A Control Method of Electrohydraulic Braking System Based on Two Degrees of Freedom Differential Gear Train

A differential gear train and hydraulic braking technology, applied in the automotive field, can solve the problem of high control difficulty and achieve the effects of reasonable coupling, maximizing recovered energy and good brake pedal feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

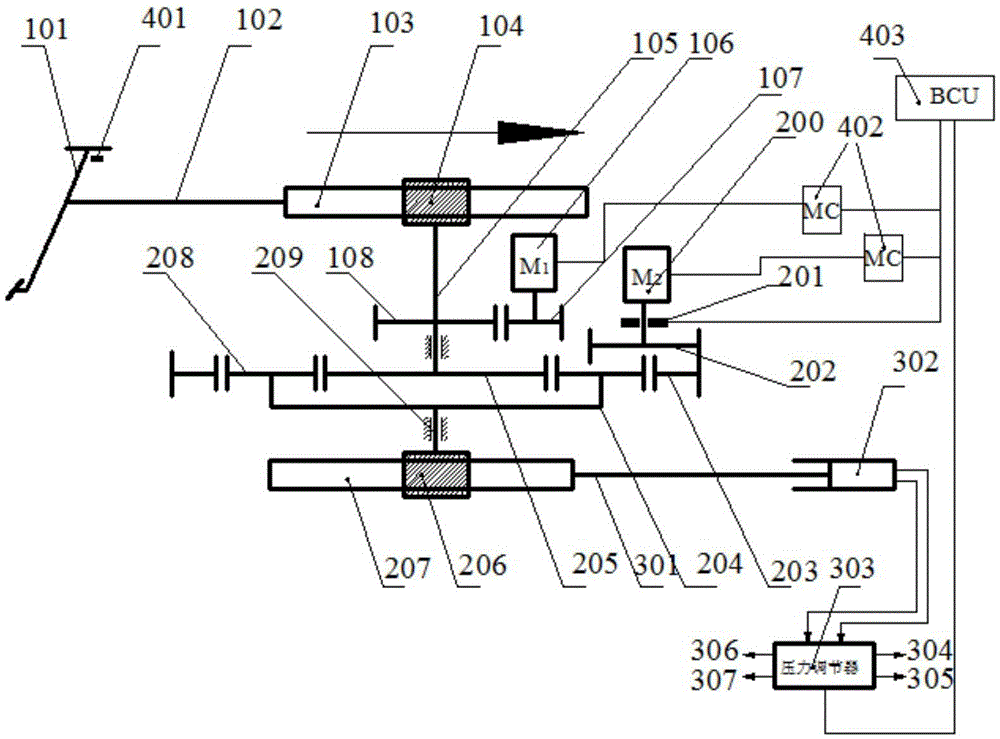

[0035] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

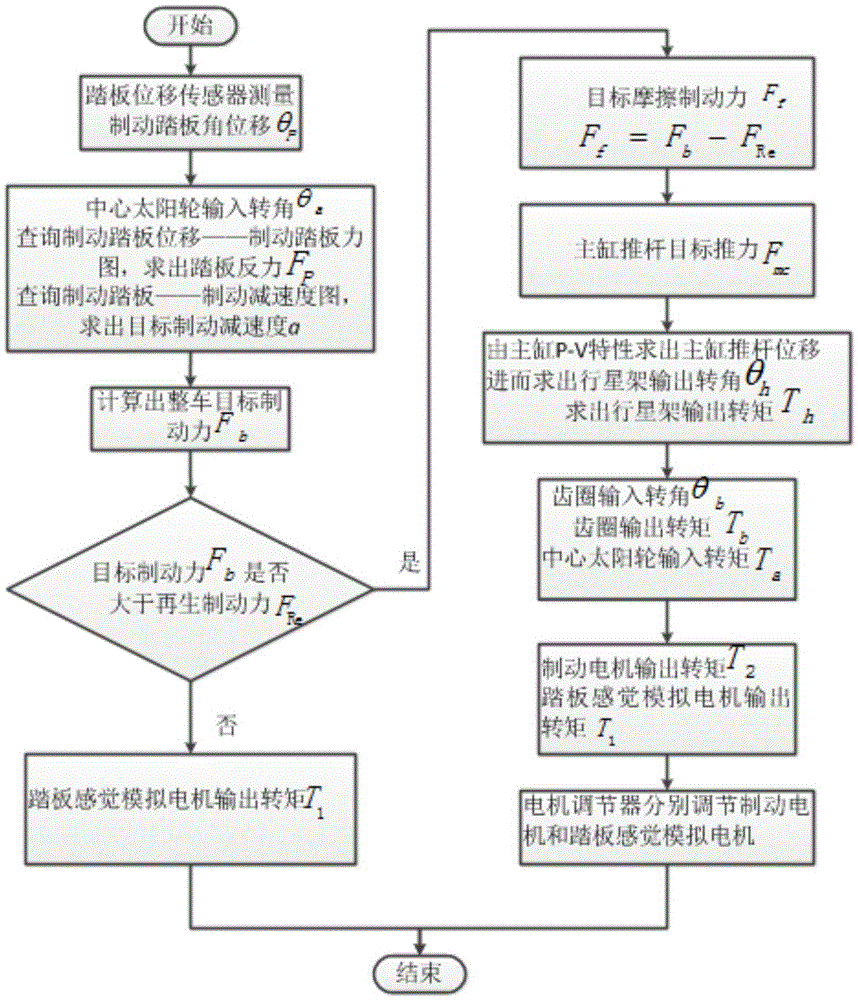

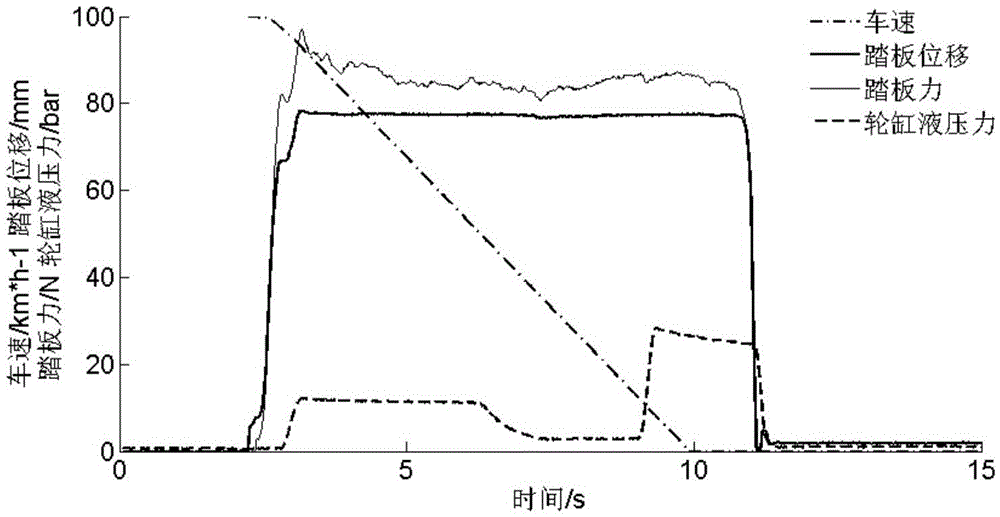

[0036] Such as figure 2 As shown, the electronic hydraulic braking system control method based on the two-degree-of-freedom differential gear train mainly includes: the brake pedal feeling simulation motor control logic, through the control of the motor torque in the brake pedal feeling simulation mechanism, for the brake pedal Provide a certain pedal feedback force to simulate the feeling of the brake pedal, and also provide a certain input torque for the active pressure building and regulating mechanism; brake motor control logic: through the motor torque and motor rotation angle in the active pressure building and regulating mechanism Then, according to the input torque-output torque relationship of the two-degree-of-freedom differential gear train, the brake master cylinder thrust is obtained, and at the same time, combined with the regene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com