Wedge-lock-type bidirectional locking mechanism of pull tower

A technology of locking mechanism and wedge lock, which is applied in the field of pulling tower locking mechanism, can solve the problems of affecting mobility, the weight of pulling tower, and increasing manufacturing cost, etc., and achieve the effect of function improvement, elimination of easy movement, and excellent maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

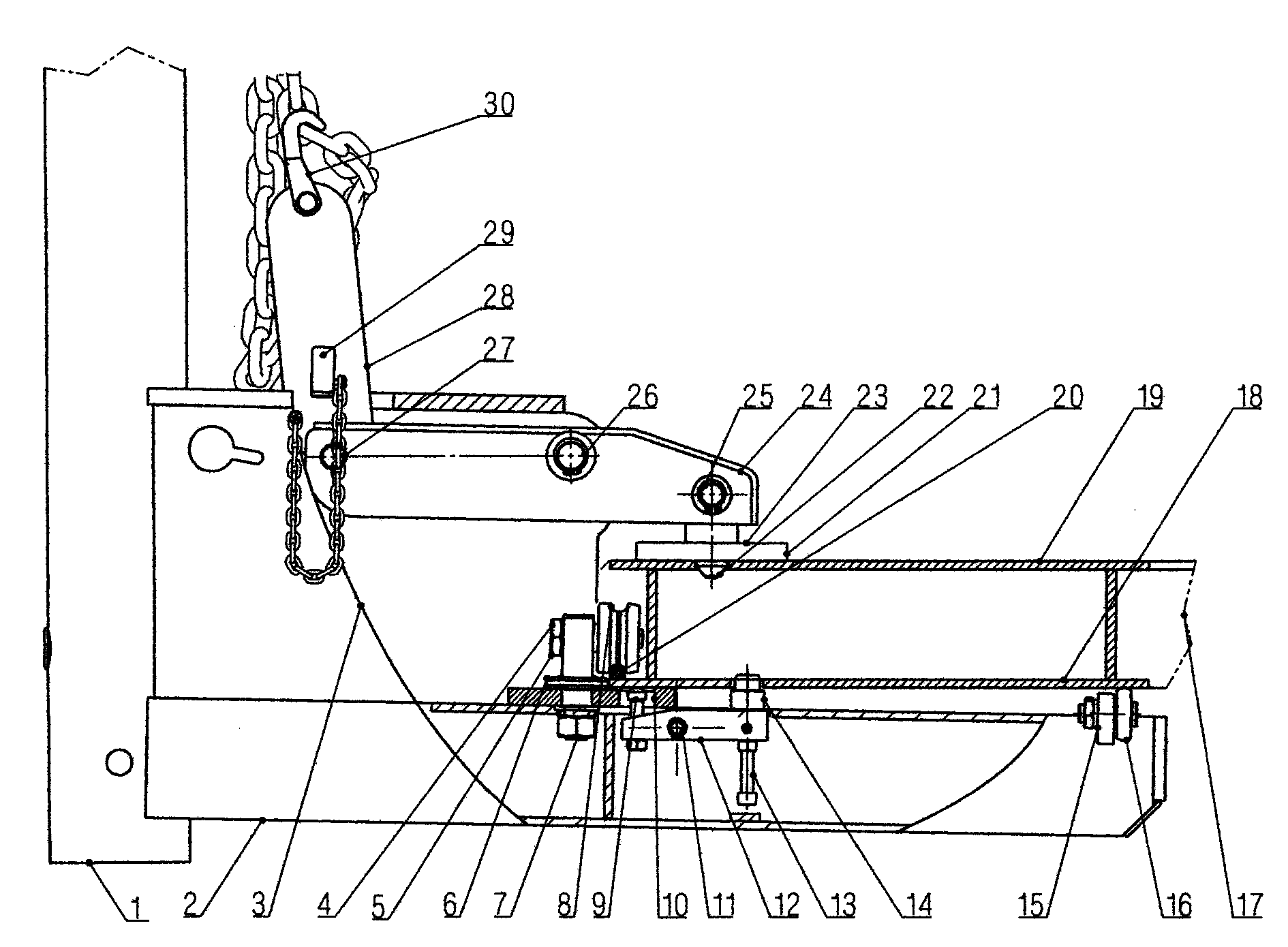

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

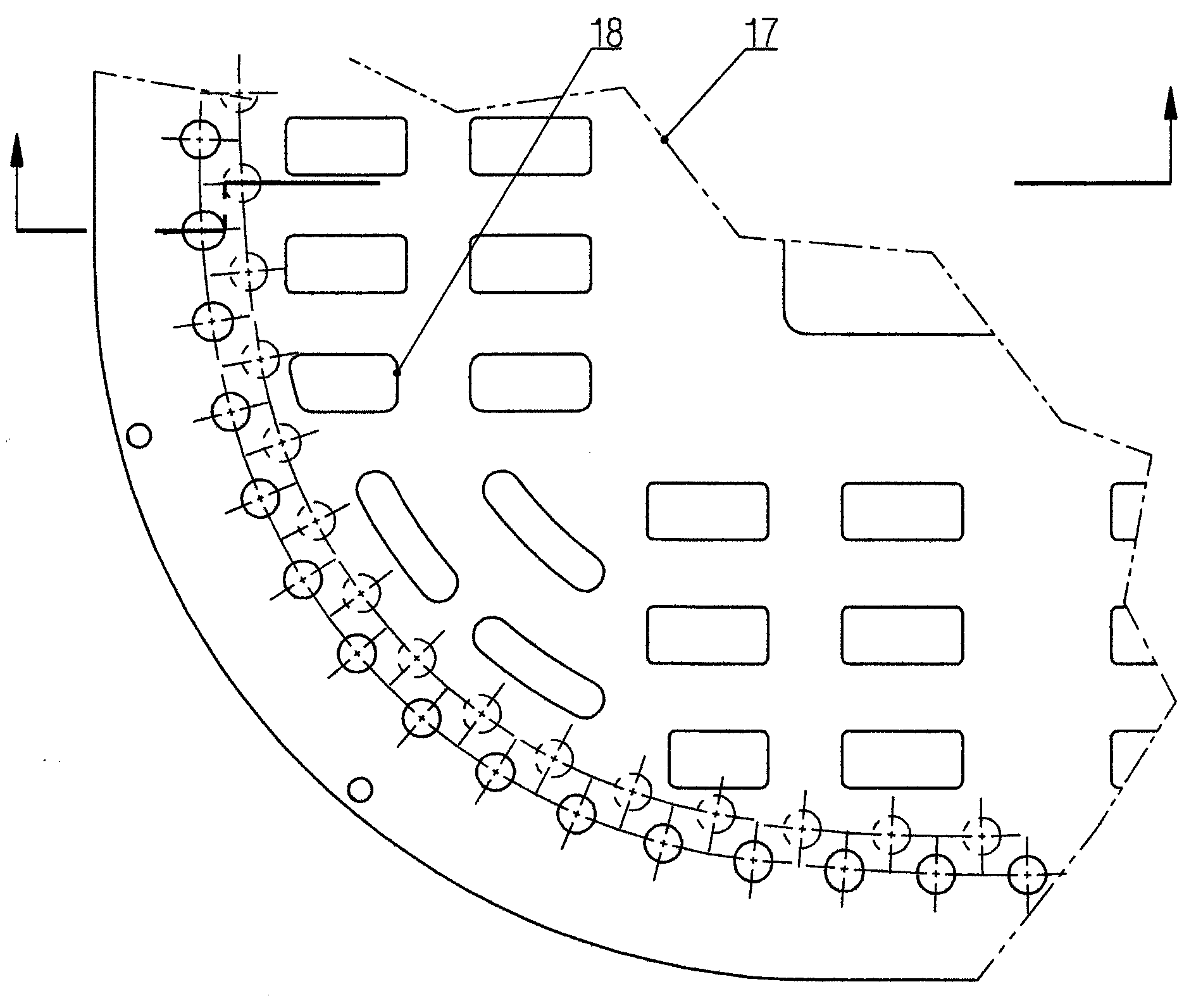

[0029] like figure 1 , the embodiment of the present invention includes the tower arm 2 and the tower column 1 of the tower, and the upper frame 3 is fixedly installed in the inner corner area of the tower arm 2 and the tower column 1 .

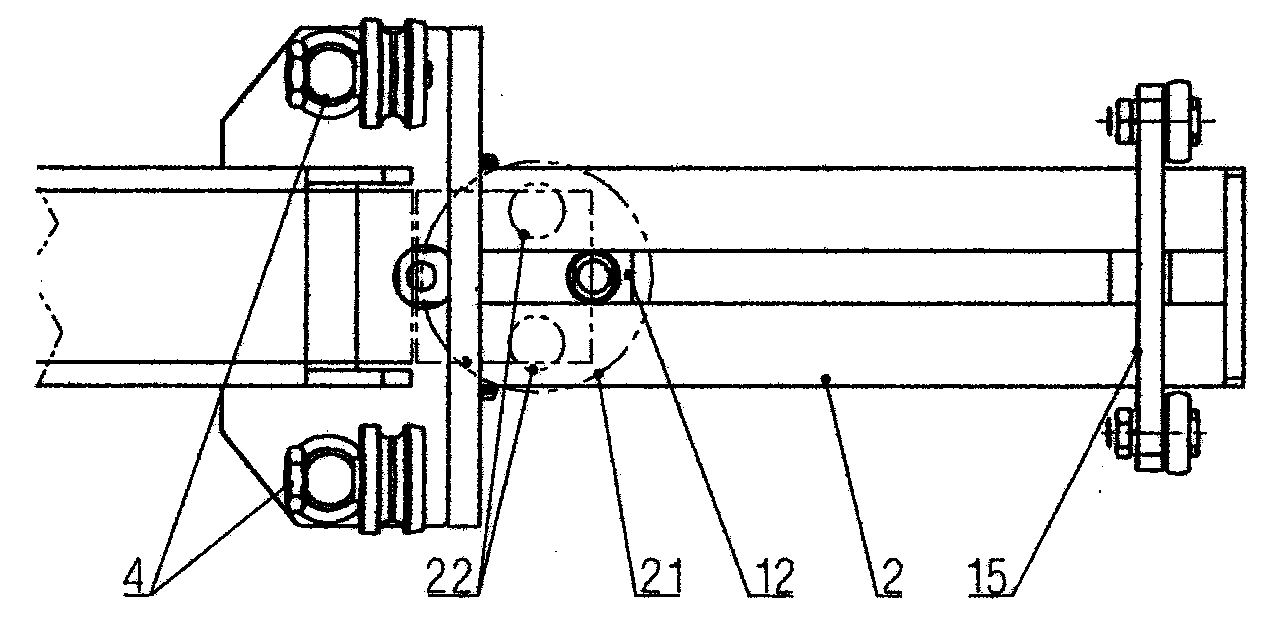

[0030] like figure 1 , figure 2 and Figure six , also includes the lower arm 12 arranged in the notch set on the top surface of the tower arm 2, located in front of the upper frame 3 and connected to the tower arm 2 through the first hinge shaft 11, the first hinge shaft 11 is located on the lower arm 12 back position. The top of the front end of the lower arm 12 is equipped with a touch pin 14 , and the top of the tail end of the lower arm 12 is equipped with a ball screw 9 . A limit screw 13 located at the lower end of the touch pin 14 is also installed on the lower arm 12 .

[0031] still as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com