Elevator transmission frame welding and positioning device and welding method thereof

A welding positioning and transmission frame technology, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems that the positioning accuracy of the elevator transmission frame cannot be guaranteed, the welding accuracy affects the safe operation of construction elevators, and the safety hazards of construction elevators, etc. , to achieve the effect of eliminating potential safety hazards, improving welding efficiency, and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific embodiments and related drawings.

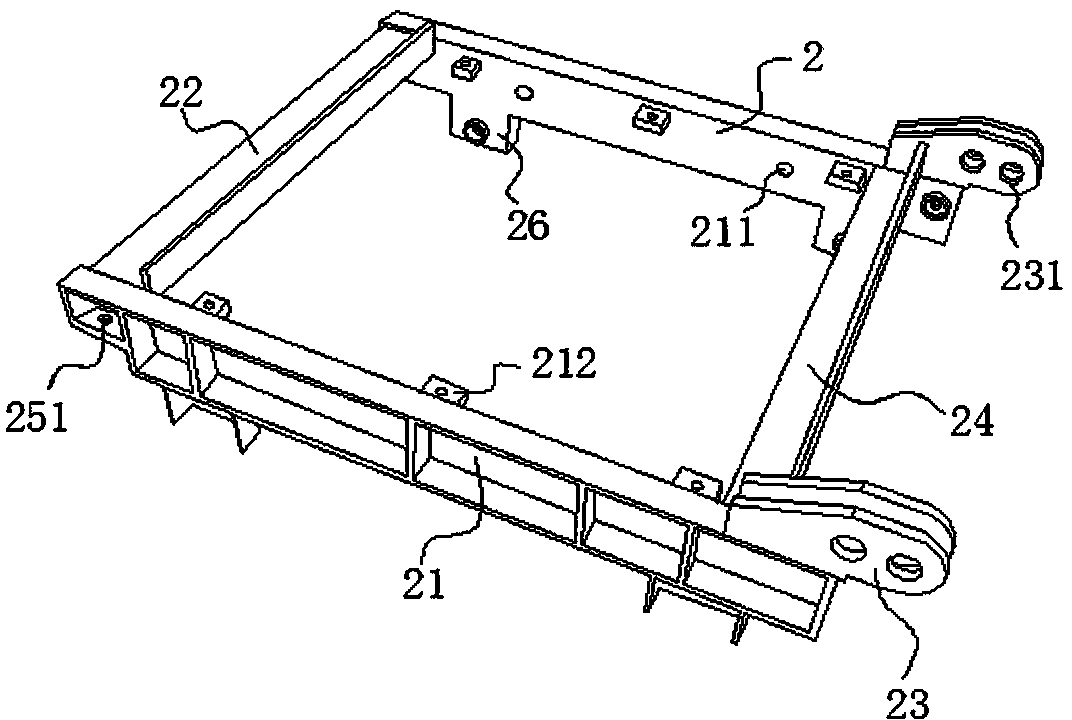

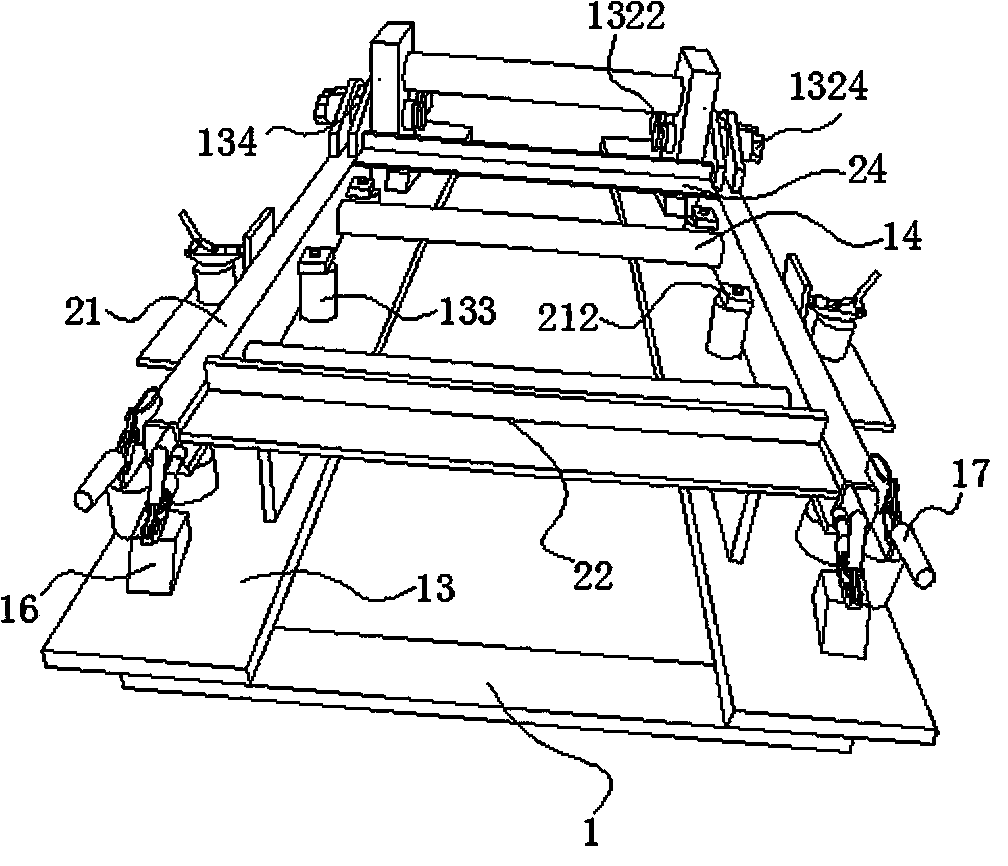

[0020] Such as figure 2 and Figure 4 It shows the structure of the elevator transmission frame, including the fixed frame 21 located on both sides of the transmission frame 2 and the front angle steel 24 and the rear angle steel 22 located on the front and rear sides of the transmission frame 2. A pair of lugs 23 are respectively provided on both sides of the front end of the fixed frame 21, The fixed frame 21 is provided with several connecting blocks 25 arranged along the length direction, and the connecting block 25 is provided with bolt holes B (2121), and a pair of supporting feet 26 are provided under the fixed frame, and the rear end of the fixed frame 21 The lower side is provided with a connecting plate 25, the connecting plate 25 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com