Integrated desoldering system conducting upper hot air heating and lower hot air heating synchronously

A hot air and heating head technology, applied in electric heating devices, metal processing, welding equipment, etc., can solve problems such as not being able to adapt to high-end circuit board assembly production and repair, affecting work quality and production efficiency, and poor local welding of BGA. The effect of desoldering and mounting precision, improving the success rate of welding, and no safety hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present utility model will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

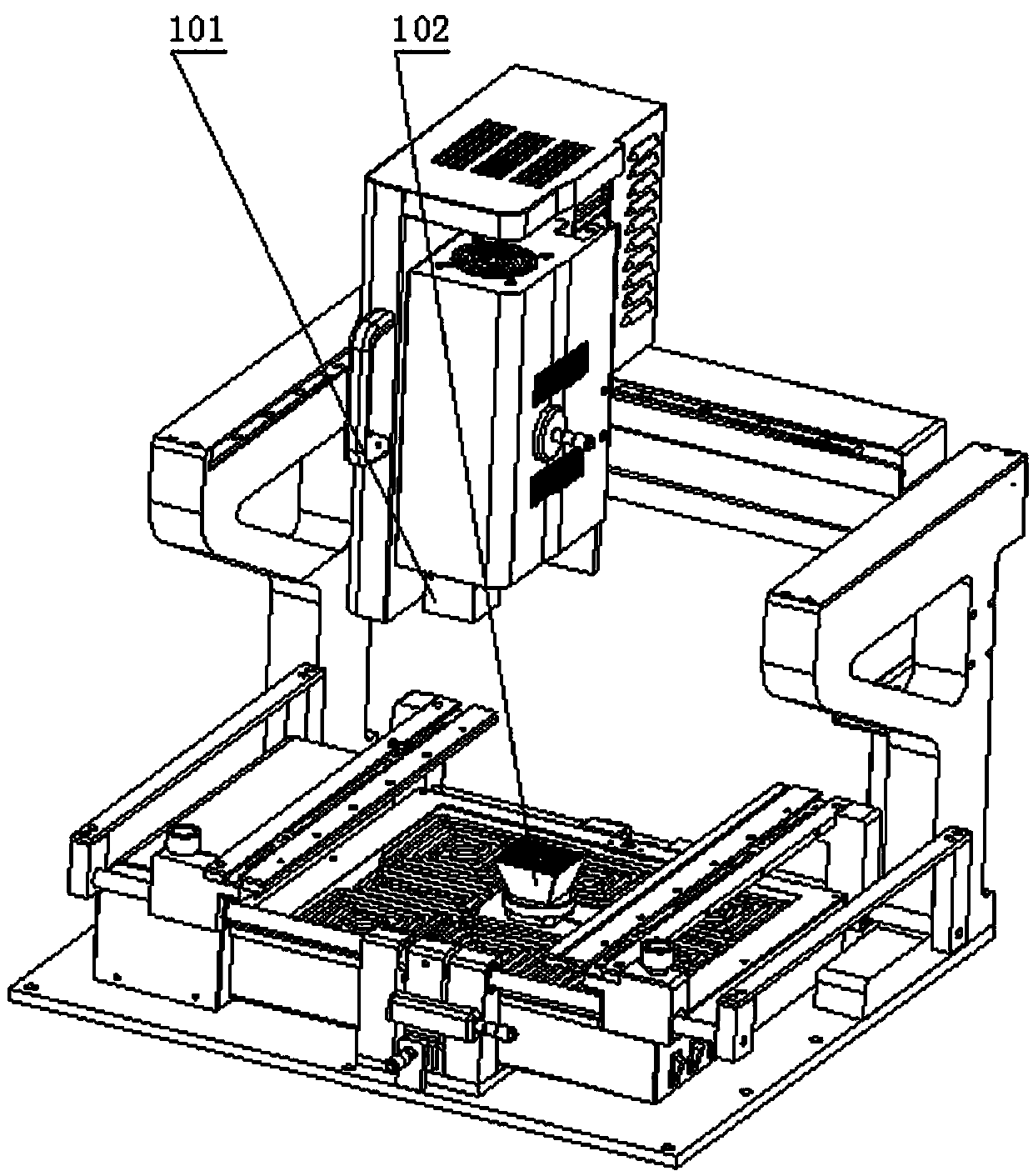

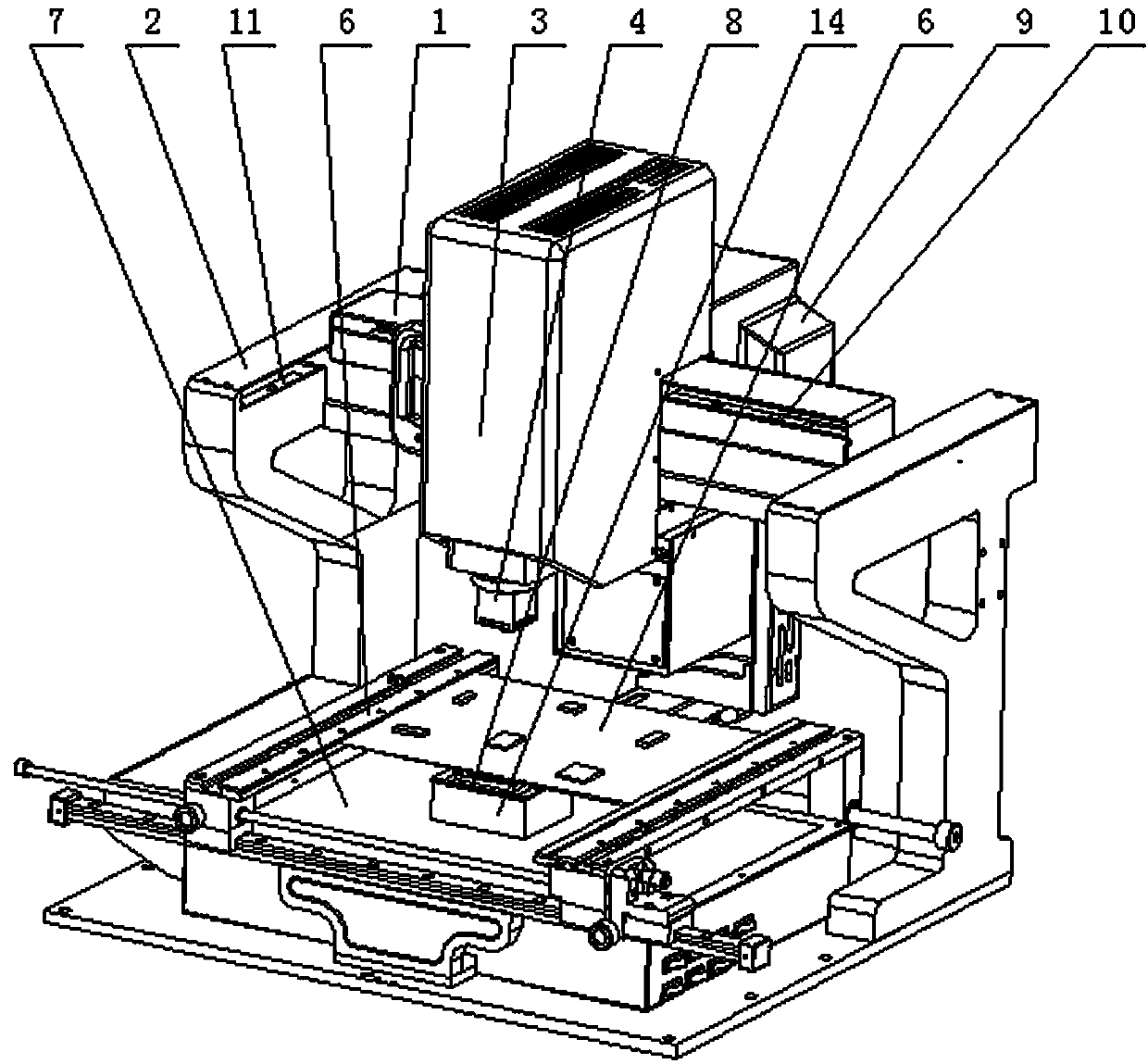

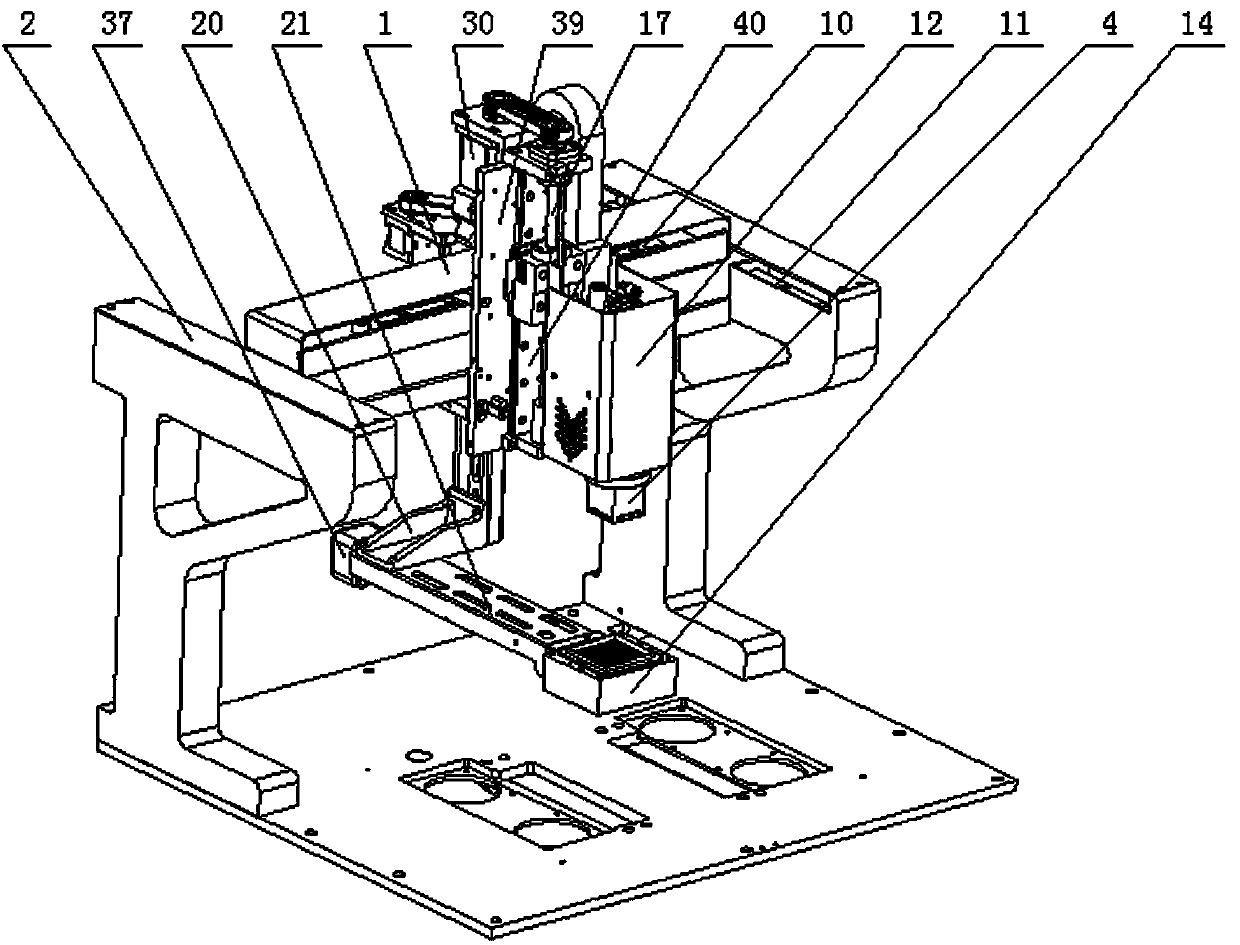

[0031] figure 2 It is a schematic diagram of the implementation structure of the present invention; image 3 It is a schematic diagram of the overall structure of the present invention; Figure 4a , 4b It is a schematic diagram of structural decomposition of the present invention; Figure 5 yes Figure 4a The front view of the structure shown; Figure 6 yes Figure 4a Right view of the structure shown; Figure 7 is a picture Figure 6 Section A-A is shown. Depend on figure 2 to combine image 3 ,Figure 4, Figure 5 , Figure 6 , Figure 7 It can be seen that the integrated desoldering system with synchronous heating of upper and lower hot air is mainly composed of an upper heating device, a lower heating device and a synchronization mechanism, wherein the upper heating device consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com