Crankshaft connecting rod assembly

A crankshaft connecting rod and assembly technology, which is applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of increased wear of needle roller bearings, seizure, and affecting the service life of the crankshaft connecting rod assembly, etc., to achieve processing Simple manufacture, less oil pollution, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

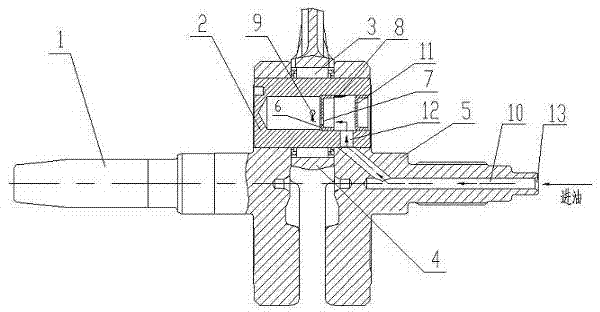

[0017] Referring to accompanying drawing 1, the crankshaft connecting rod assembly shown in the embodiment of the present invention includes a left crank 1, a right crank 5 and a connecting rod 4, the connecting rod 4 is located between the left crank 1 and the right crank 5, and passes through the crank The pin 2 is connected with the left crank 1 and the right crank 5; a needle bearing 3 is arranged between the crank pin and the connecting rod; there is a cavity in the crank pin 2, and an oil plug 11 is installed on one side of the cavity, and there is an oil plug 11 in the right crank. The oil channel 10 of the above-mentioned cavity is connected through the inclined oil hole 12, and the above-mentioned cavity is also opened with a small oil hole 9 connected to the needle bearing 3. It is characterized in that it also includes an oil separator 6 installed in the above-mentioned cavity. , the oil separation part is a bowl with a separation oil hole 7 at the bottom, which is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com