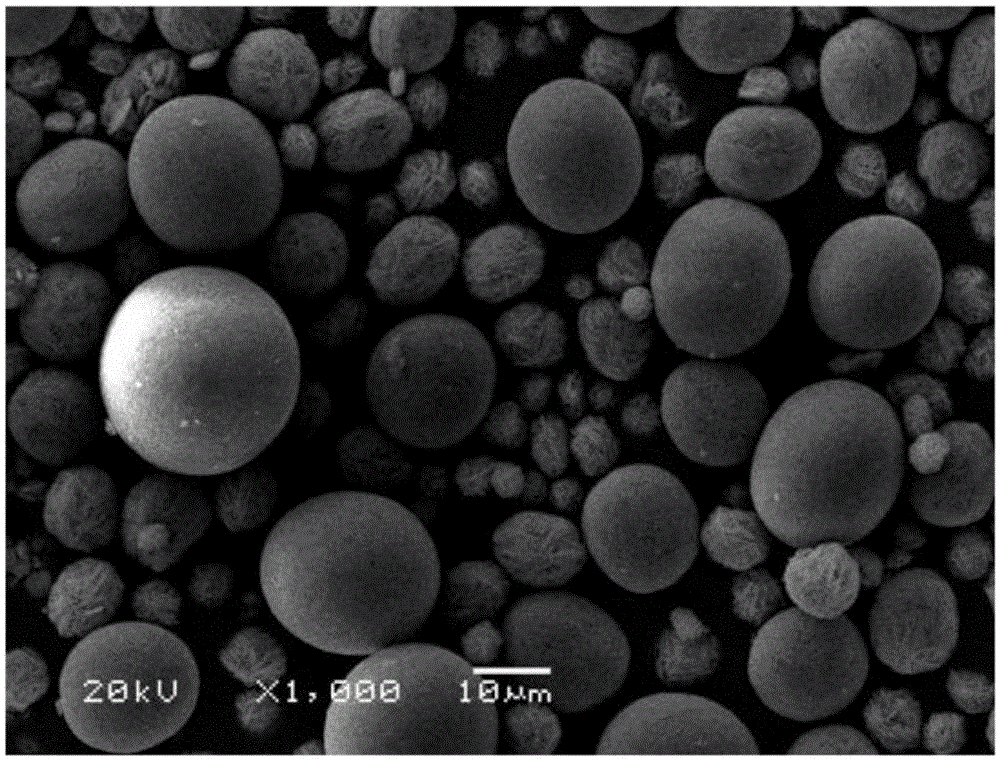

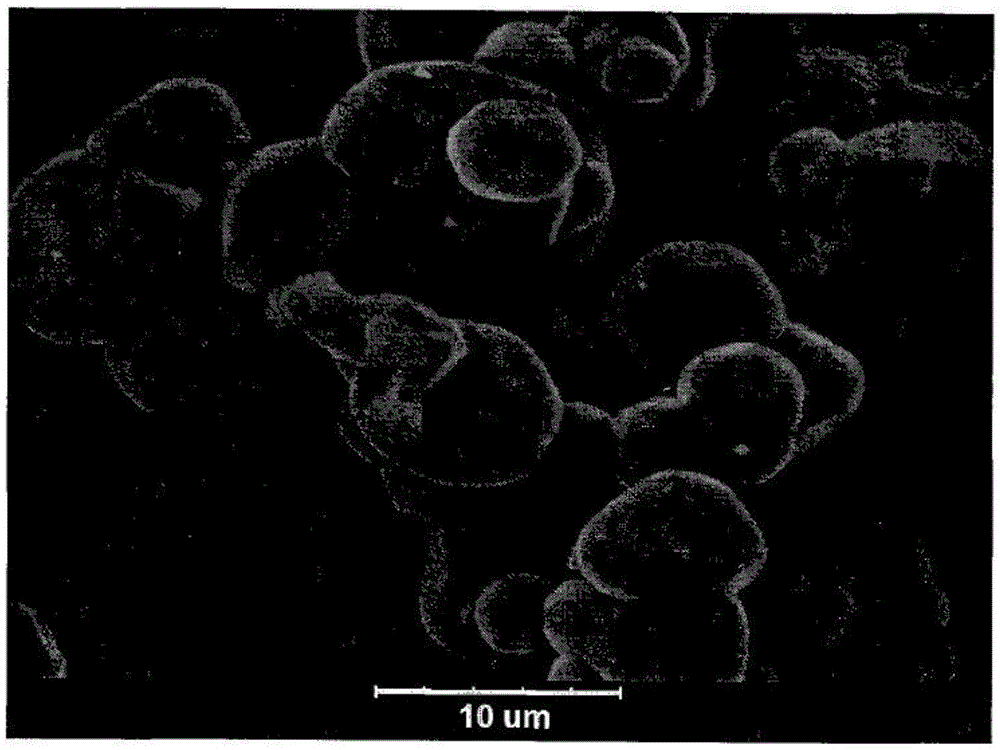

A kind of preparation method of large particle spherical cobalt tetroxide

A technology of tricobalt tetroxide and large particles, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of insufficient sphericity, easy consumption of electrode materials, and low energy density of lithium cobalt oxide electrodes, so as to achieve high energy density, improve energy density and The effect of using performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Prepare 1.0mol / L cobalt sulfate (CoSO 4 ) aqueous solution;

[0028] (2) Prepare 4.0mol / L sodium hydroxide aqueous solution;

[0029] (3) Prepare a mixed solution of ethylenediamine and hydrazine hydrate with deionized water, and the mixed solution contains 0.3mol / L ethylenediamine and 0.05mol / L hydrazine hydrate;

[0030] (4) The above cobalt sulfate (CoSO 4 ) solution, sodium hydroxide solution and mixed solution were added to the reaction kettle at a flow rate of 250L / h, 100L / h and 50L / h respectively, the reaction temperature was controlled at 40°C, the reaction pH was 9, and the stirring speed was 700rpm / min, react for 12h to prepare the precursor;

[0031] (5) The above precursor was washed with deionized water, filtered, and then calcined at 800°C for 6 hours to obtain tricobalt tetroxide A.

Embodiment 2

[0033] (1) Prepare 1.0mol / L cobalt chloride (CoCl 2 ) aqueous solution;

[0034] (2) Prepare 5.0mol / L sodium hydroxide aqueous solution;

[0035] (3) Prepare a mixed solution of EDTA and sodium thiosulfate with deionized water, the mixed solution contains 0.5mol / L of EDTA and 0.1mol / L of sodium thiosulfate;

[0036] (4) The above cobalt chloride (CoCl 2 ) solution, potassium hydroxide solution and mixed solution were added to the reaction kettle at a flow rate of 150L / h, 150L / h and 40L / h respectively, the reaction temperature was controlled at 50°C, the reaction pH was 10, and the stirring speed was 900rpm / min, reacted for 13h to prepare the precursor;

[0037] (5) The above precursor was washed with deionized water, filtered, and then calcined at 800°C for 5 hours to obtain tricobalt tetroxide B.

Embodiment 3

[0039] (1) Prepare 2.0mol / L cobalt sulfate (CoSO 4 ) aqueous solution;

[0040] (2) Prepare 6.0mol / L potassium hydroxide aqueous solution;

[0041] (3) Prepare tartaric acid and hydrazine hydrate with deionized water to prepare a mixed solution containing 1.0 mol / L tartaric acid and 0.15 mol / L hydrazine hydrate;

[0042] (4) The above cobalt sulfate (CoSO 4 ) solution, potassium hydroxide solution and mixed solution were added to the reaction kettle at a flow rate of 100L / h, 120L / h and 30L / h respectively, the reaction temperature was controlled at 60°C, the reaction pH was 11, and the stirring speed was 1000rpm / min, react for 14h to prepare the precursor;

[0043](5) The above precursor was washed with deionized water, filtered, and then calcined at 700°C for 4 hours to obtain tricobalt tetroxide C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com