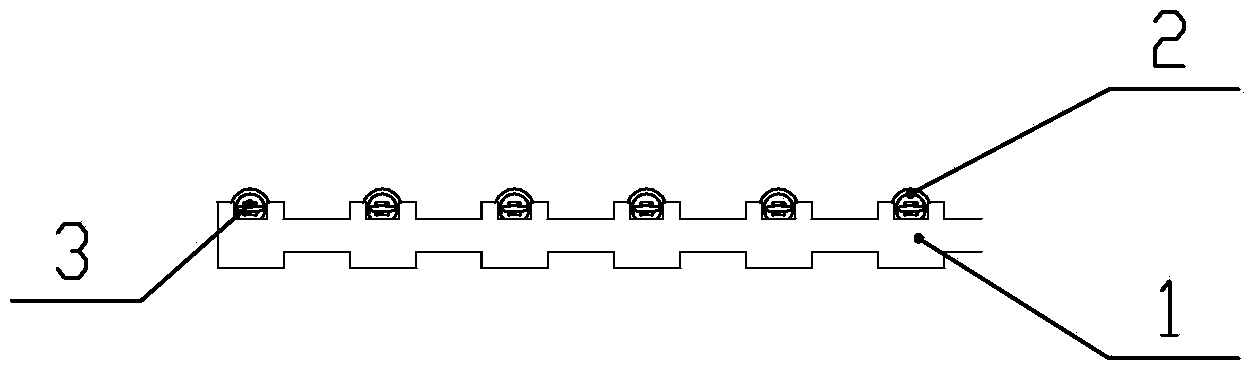

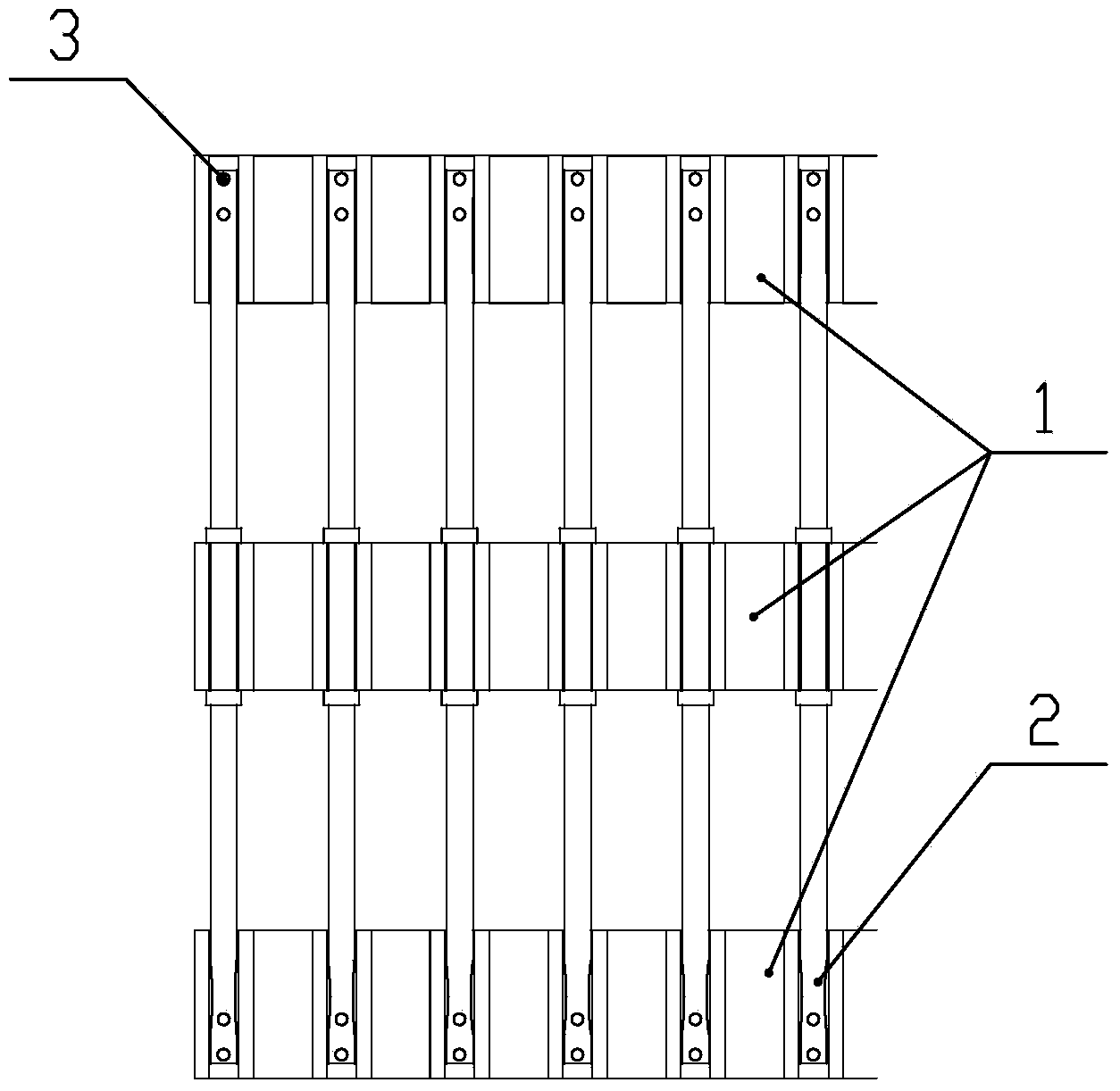

[0040] see Figure 5-Figure 6 , the present embodiment is used for the chain of the agricultural harvester, including a plurality of longitudinally arranged shaft rollers 8 and three chains arranged side by side and evenly spaced on the shaft rollers 8, each chain includes a plurality of chain link units, each The link units each include a first link and a second link, wherein the first link includes two first connecting link plates 12 arranged side by side, and the second link includes two second connecting link plates 11 arranged side by side , the shaft-roller connecting portion 111 extending from the second connecting chain plate 11 for connecting the shaft-roller 8 and the fixing plate 112 connecting the two shaft-roller connecting portions 111, the second chain link is in a U-shaped structure, and the second connecting chain The plate 11, the fixed plate 112 and the shaft-roller connecting portion 111 are connected in one structure, the adjacent first connecting chain pl...

Embodiment 2

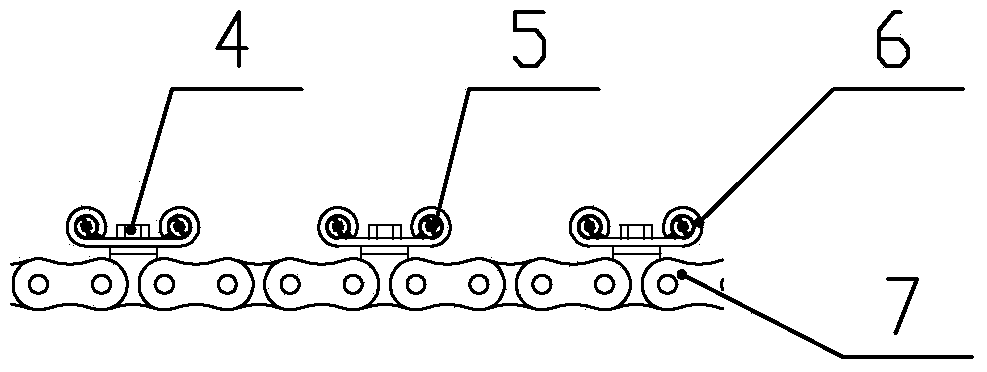

[0042] see Figure 7 , the present embodiment is used for a chain accessory of an agricultural harvester, including a plurality of chain link units, each of which includes a first chain link and a second chain link, wherein the first chain link includes two side-by-side second chain links A connecting chain plate 12, the second chain link includes two second connecting chain plates 11 arranged side by side, a shaft-roller connecting portion 111 extending from the second connecting chain plate 11 for connecting the shaft roller and connecting two shaft rollers The fixing plate 112 of the connecting portion 111, the second chain link is in a U-shaped structure, the second connecting chain plate 11, the fixing plate 112 and the shaft-roller connecting portion 111 are integrally connected, the adjacent first connecting chain plate 12 and the second The two connecting chain plates 11 are connected by a pin shaft 15 , and a shaft-roller connecting hole 113 is opened on the shaft-rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com