A lifting and reciprocating transmission system for body assembly and welding

A transmission system and vehicle body technology, which is applied in the field of automobile manufacturing, can solve the problems of high manufacturing cost of conveying devices, difficulty in controlling the production cycle, and low degree of automation, and achieve the effects of low manufacturing cost, easy control of transmission distance, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any changes or improvements made based on the teaching of the present invention belong to the protection scope of the present invention.

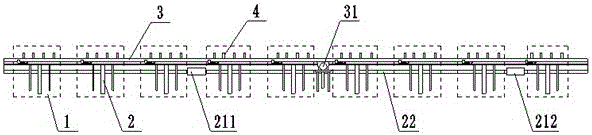

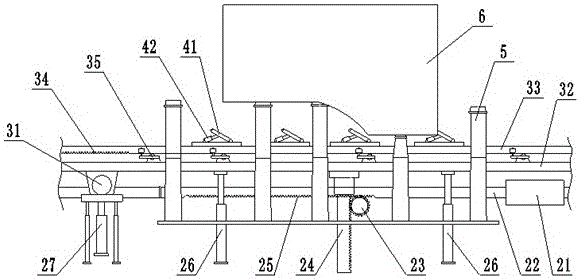

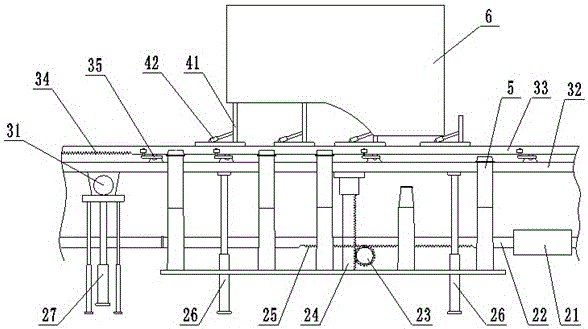

[0022] Such as Figure 1~3 As shown, the present invention comprises more than 3 stations 1 for assembling and welding the vehicle body 6, each station 1 is equipped with a fixed support 5 having the same structural size, and the distance between each station 1 is equal, and all stations 1 The lower side of the vehicle body 6 clamping position is equipped with a reciprocating transmission mechanism 3 that can be integrally lifted and horizontally reciprocated. The beam 33 and the support beam 32 are both slab-type monorail support beams with sufficient strength. The walking beam 33 is movably installed on the upper side of the support beam 32. A roller part 35 is installed between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com