Turning over spreader for wind turbine impeller assembly

A technology of wind turbines and spreaders, applied in the field of wind power, which can solve problems such as irregular hubs, difficult and difficult connections of spreaders, etc., and achieve the effects of convenient use and maintenance, flexible and convenient disassembly, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

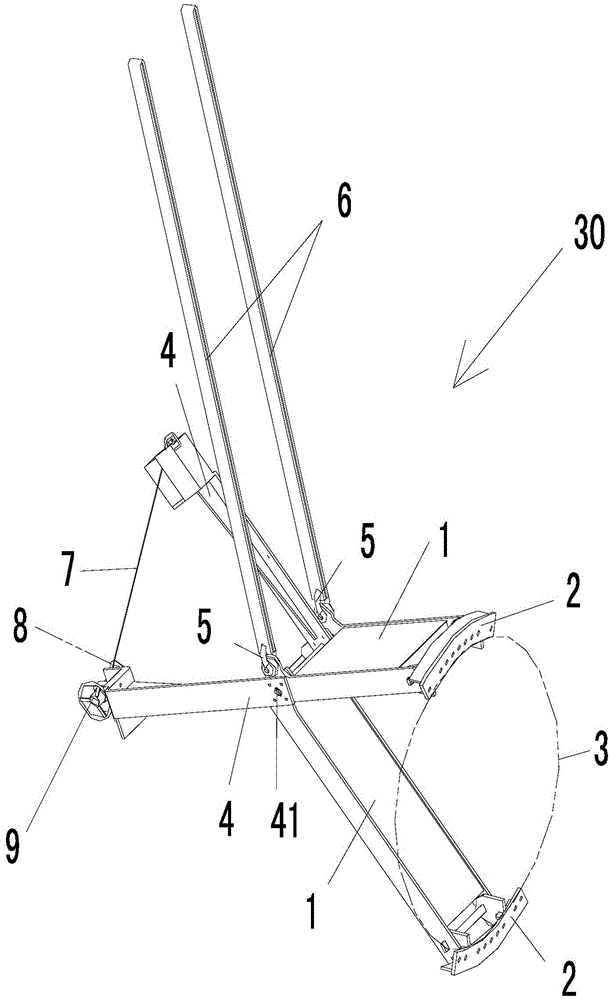

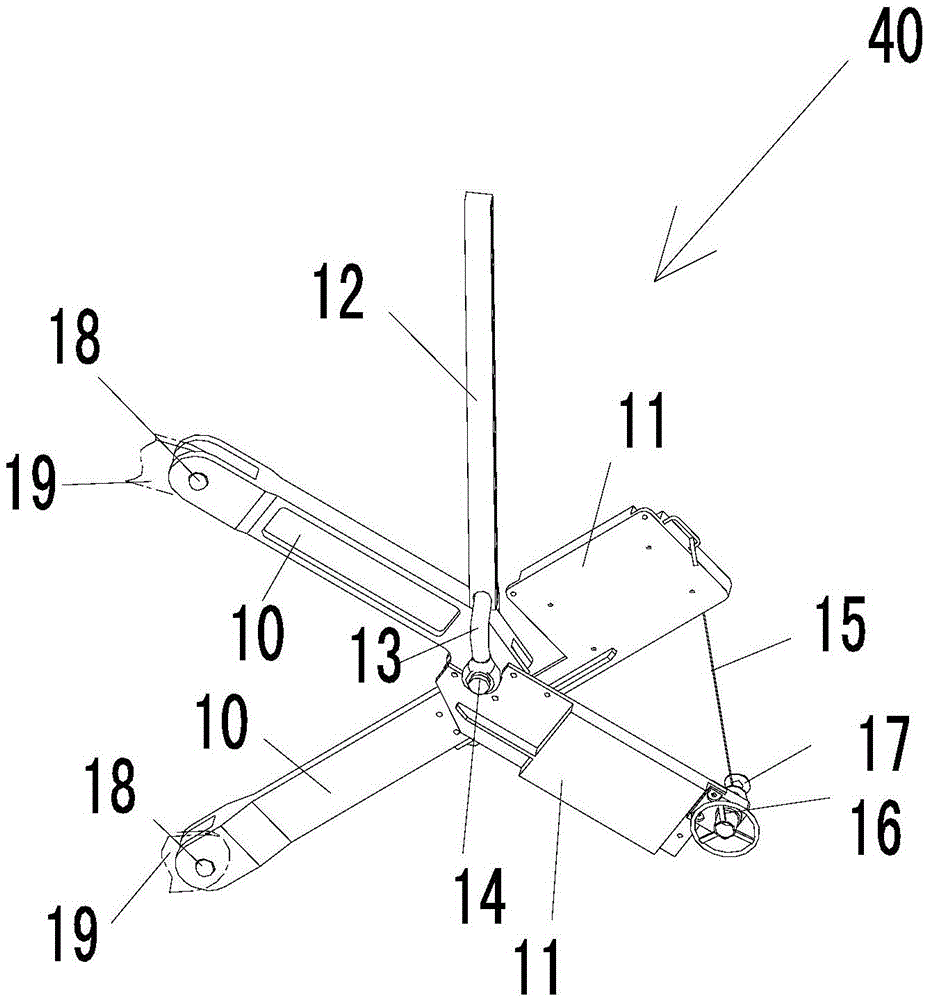

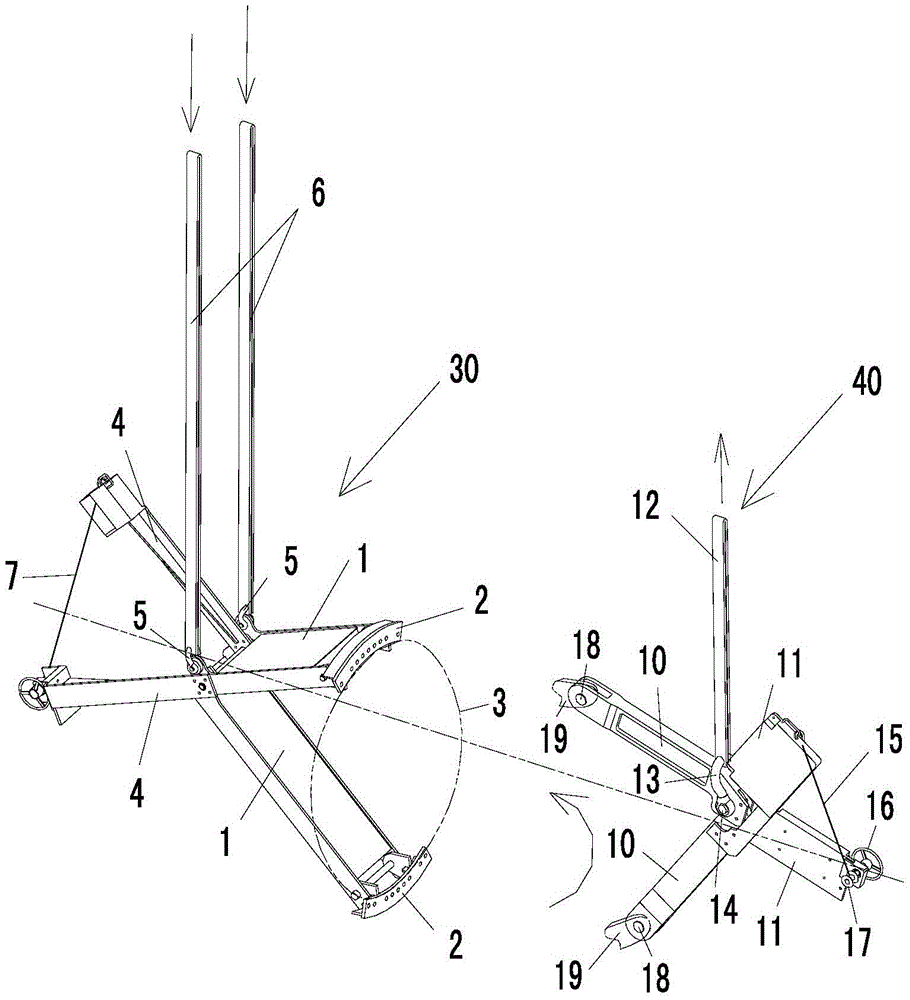

[0025] As the impeller hub hoisted by the stand-up spreader provided by the present invention, the state of being transported to the site before hoisting is to be arranged on a support in a glass fiber reinforced plastic shroud, and the flange end face connected to the engine shaft of the nacelle is set downwards. The pitch bearing ends of the three blades are evenly arranged on the side of the hub of the impeller. Cooperating with the hanger provided by the present invention, a hoisting structure is arranged on the outer wall of the hub between the pitch bearing ends 3 of the two blades of the impeller hub. Specifically, the hoisting structure is an impeller hub lifting lug 19 , and pin shaft holes are arranged on the lifting lug 19 . On the wind deflector (not shown in the figure), two windows are opened at the corresponding lifting lug 19 and a pitch bearing end opposite to the lifting lug 19, for the hoisting sling to stretch into the wind deflector and hold the impeller h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com